Telephone:

0577-67975099

Location:Home > Product Center > control valve > Multifunctional Piston Control Valve

Location:Home > Product Center > control valve > Multifunctional Piston Control Valve

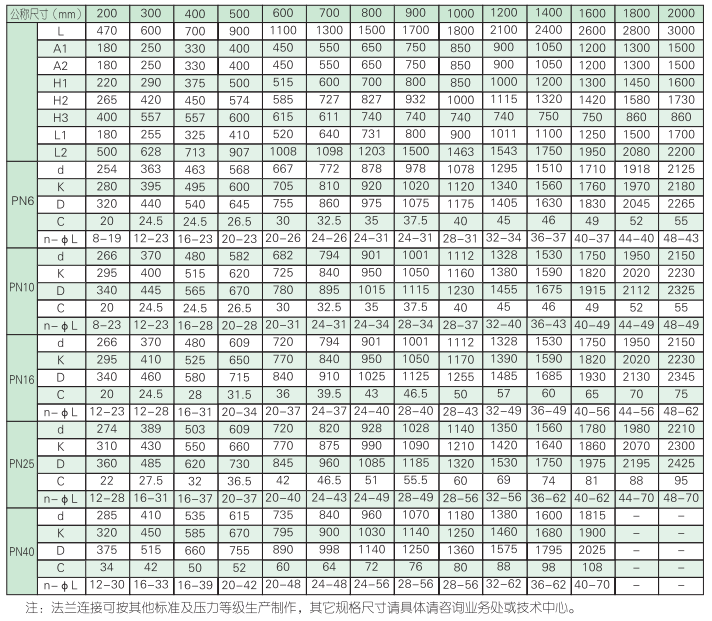

Introduction: as an improved product of needle valve, piston control has long been active in long-term water delivery, dams and hydropower stations. Piston control valve is a reasonable design, simple operation, low maintenance rate and economic and effective energy dissipation valve. It is also a flow and pressure regulating valve suitable for special working conditions. Models: ppah, ppeh, ppgh, ppph, pdax, PDEX, pdgx, pdpx Caliber: dn200-dn2000 Material: QT450 ductile iron, cast steel, stainless steel Driving mode: piston type and diaphragm type

As an improved product of needle valve, piston control valve has been active in long-term water delivery, dam and hydropower station. Piston control valve is a reasonable design, simple operation, low maintenance rate and economic and effective energy dissipation valve. It is also a flow and pressure regulating valve suitable for special working conditions.

