Telephone:

0577-67975099

Location:Home > Product Center > Check Valve > Butterfly check valve with micro resistance and slow closing

Location:Home > Product Center > Check Valve > Butterfly check valve with micro resistance and slow closing

This series of butterfly check valve with small resistance and slow closing adopts swash plate large eccentric design and double eccentric structure. At the same time, it is equipped with a graded buffer cylinder, which can realize two-stage closing, that is, fast closing 85% - 90% (not subject to cylinder damping), and then slowly closing 10% - 15% (subject to cylinder yangni). The slow closing time can be adjusted to achieve the best effect of eliminating water hammer. It is installed at the outlet of the pump to prevent destructive water hammer when the pump is stopped. Therefore, the valve can be widely used in municipal, power plant, metallurgy, petrochemical and other industries of water supply and drainage system.

This series of butterfly check valve with small resistance and slow closing adopts swash plate large eccentric design and double eccentric structure. At the same time, it is equipped with a graded buffer cylinder, which can realize two-stage closing, that is, fast closing 85% - 90% (not subject to cylinder damping), and then slowly closing 10% - 15% (subject to cylinder yangni). The slow closing time can be adjusted to achieve the best effect of eliminating water hammer. It is installed at the outlet of the pump to prevent destructive water hammer when the pump is stopped. Therefore, the valve can be widely used in municipal, power plant, metallurgy, petrochemical and other industries of water supply and drainage system.

It adopts swash plate large eccentricity design and double eccentric structure, which has good dynamic performance of opening and closing, low opening pressure (≤ 0.08mpa), small flow resistance, small vibration, no need of heavy hammer and obvious energy saving effect.

The slow closing device has the advantages of novel design, compact and reasonable structure, reliable performance, fast and slow closing time. The slow closing time of slow closing section is adjustable from 1 to 60 seconds, which can be applied to different working conditions and reduce the impact of water hammer.

The valve shaft is of inertia type, safe and reliable. The back end of the valve body adopts the axial adjustable mechanism of the valve disc, with good sealing effect and adjustable zero leakage.

The bearing of valve shaft adopts self lubrication bearing, with small friction resistance and no need of oil injection.

The valve disc and valve shaft are connected by pull-out pin structure, which is closely combined without gap, and the shaft disc connection is more firm.

There are soft and hard sealing structure for users to choose according to different working conditions.

