Telephone:

0577-67975099

Location:Home > Product Center > control valve > Eccentric plug valve with elastic seat seal

Location:Home > Product Center > control valve > Eccentric plug valve with elastic seat seal

The elastic seat seal structure of the eccentric plug valve with elastic seat seal overcomes the defects of poor sealing performance and easy corrosion of the traditional plug code. The unique eccentric seal design greatly reduces the operating torque compared with the traditional plug valve, and Zui greatly reduces the wear of the sealing surface and prolongs the service life of the valve. The rectangular straight channel has small head loss and good flow regulation linearity. It has excellent sealing and corrosion resistance, ideal operation performance and long service life. It is suitable for urban sewage, industrial sewage, mud and clean water and other working environment as a closure or regulation device.

Our company's new type of eccentric valve is designed and manufactured by our company.

The elastic sealing structure of the valve overcomes the defects of poor sealing performance and easy corrosion of the traditional cock code. The unique eccentric seal design greatly reduces the operating torque compared with the traditional plug valve, and Zui greatly reduces the wear of the sealing surface and prolongs the service life of the valve. The rectangular straight channel has small head loss and good flow regulation linearity. It has excellent sealing and corrosion resistance, ideal operation performance and long service life. It is suitable for urban sewage, industrial sewage, mud and clean water and other working environment as a closure or regulation device.

| Eccentric seal design There is an eccentricity between the valve sealing surface center and the cock rotating shaft. Using the principle of eccentric movement, the closer the cock and the valve seat are, the closer the valve is sealed; when the valve is opened, the cock and the valve seat can be separated quickly without contact wear, and the valve has a long service life. |

阀体剖面图

|

| Integral rubber covered cock Nodular cast iron cock frame is coated with high-performance rubber, which has good sealing elasticity, and has no worries of rubber falling off and erosion corrosion. |

|

| Special corrosion resistant valve seat According to the different working medium, the valve seat can be made of pure nickel, stainless steel or other special materials, and the valve body is compounded with new surface treatment technology. The combination is firm and can resist erosion and corrosion of various media. |

|

| Rectangular straight channel Through flow channel makes the head loss of valve very small; the flow section of valve seat is rectangular, which can obtain linear adjustment of flow rate; the larger geometric size of rectangle and the self flushing design of flow channel are more suitable for sewage or occasions containing solid impurities. |

|

| Integrated bow valve shaft The valve shaft and plug are integrally cast into shape, with high strength and load transmission rigidity, thus eliminating the danger of failure of the traditional plug valve shaft pin. Compared with the traditional plunger, the arcuate cock can reduce the weight by nearly half, avoid the flow channel when the valve is fully open and has the function of guiding. |

|

| Light and compact structure The valve body is made of high strength ductile iron, and the weight is reduced by more than 20% compared with the traditional plug valve. The short distance between the valve faces shortens the residence time of the fluid in the flow passage, and the increase of the fluid velocity reduces the deposition of impurities. |

|

| Corrosion resistant surface treatment The inner and outer surface of the valve is sprayed with non-toxic epoxy resin to prevent the valve body from rusting. It is suitable for sewage system, outdoor and underground environment. |

| Part number | name | texture of material |

|

1 |

valve body | Ductile iron |

|

2 |

Cock | Nodular cast iron coated with NBR or EPDM |

|

3 |

valve seat | Pure nickel, stainless steel or special materials |

|

4 |

O-ring |

NBR |

|

5 |

Bearing | Bronze or Brass |

|

6 |

Valve cover | Ductile iron |

|

7 |

V-ring |

NBR |

|

8 |

Gland | Ductile iron |

|

|

|

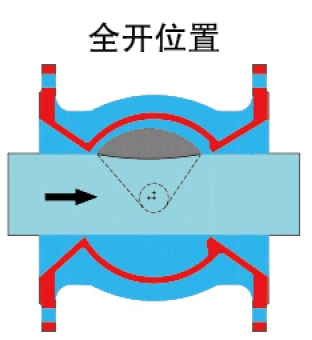

| Full open position Straight flow channel, self flushing design, not easy to accumulate impurities. The shape of the eight mouth spines was restored to the ideal shape. |

