Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > Double eccentric hemisphere valve

Location:Home > Product Center > Ball Valve > Double eccentric hemisphere valve

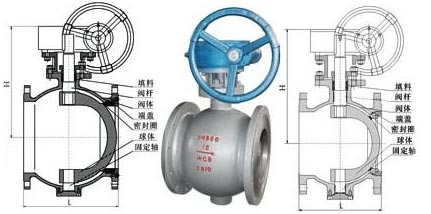

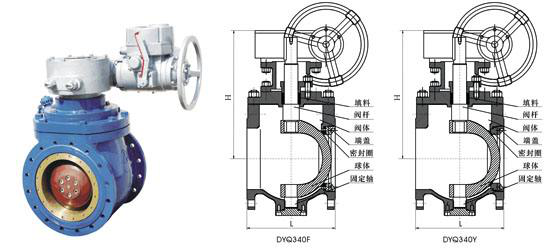

PQ340HThe products of side mounted double eccentric hemisphere valve can be divided into six series according to their applications: general valve, pipeline valve, slurry valve, gas valve, Petrochemical valve and pulverized coal injection valve. Eccentric hemisphere valve transmission mode has manual, pneumatic, electric three kinds. Eccentric hemisphere valve is also known as C-type ball valve, which makes the valve unblocked or blocked by rotating hemisphere. Its switch is light, small volume, can be made into a large diameter, reliable sealing, simple structure, convenient maintenance, sealing surface and spherical surface are often closed, not easy to be eroded by the medium. It is widely used in petroleum, chemical industry, urban water supply and drainage, etc.

PQ340HThe products of side mounted double eccentric hemisphere valve can be divided into six series according to their applications: general valve, pipeline valve, slurry valve, gas valve, Petrochemical valve and pulverized coal injection valve. Eccentric hemisphere valve transmission mode has manual, pneumatic, electric three kinds. Eccentric hemisphere valve is also known as C-type ball valve, which makes the valve unblocked or blocked by rotating hemisphere. Its switch is light, small volume, can be made into a large diameter, reliable sealing, simple structure, convenient maintenance, sealing surface and spherical surface are often closed, not easy to be eroded by the medium. It is widely used in petroleum, chemical industry, urban water supply and drainage, etc.

The double eccentric hemisphere valve drives the valve shaft to rotate 90 ° by means of driving mechanism. At this time, the eccentric disc (hemisphere) fixed on the valve shaft rotates 90 ° synchronously. Clockwise rotation, eccentric disc into the valve seat, under the eccentric action to form a wedge-shaped mechanism. The disc gradually compresses the valve seat to achieve sealing and close the valve. When the valve is rotated anticlockwise, the eccentric disc will quickly leave the valve seat, and the valve will be fully open when it is rotated 90 degrees.

1. The eccentric hemispherical valve solves the problems of slurry, mixed flow liquid, dust and other media in pipeline transportation, easy to scale and block, which makes the valve not close tightly.

2. The eccentric hemispherical valve is easy to switch on and off. When it is opened, the ball is separated from the shell without any contact. The starting torque is small and the rotation is flexible. When the valve is closed, the squeeze cutting effect between the hemisphere and the valve seat can remove the dirt on the sealing surface, which makes the valve open and close smoothly with high safety factor and good sealing performance. 3. The eccentric structure of the sealing surface enables the spherical surface to automatically compensate for wear and maintain the sealing of the valve with long service life.

4. The eccentric hemispherical valve T-type belongs to wear-resistant hard sealing ball valve. Its sealing pair material is special, and the sealing surface should be treated with special wear-resistant treatment. After treatment, the surface reaches HRC65-72 degrees, so the wear resistance of the valve is particularly good.

5. Eccentric hemisphere valve surface paint, there are room temperature and high temperature two kinds. The imported paint with temperature resistance of 600 ℃ is used at high temperature. After spraying, the paint is not burnt, carbonized and coking at high temperature. No discoloration.

