Telephone:

0577-67975099

Location:Home > Product Center > control valve > GWXDF Two way hard seal ball valve

Location:Home > Product Center > control valve > GWXDF Two way hard seal ball valve

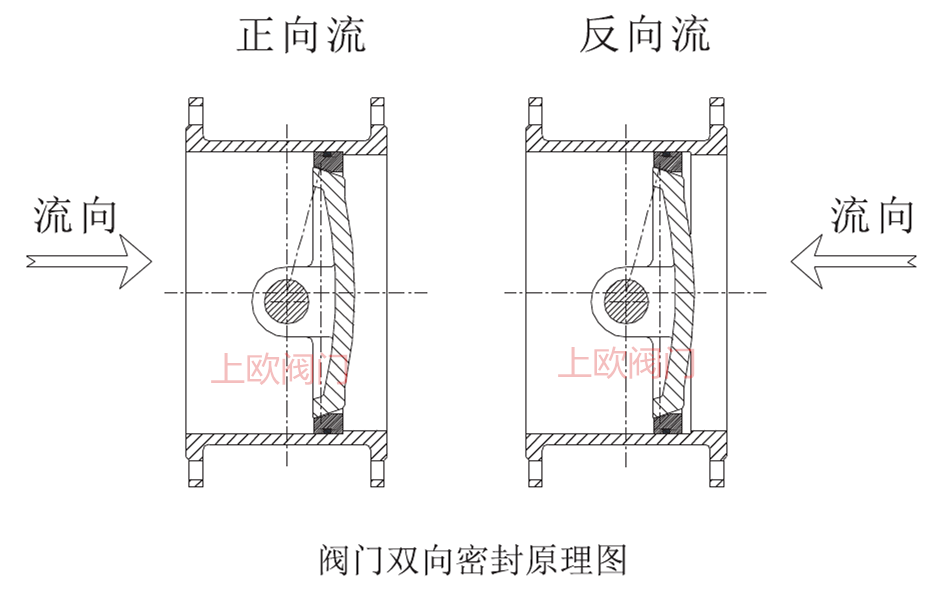

Gwxdf9 / 6 / 3204h electric bidirectional pressure hard impact hard ball valve can not only be reliably cut off under positive pressure, but also can be reliably sealed when reverse pressure or reverse pressure is much greater than forward pressure. The valve seal adopts the structure and principle of hemispherical valve, and the shape adopts butterfly structure, so it has the characteristics of small volume and light weight, and has the performance of two-way hard seal, small sealing friction, durable and light opening and closing. Therefore, the cost performance ratio is far higher than that of hemispherical valve. The successful development and application of the valve is a major technical improvement in the valve industry. It is widely used in pump outlet, pipe network system, water recovery system, high level water tank, easily flooded sewage system, anti backflow system and other occasions requiring two-way sealing. It can be used in metallurgy, mining, petrochemical, chemical, electric power, environmental protection, municipal and other industries as pipeline opening and closing and adjusting. In the two-way flow system, one valve is equivalent to two ordinary one-way sealing valves.

Zxqf9247hr electric bidirectional pressure hard impact hard ball valve can not only be reliably cut off under positive pressure, but also can be reliably sealed when the reverse pressure or reverse pressure is far greater than the forward pressure. The valve seal adopts the structure and principle of hemispherical valve, and the shape adopts butterfly structure, so it has the characteristics of small volume and light weight, and has the performance of two-way hard seal, small sealing friction, durable and light opening and closing. Therefore, the cost performance ratio is far higher than that of hemispherical valve. The successful development and application of the valve is a major technical improvement in the valve industry. It is widely used in pump outlet, pipe network system, water recovery system, high level water tank, easily flooded sewage system, anti backflow system and other occasions that need two-way sealing. It can be used in metallurgy, mining, chemical, chemical, electric power, environmental protection, municipal and other industries as pipeline opening and closing and regulating. In the two-way flow system, one valve is equivalent to two ordinary one-way sealing valves.

Two way hard seal ball valve is widely used in pump outlet, pipe network system, especially municipal, fire control and other network, annular pipe network. In this kind of two-way flow condition, one valve is equivalent to two ordinary one-way sealing valves, with high cost performance. It can be used to open, close and adjust the medium of pipe network system in metallurgy, petrochemical, electric power, chemical industry, environmental protection, municipal and other industries and departments.