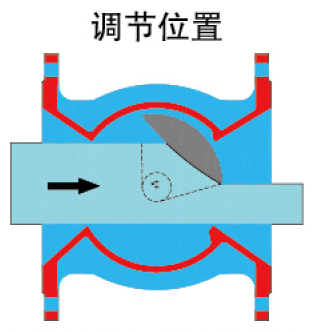

Adjust the position The valve can adjust the flow rate at any opening, the cock diversion effect is obvious, and the flow regulation linearity is good. During adjustment, there is no contact wear between the cock and the valve seat. |

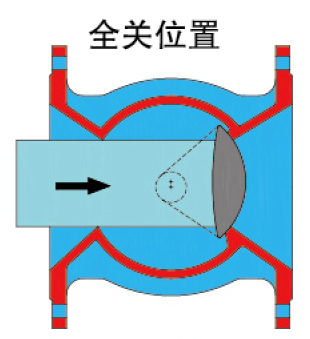

Fully closed position The higher the pressure, the better the sealing performance. The more eccentric movement, the closer the cock and valve seat are. The forward seal is completely zero leakage. |

| Technical characteristics | characteristic parameter | |

|

characteristic parameter(℃) |

0~65℃ |

|

|

Nominal sizeDN(mm |

50~900 |

|

|

Nominal pressurePN(mm) |

1.0 |

1.6 |

|

Strength test pressure(MPa |

1.5 |

2.4 |

|

Strength test pressure(MPa |

1.1 |

1.76 |

| Suitable working medium |

Sewage, raw water, clean water, oil(NBR) |

|

| Suitable working medium | ||

|

|

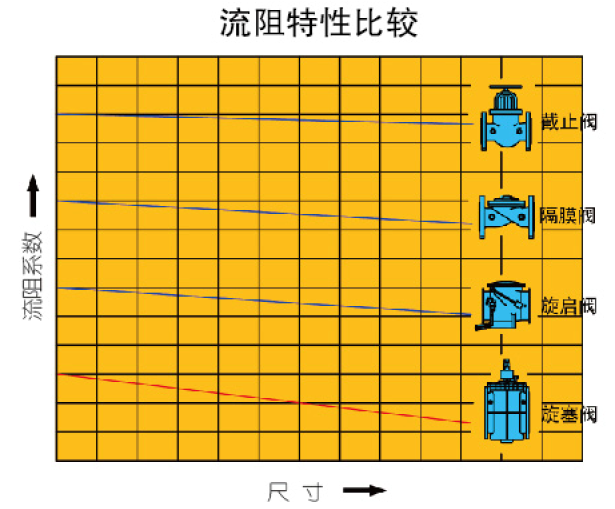

| Comparison of flow resistance characteristics At the same flow rate, the pressure loss and energy consumption of the plug valve are small, and with the increase of valve size, this advantage is more obvious. |

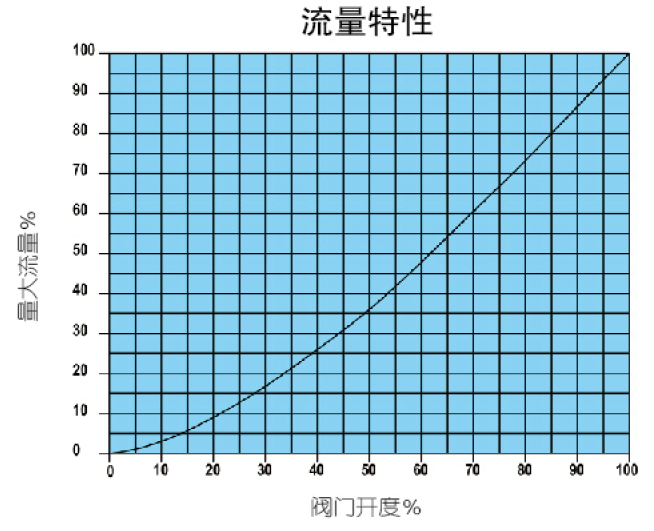

Flow characteristics When used as a control valve, the valve opening percentage has a linear relationship with Zui large flow percentage, and the valve flow can be controlled according to the opening indicator. |

