Telephone:

0577-67975099

Location:Home > Product Center > Check Valve > Axial flow check valve

Location:Home > Product Center > Check Valve > Axial flow check valve

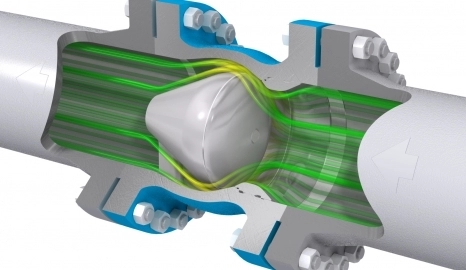

With the advantages of low flow resistance coefficient, low water hammer pressure, low noise, good flow performance and fast response, the axial flow check valve is widely used in oil and gas long-distance pipeline, compressor and pump outlet of large-scale ethylene plant. As the key part of pipeline system, the performance and life of check valve directly affect the safety of pump unit and pipeline. Especially when the valve is closed, the instantaneous velocity of the disc directly affects the impact load of the disc on the valve seat, and affects the service life and reliability of the valve. When analyzing the dynamic performance of axial check valve, the traditional test method often consumes a lot of time and money, which greatly increases the production cost of the product.

With the advantages of low flow resistance coefficient, low water hammer pressure, low noise, good flow performance and fast response, the axial flow check valve is widely used in oil and gas long-distance pipeline, compressor and pump outlet of large-scale ethylene plant. As the key part of pipeline system, the performance and life of check valve directly affect the safety of pump unit and pipeline. Especially when the valve is closed, the instantaneous velocity of the disc directly affects the impact load of the disc on the valve seat, and affects the service life and reliability of the valve. When analyzing the dynamic performance of axial check valve, the traditional test method often consumes a lot of time and money, which greatly increases the production cost of the product.

The device is suitable for clean natural gas, water, steam and other medium pipelines under the temperature of - 29 ~ 100 ℃. It has the advantages of small flow resistance, good flow state and long service life. It is an ideal device to prevent medium reverse flow.

1. Before valve installation, it is necessary to check whether there are welding slag, crushed stone and other foreign matters in the adjacent pipeline and valve, and keep the valve cavity clean;

2. Confirm that the flow direction of valve identification is consistent with the flow direction of pipeline medium;

3. Confirm whether the diameter, pressure, medium temperature and other parameters of the pipeline system used are consistent with the valve identification;

1. Before valve installation, it is necessary to check whether there are welding slag, crushed stone and other foreign matters in the adjacent pipeline and valve, and keep the valve cavity clean;

2. Confirm that the flow direction of valve identification is consistent with the flow direction of pipeline medium;

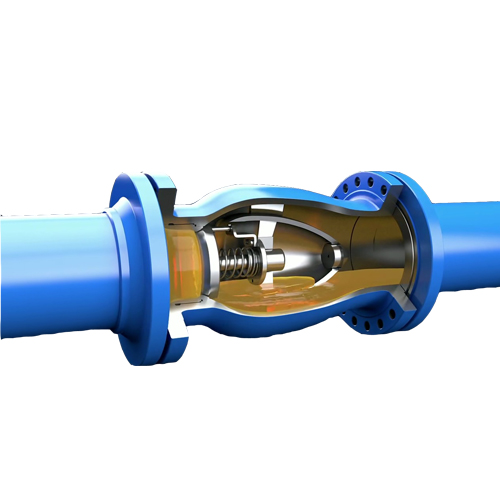

3. Confirm whether the diameter, pressure, medium temperature and other parameters of the pipeline system used are consistent with the valve identification; 1. The product is composed of valve body, guide body, axial movement disc and spring components. The product can effectively prevent the backflow of media. Ensure pipeline safety.

2. The valve body, disc and tail vertebrae are designed into streamlined channels, which have good fluid performance and minimize flow resistance and pressure.

3. The high performance spring material HT / inconelx-750 has excellent corrosion resistance, oxidation resistance and excellent mechanical properties to ensure the long-term operation of the spring.

4. Silent operation, so as to eliminate the noise and water hammer in the valve pipeline and ensure the safety of equipment and pipeline.

5. Quick response of opening and closing, high reliable preloading spring makes the valve disc respond quickly to the change of fluid pressure.

6. Compact structure, convenient installation, vertical and horizontal installation.

7. The valve adopts alloy steel surfacing sealing surface, which is wear-resistant, corrosion-resistant and has long service life.

8. The pressure range of the valve is relatively wide.

1. The product is composed of valve body, guide body, axial movement disc and spring components. The product can effectively prevent the backflow of media. Ensure pipeline safety.

2. The valve body, disc and tail vertebrae are designed into streamlined channels, which have good fluid performance and minimize flow resistance and pressure.

3. The high performance spring material HT / inconelx-750 has excellent corrosion resistance, oxidation resistance and excellent mechanical properties to ensure the long-term operation of the spring.

4. Silent operation, so as to eliminate the noise and water hammer in the valve pipeline and ensure the safety of equipment and pipeline.

5. Quick response of opening and closing, high reliable preloading spring makes the valve disc respond quickly to the change of fluid pressure.

6. Compact structure, convenient installation, vertical and horizontal installation.

7. The valve adopts alloy steel surfacing sealing surface, which is wear-resistant, corrosion-resistant and has long service life.

8. The pressure range of the valve is relatively wide.

| model |

ACH41H-16C/P |

ACH41H-25C/P |

ACH41W-40 |

ACH41W-64 |

ACH41H-100 |

|

| Nominal pressure |

PN16 |

PN25 |

PN40 |

PN64 |

PN100 |

|

|

2.4 |

3.8 |

6.0 |

9.6 |

15.0 |

|

| High pressure seal |

1.8 |

2.8 |

4.4 |

7.1 |

11.0 |

|

| Applicable media | Water, oil, gas, etc | |||||

| Applicable temperature |

≤400℃ |

|||||

| valve body | Disc | Deflector | Sealing pair | Stem | Spring |

| Cast steel WCB CF8 | Cast steel WCB CF8 | Cast steel WCB CF8 | Surfacing of stainless steel |

1Gr18Ti9 |

HT/INCONELX-750 |

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website