Driving mode:

| Code name |

3 |

6 |

7 |

9 |

| Driving mode | Worm gear | Pneumatic | Hydrodynamics | Electric |

密封面材料:

|

H |

R |

Y |

||

| Sealing surface material | Martensite does not induce steel | austenitic stainless steel |

Cemented carbide |

公称压力:

| Code name |

6 |

10 |

16 |

25 |

40 |

63 |

|

Nominal pressure(Mpa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

6.3 |

壳体材料:

| Code name |

C |

P |

R |

| Material Science |

WCB |

lCrl8Ni9Ti ZGlCrl8Ni9Ti |

lCrl8Nil2MoTi、 ZGlCrl8Nil2MoTi |

The latest version of undated reference documents is applicable to this product.

|

r"Standard content |

Standard number | Standard name |

| Enterprise standard |

Q/OPJF006-2012 |

Gwxdf two way flow hard seal ball valve |

| Design and manufacture standard |

CJ/T283-2008 |

Eccentric hemisphere valve of Urban Construction Department |

|

GB/T12237 |

General purpose valves - Flanged and butt welded steel ball valves | |

|

GB/T12238 |

General purpose valves - Flanged and wafer butterfly valves | |

| Structural length standard |

GB/T12221 |

Metal valve structure length |

| Flange standard |

GB/T9113.1-4 |

Integral steel pipe flange / customer specified standard |

| Integral cast iron pipe flange | ||

| Inspection and test standards |

GB/T13927 |

Pressure test for general purpose valves |

|

JB/T9092 |

Pressure test for general purpose valves | |

| Inspection and test standards |

GB/T12227 |

Technical conditions of ductile iron castings for general purpose valves |

| Technical specification of carbon steel castings for general purpose valves | ||