|

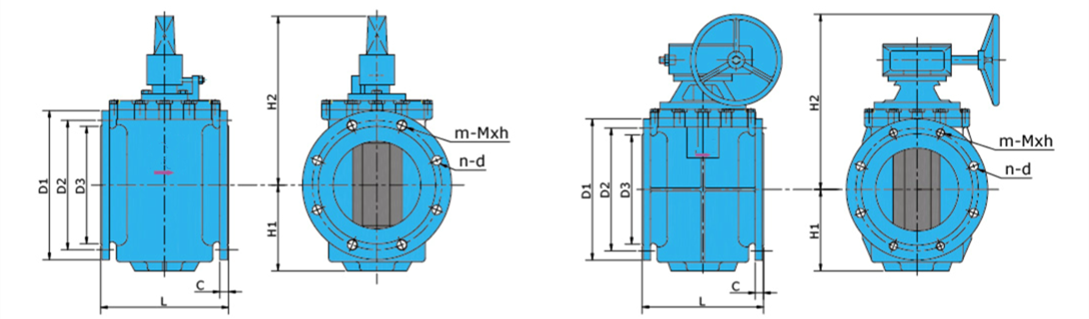

DN |

D1 |

D2 |

D3 |

C |

n-d |

m-Mxh |

L |

H1 |

H2 |

||||||||||

|

PN10 |

PN16 |

PN10 |

PN16 |

PN10 |

PN16 |

PN10 |

PN16 |

PN10 |

PN16 |

PN10 |

PN16 |

178 |

84 |

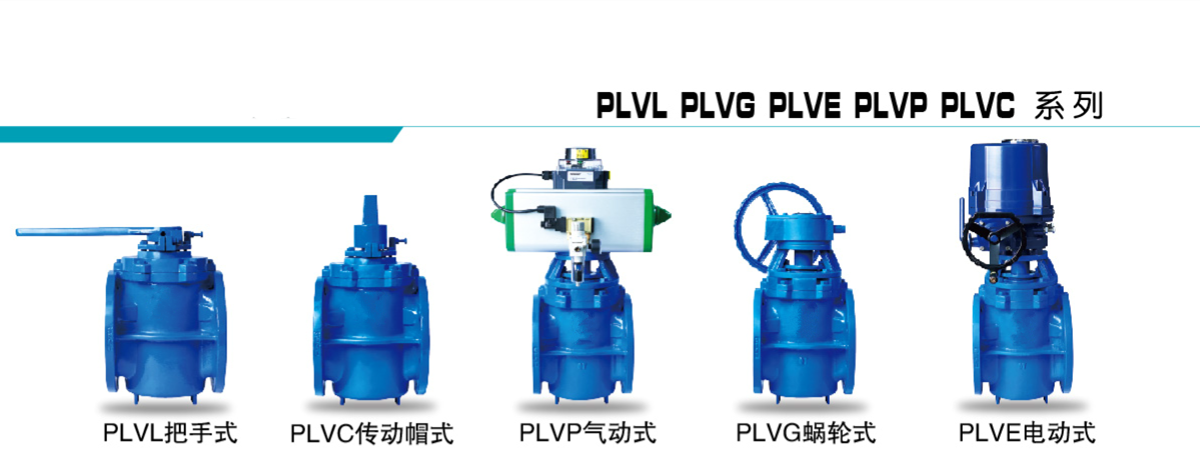

PLVL型 |

PLVC型 |

PLVG型 |

PLVE型 |

PLVP型 |

|

|

50 |

165 |

125 |

99 |

19 |

4-φ19 |

— |

190 |

93 |

143 |

225 |

265 |

315 |

265 |

||||||

|

65 |

185 |

145 |

118 |

19 |

4-φ19 |

— |

203 |

109 |

143 |

225 |

265 |

315 |

265 |

||||||

|

80 |

200 |

160 |

132 |

19 |

4-φ19 |

4—M16通孔 |

229 |

128 |

174 |

225 |

312 |

373 |

340 |

||||||

|

100 |

220 |

180 |

156 |

19 |

8-φ19 |

— |

229 |

128 |

174 |

225 |

312 |

373 |

340 |

||||||

|

125 |

250 |

210 |

184 |

19 |

8-φ19 |

— |

267 |

165 |

174 |

225 |

312 |

373 |

340 |

||||||

|

150 |

285 |

240 |

211 |

21 |

4-φ23 |

4—M16通孔 |

292 |

198 |

— |

340 |

444 |

481 |

488 |

||||||

|

200 |

340 |

295 |

266 |

21 |

4-φ23 |

8-φ23 |

4-M20通孔 |

4-M20深25 |

330 |

249 |

— |

— |

464 |

508 |

558 |

||||

|

250 |

395 |

405 |

350 |

355 |

319 |

24 |

8-φ23 |

8-φ28 |

4-M20深30 |

4-M24深35 |

356 |

290 |

— |

— |

527 |

630 |

729 |

||

|

300 |

445 |

460 |

400 |

400 |

370 |

25 |

8-φ23 |

8-φ28 |

4-M20深30 |

4-M24深35 |

432 |

330 |

— |

— |

710 |

666 |

729 |

||

|

350 |

505 |

520 |

460 |

470 |

429 |

26 |

26.5 |

8-φ23 |

8-φ28 |

4-M20深30 |

4-M24深35 |

450 |

355 |

— |

— |

723 |

767 |

— |

|

|

400 |

565 |

580 |

515 |

525 |

480 |

28 |

8-φ23 |

8-φ31 |

8-M24深36 |

4-M27深40 |

450 |

355 |

— |

— |

749 |

881 |

— |

||

|

450 |

