Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > DYQ340HManual top mounted eccentric hemisphere valve

Location:Home > Product Center > Ball Valve > DYQ340HManual top mounted eccentric hemisphere valve

DYQ340HManual top mounted eccentric hemispherical valve is a new product successfully developed by absorbing and digesting the advanced technology at home and abroad. It fixes the metal ball crown on the eccentric ball, realizes the valve opening and closing by 90 degrees rotation of the eccentric crankshaft, and the metal valve seat contacting with the sealing surface of the metal ball crown floats in axial and radial directions to compensate for the matching between the ball crown and the valve seat. The valve is used in petroleum, chemical, electric power and metallurgy industries. The valve structure adopts the principle of eccentric wedge tightening...........

DYQ340HManual top mounted eccentric hemispherical valve is a new product successfully developed by absorbing and digesting the advanced technology at home and abroad. It fixes the metal ball crown on the eccentric ball, realizes the valve opening and closing by 90 degrees rotation of the eccentric crankshaft, and the metal valve seat contacting with the sealing surface of the metal ball crown floats in axial and radial directions to compensate for the matching between the ball crown and the valve seat. The valve is used in petroleum, chemical, electric power and metallurgy industries. The valve structure adopts the eccentric wedge tight principle. The purpose of opening, adjusting and closing is achieved through the transmission mechanism. The sealing ring and spherical crown are metal surface ring with hard surface contact seal. When the double eccentric structure valve is opened, the ball body is hidden in the valve cavity, and the flow section is large, and the valve is not scoured and has no flow resistance. When closing, the valve core will not be scoured. When closing, the spherical surface of the valve core will gradually move along the valve seat, with shear function, which can effectively remove the scaling obstacles, and now it is reliably sealed. It is especially effective for the transportation of medium easy to scale. The valve hemisphere is to fix the metal ball crown on the eccentric ball, and install different alloy ball crowns on the ball. The valve seat is also made of corresponding hardfacing alloy. After special treatment, the sealing surface is composed of various types, such as anti-corrosion, wear-resistant and high-temperature resistance, to meet the needs of different occasions. The valve seat and the ball crown have compensation. When the valve seat is worn, it can still be reliably sealed and the service life can be prolonged. This valve's Zui big characteristic is in the working condition installment.

1. It is suitable for water, raw water (including mud sand), sewage, sea water, steam water, oil, alumina, urban heating and heating system with strict requirements.

2. It is suitable for the temperature from - 40 ℃ to 600 ℃ for the eccentric hemisphere valve.

3. It is suitable for the vent valve and control valve at the bottom of the dam (high flow rate state), pulverized coal ash and slag. It is suitable for industrial pipeline transportation of liquid, solid two-phase mixed flow or chemical reaction with crystallization precipitation or scaling in liquid transportation. According to the different media and temperature requirements of customers, the ball crown adopts chromium molybdenum and vanadium alloy, and the valve seat is overlaid with chromium, molybdenum, chromium alloy and stainless steel alloy to meet the needs of different slurry transportation.

4. Suitable for pump delivery system valves, such as pressurization system, central air conditioning system.

1. Small pressure loss: when the valve is fully opened, the water loss is zero and the flow channel is completely unblocked; the inner cavity is automatically cleaned, and the valve core rotates 90 degrees to automatically flush the inner cavity of the valve body, and the impurities in the medium are cleaned and the medium will not deposit in the valve chamber. The ball is hemispherical in shape and has a high CV value of Zui, which enhances the system efficiency of the pump and reduces the abrasion to a low degree of Zui.

2. Wear resistance: using the principle of double eccentricity, in the process of closing, the ball crown is close to the valve seat only at the moment after Zui, without forming friction; and the sealing ring on the valve seat is overlaid with wear-resistant self-lubricating alloy, which is not easy to wear and wash; the ball crown and valve seat of knife shaped ball have the function of cleaning and shearing, so it is not easy to scale.

3. The automatic compensation seal is reliable: under positive pressure, using the principle of eccentricity, the closer the ball and the valve seat are, the better the sealing can be obtained; under the back pressure, the floating valve seat will automatically push the valve seat to the ball, and the higher the pressure, the more tightly the valve seat will push to the ball, so as to get a good seal; it can keep a long-lasting tight seal and adapt to harsh working conditions. In the long-term use, if the valve seat seal is worn or damaged, the valve seat will automatically push to the ball under the action of spring, so as to get good automatic compensation function.

4. Suitable for high velocity media: because the ball is hidden in the valve chamber_ The solid eccentric fixed crankshaft has no vibration and noise in high velocity medium.

5. Long service life, easy to switch: no vulnerable parts, due to the role of eccentricity, the sealing surface of the ball and the valve seat is completely separated during the opening and closing process of the valve, so that there is no scratch between the valve seat surface and the spherical surface of the ball crown. The operation torque is effectively reduced, and the operation is light and convenient. The automatic compensation function of the valve greatly improves the service life of the valve.