|

GB/T12230 |

Technical requirements of austenitic steel castings for general purpose valves |

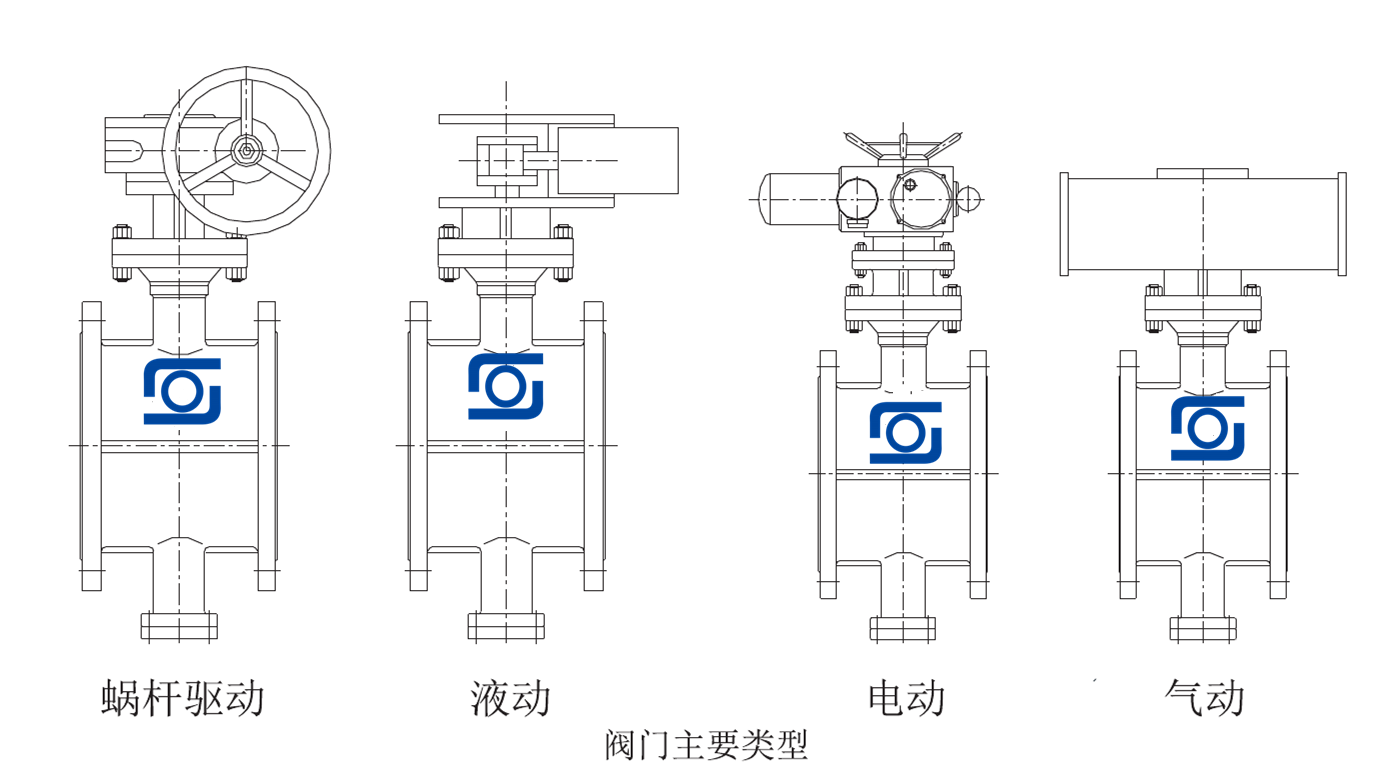

1、Main types: the main types of the valve are worm gear, electric, pneumatic and hydraulic, among which pneumatic valve and hydraulic valve are suitable for occasions with pressure gas source and pressure liquid source.

| Driving mode | worm drive | Hydrodynamics | Electric | Pneumatic |

| Flange model |

GWXDF3204 |

GWXDF7204 |

GWXDF9204 |

GWXDF6204 |

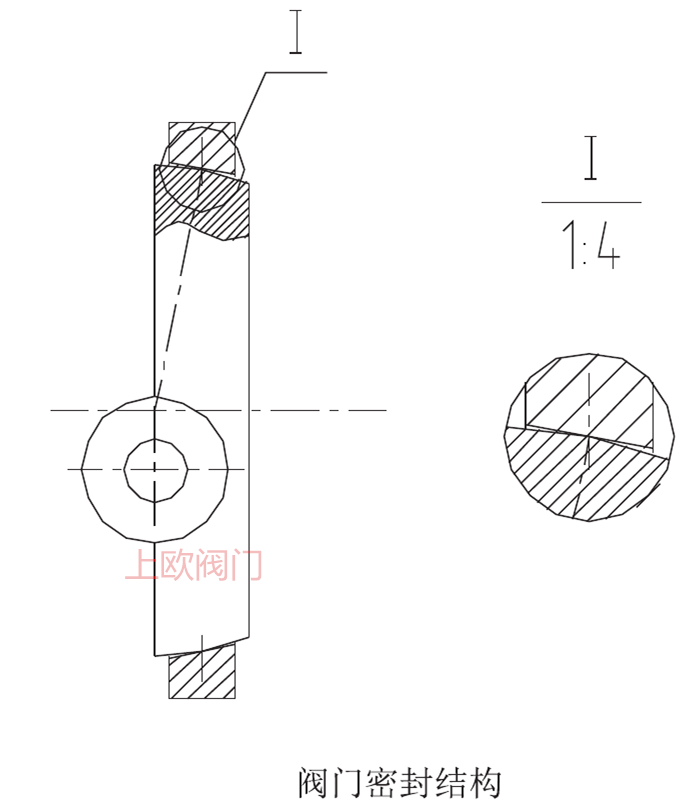

Working principle: the sealing surface of the valve core is cubic curved surface, and the sealing surface of the valve seat is a conical surface. At the sealing point, the seat surface is actually the section of the valve core cubic curved surface (see Figure), so its combination is perfect. It has the function of self-adaptive (center automatic positioning and reclosing) and wear compensation.

Because the rotation center deviates from the geometric center of the valve core, there will be the actual effect of the valve core body constantly moving backward and inward when the valve core is opened, and the valve core body is constantly moving forward and expanding outward when the valve core is closed. Its function is equivalent to the synthesis of hemispherical valve, gate valve, globe valve and butterfly valve.