615 |

— |

565 |

— |

530 |

— |

28 |

— |

12-φ28 |

— |

8-M24深36 |

— |

450 |

355 |

— |

— |

749 |

881 |

— |

|

500 |

670 |

— |

620 |

— |

582 |

— |

29 |

— |

12-φ28 |

— |

8-M24深36 |

— |

660 |

427 |

— |

— |

903 |

1015 |

— |

|

600 |

780 |

— |

725 |

— |

682 |

— |

30 |

— |

12-φ31 |

— |

8-M27深40 |

— |

762 |

567 |

— |

— |

1015 |

1202 |

— |

|

700 |

895 |

— |

840 |

— |

794 |

— |

32.5 |

— |

16-φ31 |

— |

8-M27深40 |

— |

865 |

633 |

— |

— |

1393 |

1351 |

— |

|

800 |

1015 |

— |

950 |

— |

901 |

— |

35 |

— |

16-φ34 |

— |

8-M30深45 |

— |

965 |

633 |

— |

— |

1393 |

1351 |

— |

|

900 |

1115 |

— |

1050 |

— |

1001 |

— |

37.5 |

— |

28-φ34 |

— |

— |

— |

1424 |

860 |

— |

— |

1902 |

1892 |

— |

remarks:

1. Flange connection dimension shall be made according to PN10 / 16 of GB / t17241.6-1998 standard

2. Manufacture of series 3 of structural length L parameter gb-12221-89

3. The operating height of the valve varies with the selection of different operators. The worm wheel type operation hand wheel can be replaced by a driving cap;

4. The above are our standard products. If you have special requirements, please contact the business department or agent;

自动水力控制阀进出口压力推荐及防.....

Maintenance Manu.....

V-type ball valve is a kind of.....蝶阀常见的试验和安装及故障排除方.....

1、本产品无论是手动、气动、液动、电动各部件在出厂前均经严.....管力阀八大技术特点分析

管力阀八大技术特点分析旋球阀产品概述

旋球阀结合球阀的优越密 封性能与蝶阀的优势结构性能研发而成,.....常用球阀等产品所执行的国家标准解.....

《通用阀门法兰和对焊连接钢制球阀》GB/T12237-89 .....管力阀是一种什么样的阀门

管力阀是我公司历时五年研发的zui新水泵出口控制阀,是继老.....调流调压阀焊接技术要求

调流调压阀是一种多功能活塞式调节阀、该产品有活塞式、套筒式、.....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website