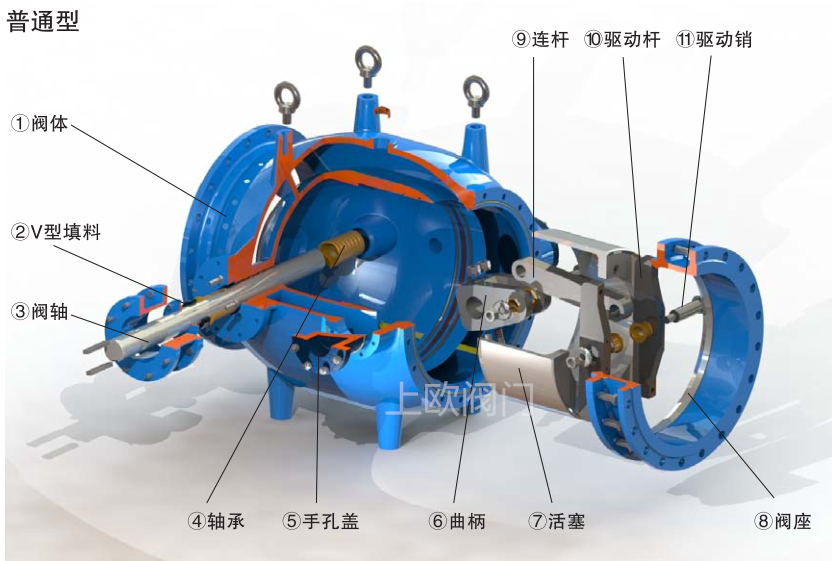

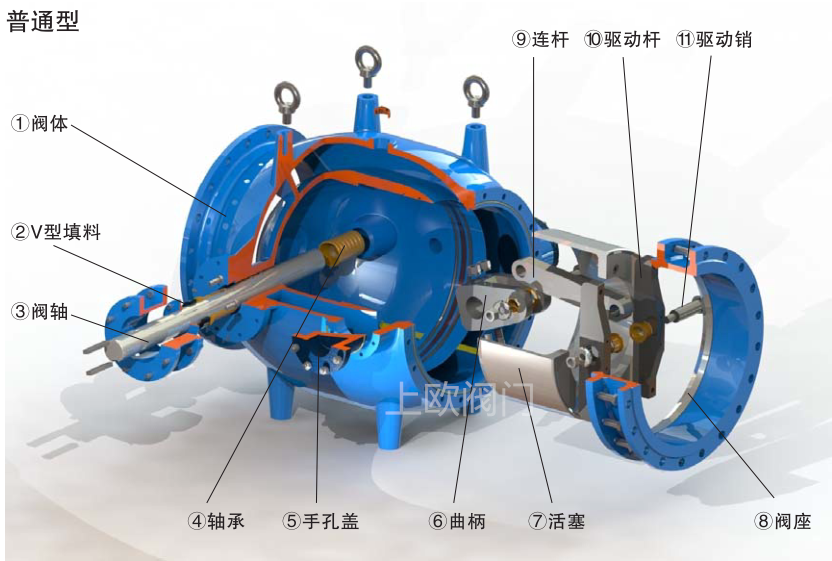

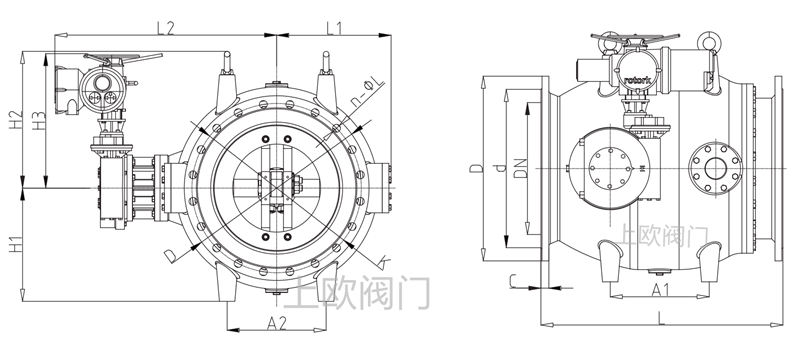

Piston control valve is mainly composed of valve body, valve seat, piston, valve shaft, crank, connecting rod, driving pin, taper pin, bearing and operating mechanism. The piston control valve transforms the rotation of the valve shaft into the axial movement of the piston along the guide rail through the crank connecting rod mechanism. In the process of the piston moving forward and backward, the flow regulation and pressure control are realized by changing the flow area between the piston and the valve seat.

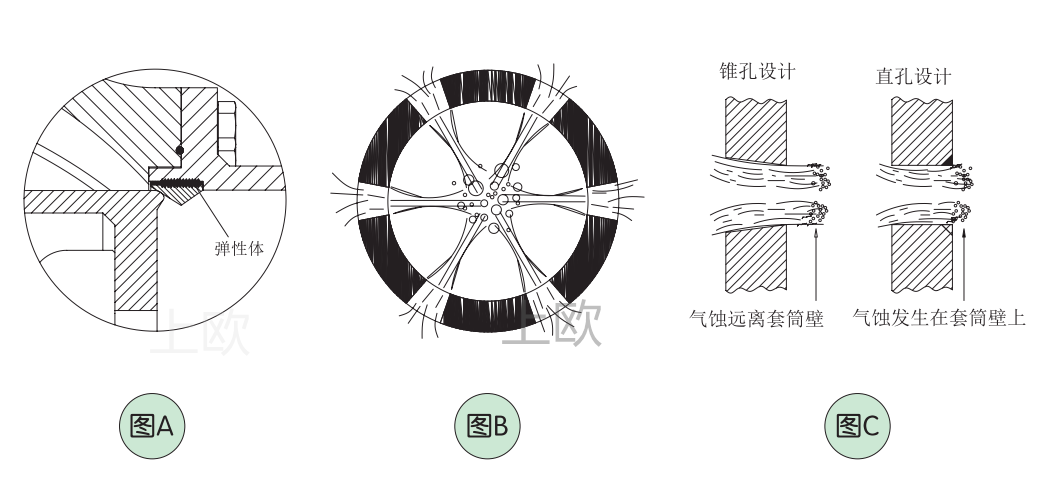

The water flows into the valve body from the axial arc, and the flow passage in the piston control valve is axisymmetric, and the fluid will not produce turbulence when it flows through. No matter where the piston moves to any position, the water flow section in the valve chamber is annular at any position, and it shrinks to the axis at the outlet, so as to prevent cavitation from damaging the valve body and pipeline caused by throttling.

Piston control valve is mainly composed of valve body, valve seat, piston, valve shaft, crank, connecting rod, driving pin, taper pin, bearing and operating mechanism. The piston control valve transforms the rotation of the valve shaft into the axial movement of the piston along the guide rail through the crank connecting rod mechanism. In the process of the piston moving forward and backward, the flow regulation and pressure control are realized by changing the flow area between the piston and the valve seat.