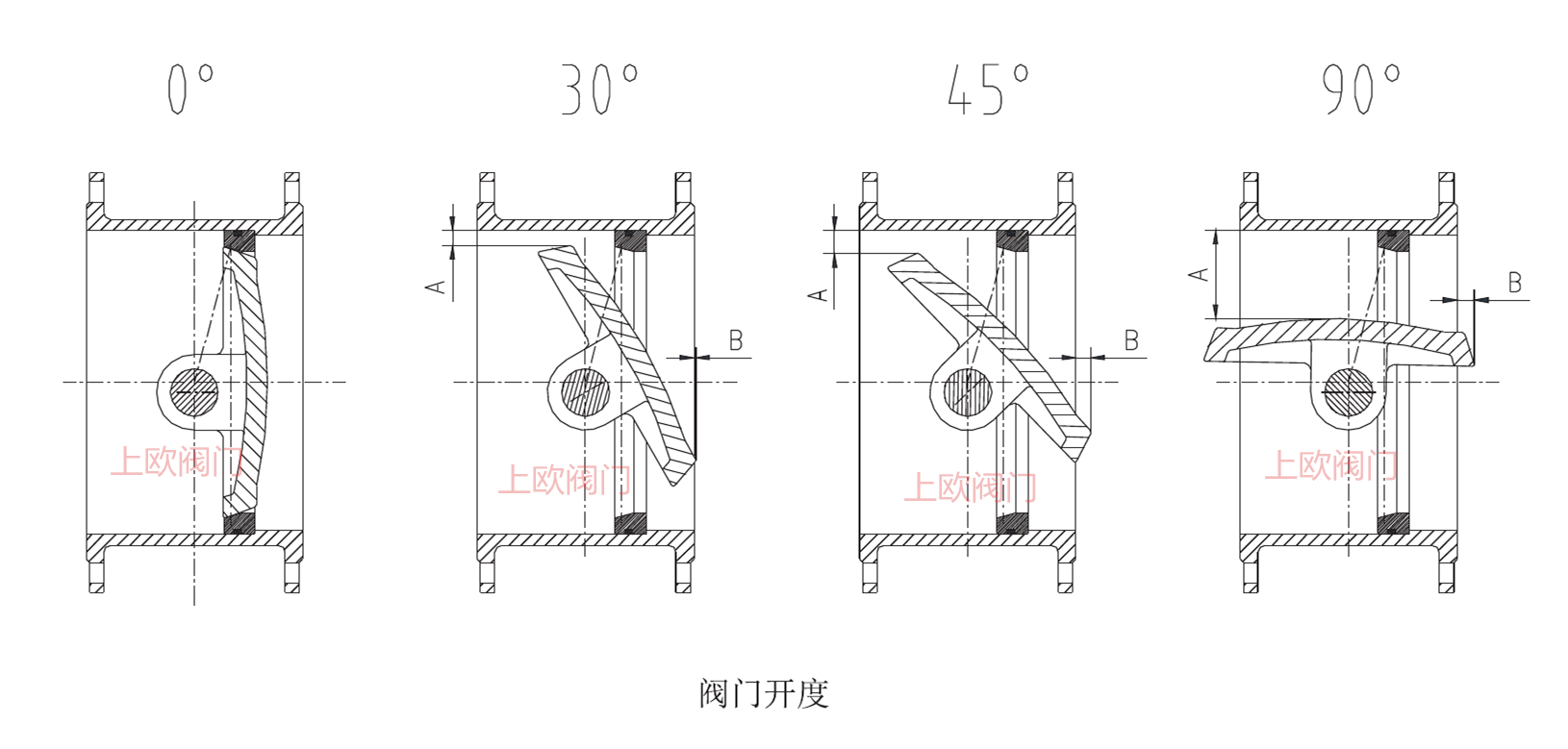

Open the change diagram of different angles:

The main function of the two-way flow valve is that it can not only seal well under the forward pressure, but also seal well when the reverse pressure or the reverse pressure is greater than the positive pressure. When the positive pressure is applied, the medium pressure pushes the valve plate to move forward, and the valve rod is elastically deformed. The sealing surface of the valve plate is close to the sealing surface of the valve seat to transmit pressure and push the valve seat to the valve body step to make it well sealed. When the reverse pressure acts, the medium pressure pushes the valve plate to move backward, and the valve rod is elastically deformed. The medium pressure simultaneously pushes the valve seat to move backward, so that the sealing surface of the valve seat is close to the sealing surface of the valve plate, and the sealing specific pressure is maintained to make the valve seat seal well.

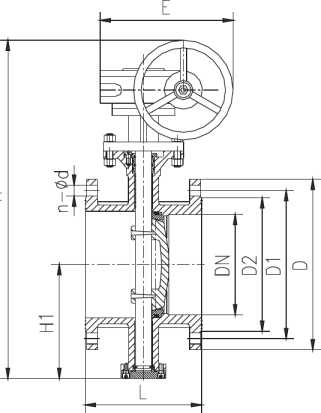

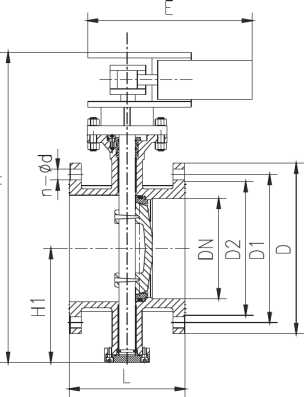

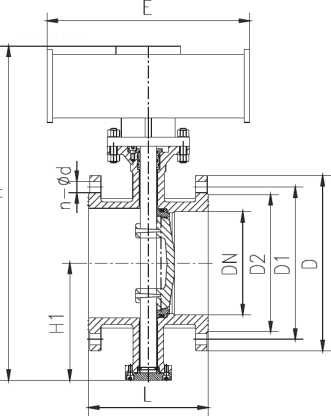

蜗杆驱动与液动阀门:

|

|

| 涡轮驱动 | 液压驱动(液动) |

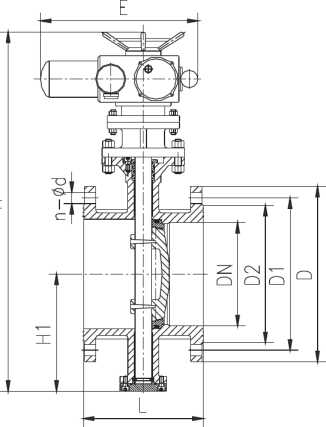

电动与气动阀门:

|

|

| 气动结构 | 电动结构 |

Connection and installation dimension table of 0.6-1.0mpa bidirectional hard seal ball valve

|

DN |

0.6MPa |

1.OMPa |

L |

H |

E |

H |

||||||||||||

|

D |

D1 |

D2 |

N-d |

D |

D1 |

D2 |

N-d |

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | |||||

|

150 |

265 |

225 |

199 |

8-18 |

285 |

240 |

211 |

8-22 |

140 |

175 |

280 |

355 |

315 |

555 |

800 |

705 |

||

|

200 |

320 |

280 |

254 |

8-18 |

340 |

295 |

266 |

8-22 |

152 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

||

|

250 |

375 |

335 |

309 |

12-18 |

395 |

350 |

319 |

12-22 |

165 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

||

|

300 |

440 |

395 |

363 |

12-22 |

445 |

400 |

370 |

12-22 |

178 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

||

|

350 |

490 |

445 |

413 |

12-22 |

505 |

460 |

429 |

16-22 |

190 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

||

|

400 |

540 |

495 |

463 |

16-22 |

565 |

515 |

480 |

16-26 |

216 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

||

|

450 |

595 |

550 |

518 |

16-22 |

615 |

565 |

530 |

20-26 |

222 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

||

|

500 |

645 |

600 |

568 |

20-22 |

670 |

620 |

582 |

20-26 |

229 |

380 |

580 |

650 |

714 |

1305 |

1290 |

1415 |

||

|

600 |

755 |

705 |

667 |

20-26 |

780 |

725 |

682 |

20-30 |

267 |

450 |

660 |

850 |

810 |

1340 |

1455 |

1605 |

||

|

700 |

860 |

810 |

772 |

24-26 |

895 |

840 |

794 |

24-30 |

292 |

480 |

550 |

850 |

810 |

1520 |

1585 |

1844 |

||

|

800 |

975 |

920 |

878 |

24-30 |

1015 |

950 |

901 |

24-33 |

318 |

530 |

550 |

1250 |

810 |

1710 |

1700 |

2040 |

||

|

900 |

1075 |

1020 |

978 |

24-30 |

1115 |

1050 |

1001 |

28-33 |

330 |

580 |

550 |

1250 |

863 |

1810 |

1965 |

2255 |

||

|

1000 |

1175 |

1120 |

1078 |

28-30 |

1230 |

1160 |

1112 |

28-36 |

410 |

650 |

750 |

1250 |

863 |

1960 |

2015 |

2380 |

||

|

1200 |

1405 |

1340 |

1295 |

32-33 |

1455 |

1380 |

1328 |

32-39 |

470 |

760 |

925 |

1250 |

863 |

2250 |

2250 |

2640 |

||

|

1400 |

1630 |

1560 |

1510 |

36-36 |

1675 |

1590 |

1530 |

36-42 |

530 |

850 |

925 |

1250 |

1055 |

2434 |

2550 |

2866 |

||

|

1600 |

1830 |

1760 |

1710 |

40-36 |

1915 |

1820 |

1750 |

40-48 |

600 |

1030 |

925 |

1250 |

1055 |

2780 |

2750 |

3156 |

||

|

1800 |

2045 |

1970 |

1918 |

44-39 |

2115 |

2020 |

1950 |

44-48 |

670 |

1230 |

980 |

1250 |

1183 |

3020 |

2950 |

3421 |

||

|

2000 |

2265 |

2180 |

2125 |

48-42 |

2325 |

2230 |

2150 |

48-48 |

760 |

1350 |

980 |

1500 |

1286 |

3270 |

3350 |

3685 |

||

|

2200 |

2485 |

2400 |

2340 |

52-42 |

2560 |

2440 |

2400 |

52-56 |

800 |

1300 |

|

|

|

|

|

|

||

|

2400 |

2685 |

2600 |

2540 |

56-42 |

2760 |

2650 |

2610 |

56-56 |

850 |