6. Convenient maintenance: the valve is of top mounted design, and the ball crown and branch ball are installed from the upper part of the valve; during maintenance, it is only necessary to open the valve cover and lift out the ball crown and branch ball to carry out maintenance and sealing ring and other accessories, and it is unnecessary to unload the whole valve from the pipeline, which brings great convenience to underground pipelines, especially ball valves for atomic energy industry.

7. The valve can reserve the medium in the pipeline at the same time of maintenance, which will not cause waste of energy; this will eliminate the user's many early auxiliary work, making the maintenance more simple. 8. In some special occasions, the valve can not affect the normal operation of the pipeline system during rush repair, as long as the ball assembly is quickly closed, the pipe can be restored immediately

|

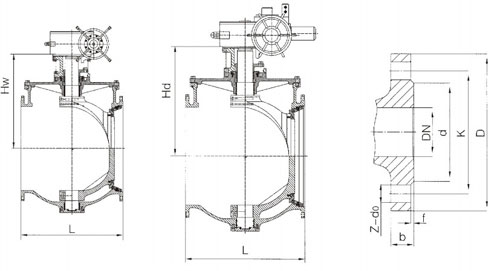

DYQ340HMain dimensions of manual top mounted eccentric hemisphere valve(mm) |

||||||||||

| Nominal pressure | Nominal diameter |

size(mm) |

||||||||

|

|

|

L |

D |

K |

d |

b |

f |

Z-do |

Hw |

Hd |

|

Flange standard |

DN100 |

229 |

220 |

180 |

156 |

22 |

2 |

8-φ18 |

330 |

380 |

|

|

DN125 |

254 |

250 |

210 |

184 |

22 |

2 |

8-φ18 |

345 |

405 |

All the text, data and pictures in this paper are for reference only. For details of performance parameters, structural dimension parameters and price of dyq340h manual top mounted eccentric hemisphere valve, please contact us at

Shanghai Europe valve service commitment:

(1) In strict accordance with the requirements of the contract, to provide qualified products that meet the design standards.

(2) Strictly check and control the quality of raw materials, components and accessories.

(3) Ensure that the processing technology of the equipment is perfect and the detection means are complete. Products will never leave the factory with defects.

(4) Be fully responsible for the supply, quality, equipment performance, technical interface, service and other aspects of the subcontractor. The key parts specified in the contract must meet the requirements of relevant qualification and be approved by the demander.

(5) Provide relevant department standards and drawings to the supervision unit according to the contract, provide convenience for the supervision, and inform the demander and the supervision representative of the shutdown parts of the supervision equipment 7 days in advance. The supervision assigned by the demander is to urge us to produce qualified products according to the standards, but it does not reduce all our quality responsibilities.

(6) The quality defects in the process of equipment manufacturing shall be timely reported to the demander and the supervision representative without concealment. If the equipment defect exceeds the standard specified in the contract, the supplier shall replace it unconditionally. In the process of installation and trial operation, if there are quality problems of the equipment, the problems should be dealt with first, and then the responsibilities should be clarified. Everything should be based on the requirements of project progress.

(7) In case of any accident, we will replace and repair the supplied equipment free of charge as soon as possible until the demander is satisfied.

(8) In case of missing parts or missing parts caused by other reasons in the process of unpacking, we are responsible for making up the missing parts for free as soon as possible. We shall be responsible for the quality problems found during the installation and commissioning of the equipment and in the operation of the equipment in the future.

(9) Provide the demander with all technical data and drawings according to the contract on time. Have the obligation to invite the demander to participate in our technical design audit when necessary.

(10) According to the time required by the demander to the site for technical services, guide the demander to install, trial run and trial production according to the requirements of our technical data and drawings.

(11) For the supporting equipment related to the contract equipment purchased by the demander first, we will actively provide the technical conditions and data meeting the equipment interface requirements.

(12) Strictly implement the minutes or agreements of the meeting held by both parties on relevant issues.

(13) According to the provisions of the contract, free business training courses on equipment installation, commissioning, use and maintenance technology shall be held for the demander.

(14) Strengthen pre-sale, in-sales and after-sales services, and implement "24-hour service", "advanced service", "whole process service" and "life-long service" in the whole process of product manufacturing, installation, commissioning and overhaul.

(15) After receiving the quality problem information reflected by the demander, reply within 24 hours or send service personnel to the site as soon as possible, so as to ensure that the user is not satisfied with the quality and the service does not stop.

(16) Free for the product to provide lifelong maintenance, where our factory users, have established a detailed user file, our factory after-sales service. Regular return visit and inspection system are implemented to guide the daily maintenance of users, and timely point out and solve possible faults.

(17) At any time to meet the demander's requirements for spare parts, lifetime to provide users with high-quality and low-cost spare parts.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website