The water flows into the valve body from the axial arc, and the flow passage in the piston control valve is axisymmetric, and the fluid will not produce turbulence when it flows through. No matter where the piston moves to any position, the water flow section in the valve chamber is annular at any position, and it shrinks to the axis at the outlet, so as to prevent cavitation from damaging the valve body and pipeline caused by throttling.

Material list of each component

| Serial number | 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

| name | valve body |

VV-packing |

Valve shaft | Bearing | Handcap hole | crank | piston | valve seat | connecting rod | Driving lever | Drive pin | Backwash sleeve (optional) |

| Ductile iron / cast steel | Butadiene rubber |

SUS304 |

copper alloy |

QT450/WCB |

SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

The common piston control valve is used in the condition of small pressure difference and medium containing suspended solids. The ordinary water flows into the shell from the axial arc, and contracts to the axis at the outlet. The cavitation bubbles caused by collision are limited in the center of the pipe and are completely surrounded by water. Even if these bubbles break due to instability, they are in the center of the pipe and not on the wall of the pipe and valve. Therefore, there is no cavitation fracture.

Because of the high pressure difference and high control precision, the multi orifice piston control valve is used. The spray holes on the multi orifice valve seat are designed according to the specific working conditions. The small holes are symmetrically distributed on the wall of the valve seat, and the water flow collides with the center line of the valve through the small holes. In the turbulent area with small stroke in the center of the valve seat, the violent collision and friction inside the water eliminated most of the capacity.

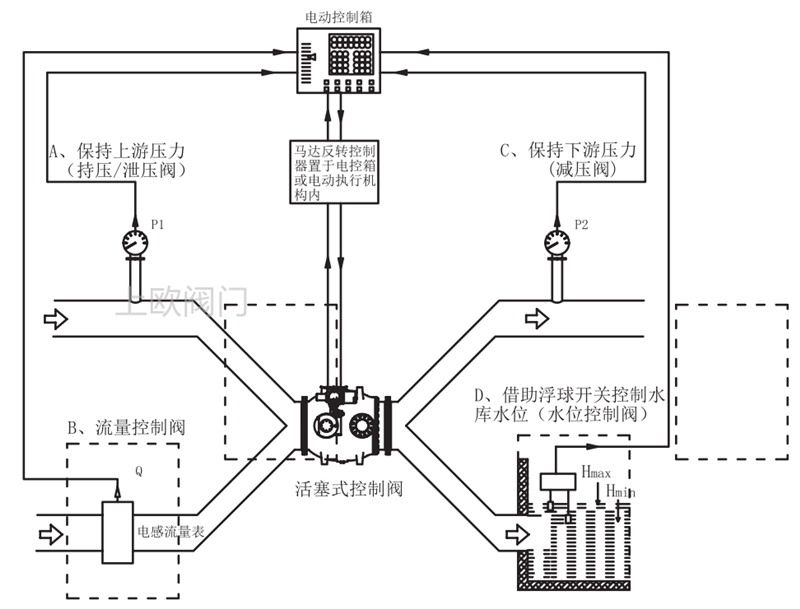

1、 Four control modes

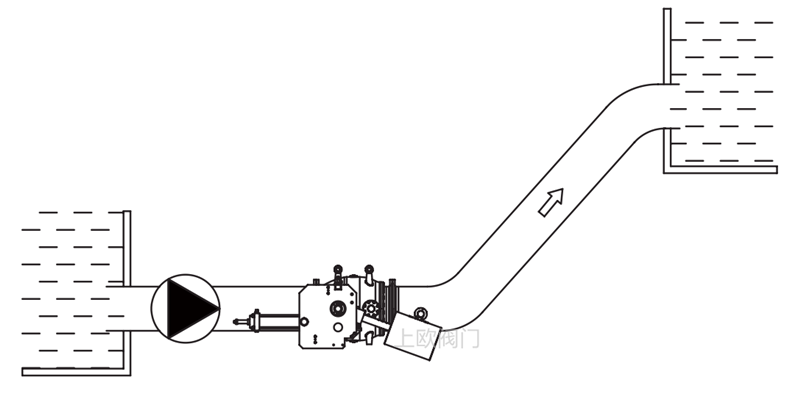

2、 Control valve for pump outlet. Open type slow opening: fast closing 90% and then closing slowly. The head loss is very small.