1400 |

|

|

|

|

|

|

||

|

2600 |

2905 |

2810 |

2740 |

60-48 |

2960 |

2850 |

2810 |

60-56 |

900 |

1500 |

|

|

|

|

|

|

||

|

2800 |

3115 |

3020 |

2960 |

64-48 |

3180 |

3070 |

3030 |

64-56 |

950 |

1610 |

|

|

|

|

|

|

||

|

3000 |

3315 |

3220 |

3160 |

68-48 |

3400 |

3290 |

3250 |

68-68 |

1000 |

1720 |

|

|

|

|

|

|

||

|

1.6MPa |

2.5MPa |

L |

H |

E |

H |

|||||||||||

|

D |

D1 |

D2 |

N-d |

D |

D1 |

D2 |

N-d |

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | |||

|

150 |

285 |

240 |

211 |

8-22 |

300 |

250 |

211 |

8-26 |

140 |

175 |

280 |

355 |

315 |

555 |

800 |

705 |

|

200 |

340 |

295 |

266 |

12-22 |

360 |

310 |

274 |

12-26 |

152 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

|

250 |

405 |

355 |

319 |

12-26 |

425 |

370 |

330 |

12-30 |

165 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

|

300 |

460 |

410 |

370 |

12-26 |

485 |

430 |

389 |

16-30 |

178 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

|

350 |

520 |

470 |

429 |

16-26 |

555 |

490 |

448 |

16-33 |

190 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

|

400 |

580 |

525 |

480 |

16-30 |

620 |

550 |

503 |

16-36 |

216 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

|

450 |

640 |

585 |

548 |

20-30 |

670 |

600 |

548 |

20-36 |

222 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

|

500 |

715 |

650 |

609 |

20-33 |

730 |

660 |

609 |

20-36 |

229 |

380 |

580 |

650 |

714 |

1305 |

1290 |

1415 |

|

600 |

840 |

770 |

720 |

20-36 |

845 |

770 |

720 |

20-39 |

267 |

450 |

660 |

850 |

810 |

1340 |

1455 |

1605 |

|

700 |

910 |

840 |

794 |

24-36 |

960 |

875 |

820 |

24-42 |

292 |

480 |

550 |

850 |

810 |

1520 |

1585 |

1844 |

|

800 |

1025 |

950 |

901 |

24-39 |

1085 |

990 |

928 |

24-48 |

318 |

530 |

550 |

1250 |

810 |

1710 |

1700 |

2040 |

|

900 |

1125 |

1050 |

1001 |

28-39 |

1185 |

1090 |

1028 |

28-48 |

330 |

580 |

550 |

1250 |

863 |

1810 |

1965 |

2255 |

|

1000 |

1255 |

1170 |

1112 |

28-42 |

1320 |

1210 |

1140 |

28-55 |

410 |

650 |

750 |

1250 |

863 |

1960 |

2015 |

2380 |

|

1200 |

1485 |

1390 |

1328 |

32-48 |

1530 |

1420 |

1350 |

32-55 |

470 |

760 |

925 |

1250 |

863 |

2250 |

2250 |

2640 |

|

1400 |

1685 |

1590 |

1530 |

36-48 |

1755 |

1640 |

1560 |

36-60 |

530 |

850 |

925 |

1250 |

1055 |

2434 |

2550 |

2866 |

|

1600 |

1930 |

1820 |

1750 |

40-55 |

1975 |

1860 |

1780 |

40-60 |

600 |

1030 |

925 |

1250 |

1055 |

2780 |

2750 |

3156 |

|

1800 |

2130 |

2020 |

1950 |

44-55 |

2195 |

2070 |

1985 |

44-68 |

670 |

1230 |

980 |

1250 |

1183 |

3020 |

2950 |

3421 |

|

2000 |

2345 |

2230 |

2150 |

48-60 |

2425 |

2300 |

2210 |

48-68 |

760 |

1350 |

980 |

1500 |

1286 |

3270 |

3350 |

3685 |

Connection and installation dimension table of 1.6-2.5mpa bidirectional hard seal ball valve