Manufacturing standard: gb12237-1989, ASME B16.34, API6D structure length: according to: gb12221, ASME B16.10

Dimensions of connecting end shall be in accordance with JB / t79, gb9113, hg20592; ASME. B-16.5a, ASME B16.25

Inspection and test shall be in accordance with JB / T 9092 and GB / t13927-1992 API598

Fire protection design according to api607;

The double eccentric hemispherical valve is the best equipment for conveying pulverized coal powder, control gas, granular fluid and solid medium with powder foam. It is a special valve for pulverized coal injection in metallurgy and mineral processing. This series of eccentric hemispherical valves are suitable for medium and low pressure pipeline systems in petroleum, chemical, metallurgy, electric power, light textile, papermaking, water conservancy and other departments, as well as for sewage treatment, steam, air, gas, sand slurry, pulp and other weakly turbid fluid medium transportation and interception, throttling, etc.

| name | texture of material |

| valve body |

QT450、WCB、ZG20CrMo、ZG1Cr18Ni9Ti |

| Valve shaft |

2Cr13、1Cr13 |

| Disc | Alloy nitriding steel, nitriding stainless steel, wear-resistant steel |

| valve seat | Alloy nitriding steel, nitriding stainless steel, wear-resistant steel |

| Bearing | Aluminum bronze, Fz-1 composite |

| filler | Polytetrafluoroethylene, flexible graphite |

|

Nominal pressure(Mpa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

|

Nominal diameter(mm) |

40-1600 |

40-1600 |

40-1200 |

40-600 |

40-600 |

|

Sealing test pressure(Mpa) |

0.66 |

1.1 |

1.76 |

2.75 |

4.4 |

|

Shell test pressure(Mpa) |

0.9 |

1.5 |

2.4 |

3.75 |

6.0 |

|

Applicable temperature(℃) |

-29~300、-29~425、-29~540 |

||||

| Applicable media | Water, sea water, sewage, acid and alkali liquid, slurry, steam, gas, oil | ||||

| Driving mode | Manual, electric, pneumatic | ||||

| Connection form | Flange connection, clamp connection | ||||

| Installation mode | Vertical installation, horizontal installation |

|

Nominal pressure PN/Mpa |

Nominal diameter |

size(mm) |

size(mm) |

||||||||||||||

|

|

|

L |

D |

K |

d |

f |

C |

Z-¢d |

H |

||||||||

|

1.6 |

40 |

165 |

150 |

110 |

85 |

3 |

16 |

4-¢18 |

|

||||||||

|

|

50 |

178 |

165 |

125 |

100 |

|

|

|

|

||||||||

|

|

65 |

190 |

185 |

145 |

120 |

|

18 |

|

280 |

||||||||

|

|

80 |

203 |

200 |

160 |

135 |

|

20 |

8-¢18 |

320 |

||||||||

|

|

100 |

229 |

220 |

180 |

155 |

|

|

|

370 |

||||||||

|

|

125 |

254 |

250 |

210 |

185 |

|

22 |

|

430 |

||||||||

|

|

150 |

267 |

285 |

240 |

210 |

|

24 |

8-¢23 |

510 |

||||||||

|

|

200 |

292 |

340 |

295 |

265 |

|

26 |

12¢-23 |

600 |

||||||||

|

|

250 |

330 |

405 |

355 |

320 |

|

30 |

12-¢26 |

690 |

||||||||

|

|

300 |

502 |

460 |

410 |

375 |

4 |

|

|

760 |

||||||||

|

|

350 |

572 |

520 |

470 |

435 |

|

34 |

16-¢26 |

830 |

||||||||

|

|

400 |

610 |

580 |

525 |

485 |

|

36 |

16-¢30 |

925 |

||||||||

|

|

450 |

660 |

640 |

585 |

545 |

|

40 |

20-¢30 |

1025

|

||||||||

|

|

450 |

660 |

|

|

|

|

|

|

1025 |

|

640 |

585 |

545 |

|

40 |

|

|

1120 |

||

|

715 |

650 |

608 |

|

44 |

20-¢34 |

|

|

1210 |

|

|

|

840 |

770 |

718 |

5 |

48 |

20-¢36 |

|

|

|

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website