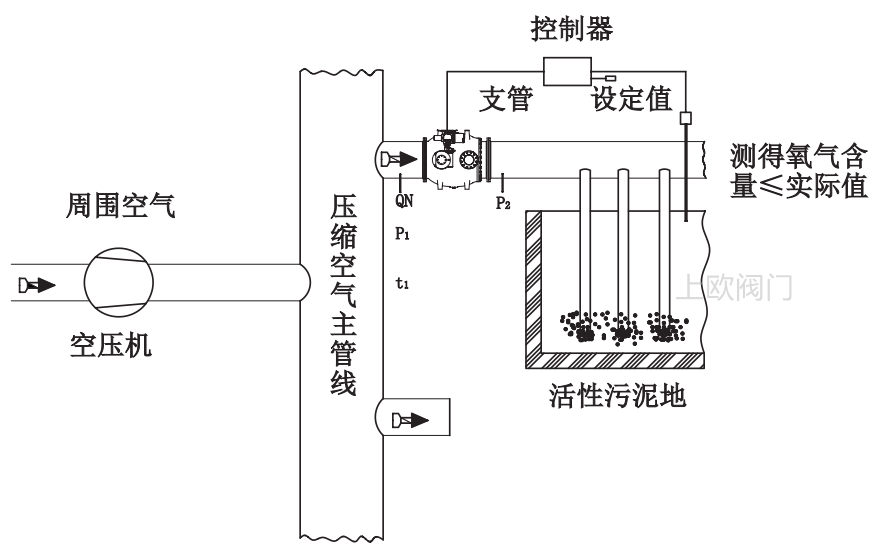

3、 Air flow control in aeration pipeline of activated sludge tank in sewage treatment plant

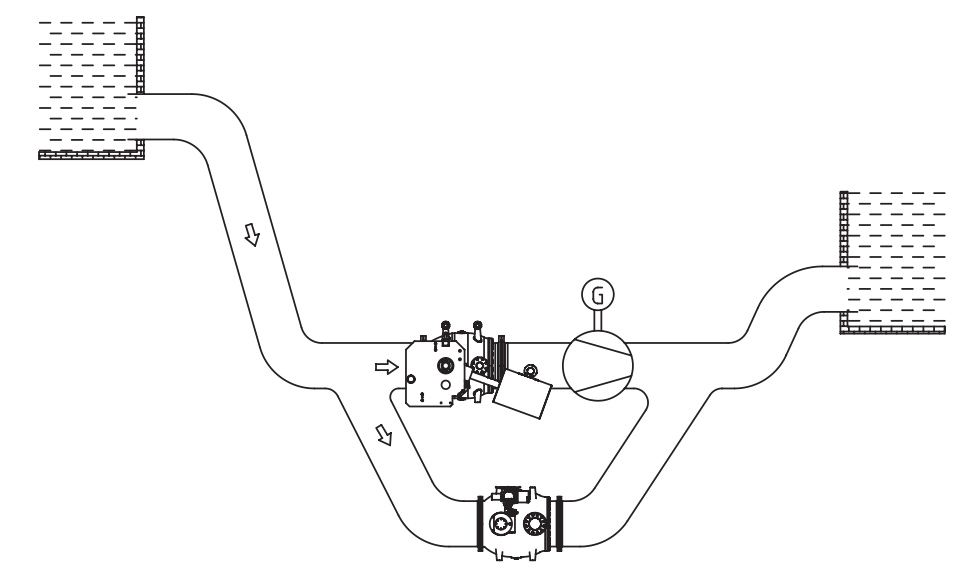

4: It is used for inlet opening and closing and bypass control of hydraulic turbine

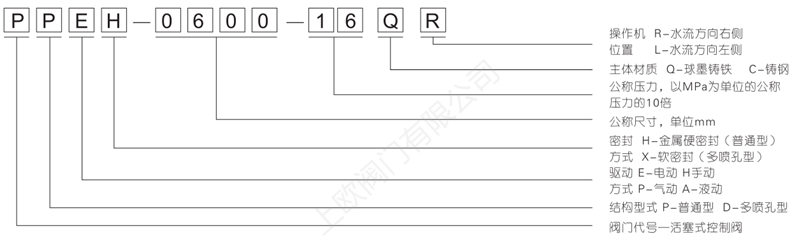

Example: ppeh-1000-16qr means that the nominal size is DN 1000, the nominal pressure is 1.6Mpa, the main material is ductile iron, and the ordinary electric piston control valve is installed on the right side of the water flow direction

自动水力控制阀进出口压力推荐及防.....

Maintenance Manu.....

V-type ball valve is a kind of.....蝶阀常见的试验和安装及故障排除方.....

1、本产品无论是手动、气动、液动、电动各部件在出厂前均经严.....管力阀八大技术特点分析

管力阀八大技术特点分析旋球阀产品概述

旋球阀结合球阀的优越密 封性能与蝶阀的优势结构性能研发而成,.....常用球阀等产品所执行的国家标准解.....

《通用阀门法兰和对焊连接钢制球阀》GB/T12237-89 .....管力阀是一种什么样的阀门

管力阀是我公司历时五年研发的zui新水泵出口控制阀,是继老.....调流调压阀焊接技术要求

调流调压阀是一种多功能活塞式调节阀、该产品有活塞式、套筒式、.....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website