4.0-6.3mpa bidirectional hard seal ball valve connection and installation dimension table

|

DN |

4.0MPa |

6.3MPa |

L |

H |

E |

H |

|||||||||||

|

D |

D1 |

D2 |

N-d |

D |

D1 |

D2 |

N-d |

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | ||||

|

300 |

250 |

211 |

8-26 |

345 |

280 |

211 |

8-33 |

140 |

175 |

280 |

355 |

315 |

555 |

800 |

705 |

||

|

200 |

375 |

320 |

284 |

12-30 |

415 |

345 |

284 |

12-36 |

152 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

|

|

250 |

450 |

385 |

345 |

12-33 |

470 |

400 |

345 |

12-36 |

165 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

|

|

300 |

515 |

450 |

409 |

16-33 |

530 |

460 |

409 |

16-36 |

178 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

|

|

350 |

580 |

510 |

465 |

16-36 |

600 |

525 |

465 |

16-39 |

190 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

|

|

400 |

660 |

585 |

535 |

16-39 |

670 |

585 |

535 |

16-42 |

216 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

|

|

450 |

685 |

610 |

560 |

20-39 |

|

|

|

|

222 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

|

|

500 |

755 |

670 |

615 |

20-42 |

|

|

|

|

229 |

380 |

580 |

650 |

714 |

1305 |

1290 |

1415 |

|

|

600 |

890 |

795 |

735 |

20-48 |

|

|

|

|

267 |

450 |

660 |

850 |

810 |

1340 |

1455 |

1605 |

|

Note: for other pressure levels, please consult the technical department of the company. Different connection standards can be designed and produced according to user requirements.

Due to product improvement, there may be differences between the material object and the publicity materials. The company reserves the right to interpret the above data. Please contact the company's technical department when ordering specific parameters.

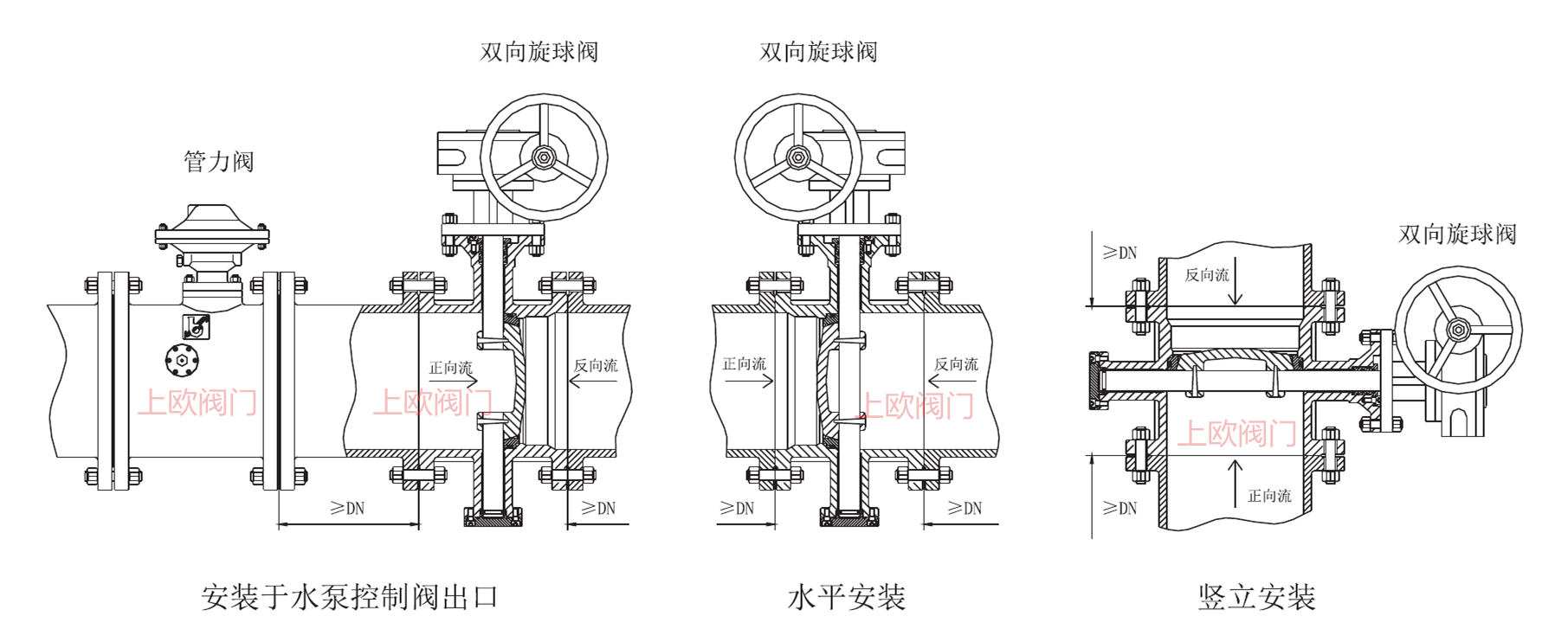

1)There shall be no reduction, elbow, bellows, etc. on the pipes within 0.5dn length before and after the installation;

2)If butterfly valve, pipe force valve, butterfly check valve or butterfly slow closing check valve are installed immediately before and after the valve, the distance between two adjacent valves is 1.0dn;

3)During assembly, installation, transportation, maintenance and repair or disassembly of valve plate, pay attention not to touch the sealing surface and take strict protection measures;

4)The valve plate shall be closed during assembly, transportation, installation and storage;

5)If it is necessary to disassemble, pay attention not to damage the shaft sleeve to prevent the loss of taper pin and shaft sleeve;

6)After assembly, installation, maintenance and repair, the metal chips, dirt and impurities in the valve shall be removed, and the sealing surface of surfacing welding shall be wiped clean;

7)Regardless of horizontal or vertical installation, when the flow direction cannot be determined, when the valve is opened, the butterfly valve has a large face and the end is facing the inlet direction;

8)If it is not used for a long time, please coat the sealing surface with grease or oil paper, and cover the sealing surface with wax paper.

Comparison of two way hard seal ball valve with other valves with some functions

| Two way hard seal ball valve | Soft seal center line butterfly valve | Multi level butterfly valve | Eccentric hemisphere valve | |

| 1. It can be reliably sealed in both directions and can meet the national pressure test standard | It can be pressurized in both directions and sealed by rubber deformation at the edge | It can't be sealed in both directions. When the reverse direction reaches 0.1-0.3mpa, it will open automatically and leak water | However, permanent deformation can occur in both directions | Can't double direction, reverse automatic opening, water leakage |

| 2. The sealing surface of valve seat and valve core can be made into high hard sealing surface | The less side of valve seat or valve plate is rubber soft seal | The less side of valve seat or valve plate is multi-layer structure (i.e. superposition of multi-layer stainless steel sheet and multi-layer graphite) | - the edge is a fully formed stainless steel elastic sheet, | Both sides can be stacked hard, but if the sphere is too hard, it is difficult to ensure the machining accuracy |

| 3. It has the function of sealing automatic compensation after wear | Once the rubber is worn and damaged, the seal will be invalid | It can't be compensated. It will shrink and leak when it is touched by many layers | The elastic plate will fail if it is worn | It can be compensated |

| 4. When closing, it can cut off the long strip impurities and eliminate the granular impurities | High hard impurities will damage the seal | Impurities will destroy the graphite part of the multilayer structure and make the seal invalid | The strength of the elastic sheet is low and easy to be destroyed by impurities | When closing, it can cut off the long strip impurities and eliminate the granular impurities |

| 5. There is no friction between the sealing surface of valve core and valve seat when closing | It's completely rubbed into the seal | High precision three eccentric without friction, otherwise there is friction | The friction is very serious | There is no friction between the sealing surface of valve core and valve seat when closing |

| The structure is short in length and light in weight. It can be made into valve with caliber | The structure is short in length and light in weight. It can be made into valve with large diameter | The structure is short in length and light in weight. It can be made into large diameter valve | Long structure, heavy weight, can not be made into large diameter valve |

自动水力控制阀进出口压力推荐及防.....

Maintenance Manu.....

V-type ball valve is a kind of.....蝶阀常见的试验和安装及故障排除方.....

1、本产品无论是手动、气动、液动、电动各部件在出厂前均经严.....管力阀八大技术特点分析

管力阀八大技术特点分析旋球阀产品概述

旋球阀结合球阀的优越密 封性能与蝶阀的优势结构性能研发而成,.....常用球阀等产品所执行的国家标准解.....

《通用阀门法兰和对焊连接钢制球阀》GB/T12237-89 .....管力阀是一种什么样的阀门

管力阀是我公司历时五年研发的zui新水泵出口控制阀,是继老.....调流调压阀焊接技术要求

调流调压阀是一种多功能活塞式调节阀、该产品有活塞式、套筒式、.....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website