| Nominal diameter |

250~2000 |

|||

|

Nominal pressurePN(MPa) |

0.6 |

1.0 |

1.6 |

|

| Test pressure | seal up |

0.66 |

1.1 |

1.76 |

| housing |

0.9 |

1.5 |

2.4 |

|

| Applicable media | Sewage, clean water, mud, oil, etc | |||

| Standard materials | valve body | Ductile iron | ||

| Disc | Ductile iron | |||

| valve seat | Stainless steel, aluminum alloy | |||

| stainless steel | ||||

| seal ring | Engineering plastics, rubber, stainless steel, copper alloy | |||

| Flange connection standard |

accord withGB/T17241.6-2008 (IS07005.2) |

| Structural length standard |

GB12221-2005 14series (IS05752)Size specification |

| Test standard |

GB/T26480-2011 (API STD.598)implement |

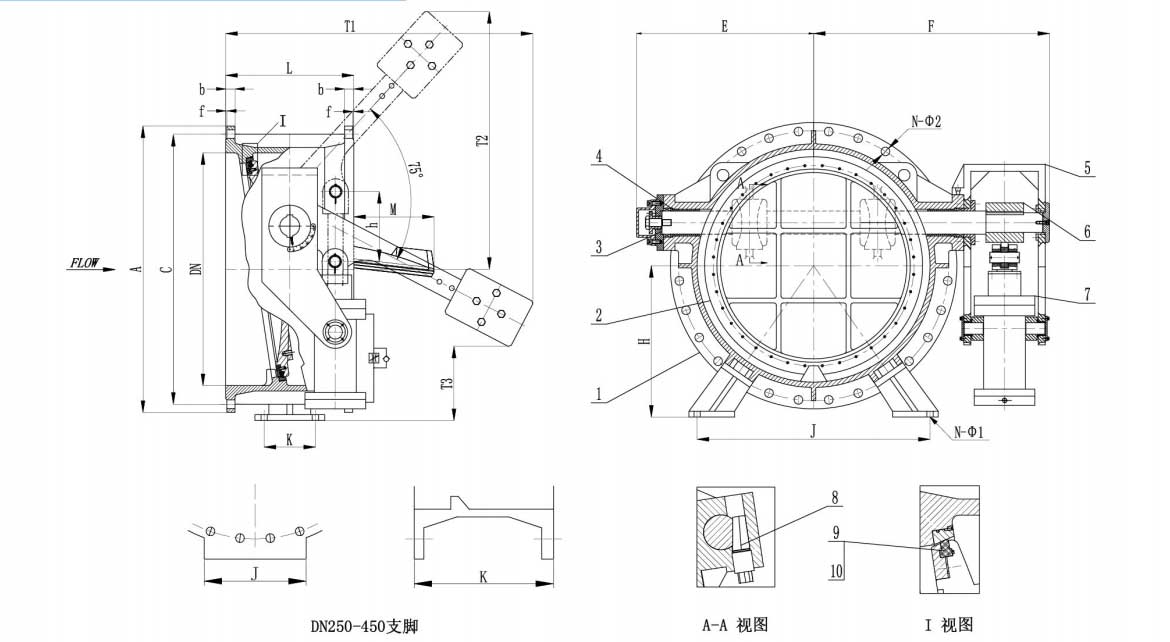

This type of check valve is mainly composed of valve body, disc, rotating shaft, rocker arm, buffer hydraulic cylinder, etc. The valve is driven by the inlet pressure to open the valve disc to make the medium pass through. The valve disc drives the rocker arm through the rotating shaft to pull the piston rod in the buffer cylinder to the open position. When the medium stops flowing (e.g. the pump stops suddenly), the valve disc will close automatically due to the self weight of the valve disc and the effect of medium backflow. Due to the action of buffer device, the valve disc closing is divided into two stages.

The first stage: from the full open position to 85% - 90% of the stroke is the fast closing section. In this stage, the valve disc drives the rocker arm to move clockwise at the same time, and the cylinder piston rod is pressed back into the cylinder block. At this stage, the damping device has little effect and the valve disc closing speed is very high. The second stage: from 85% to 90% of the stroke to the full closing is the slow closing section. In this stage, the damping device plays a very important role. In order to obtain the appropriate closing speed, the damping value of the oil system can be adjusted by adjusting the opening of the one-way throttle valve, so as to eliminate the destructive water hammer and protect the pump, valve and pipeline system

| Serial number | name | texture of material | Serial number | name | texture of material |

|

1 |

valve body |

QT450-10 |

6 |

rocker arm | |

|

2 |

Disc |

QT450-10 |

7 |

Buffer cylinder | Assembly |

|

3 |

Shaft |

2Cr13 |

8 |

Withdrawal pin |

1Cr17Ni2 |

|

4 |

Bearing |

ZCuAl10Fe3 |

9 |

Disc seal ring | polypropylene |

|

5 |

Cylinder bracket |

Q235-A |

10 |

valve seat |

0Cr19Ni9 |

|

DN |

A |

C |

b |

f |

L |

E |

F |

H |

J |

K |

M |

T1 |

T2 |

T3 |

N-φ1 |

N-φ2 |

||||||||

|

PN6 |

PN10 |

PN16 |

PN6 |

PN10 |

PN16 |

PN6 |

PN10 |

PN16 |

PN6 |

PN10 |

PN16 |

|||||||||||||

|

250 |

375 |

395 |

405 |

335 |

350 |

355 |

22 |

22 |

22 |

3 |

250 |

260 |

355 |

270 |

250 |

250 |

30 |

418 |

297 |

115 |

|

12-φ19 |

12-φ23 |

12-φ28 |

|

300 |

|

445 |

460 |

|

400 |

410 |

|

24.5 |

24.5 |

4 |

270 |

247 |

356 |

280 |

250 |

270 |

52 |

428 |

304 |

134 |

|

|

12-φ23 |

12-φ28 |

|

350 |

|

505 |

520 |

|

460 |

470 |

|

24.5 |

26.5 |

4 |

290 |

313 |

385 |

300 |

300 |

290 |

73 |

473 |

342 |

144 |

|

|

16-φ23 |

16-Φ28 |

|

400 |

|

565 |

580 |

|

515 |

525 |

|

24.5 |

28 |

4 |

310 |

343 |

470 |

350 |

400 |

310 |

94 |

387 |

404 |

157 |

|

|

16-φ28 |

20-φ31 |

|

450 |

|

615 |

640 |

|

565 |

585 |

|

25.5 |

30 |

4 |

330 |

377 |

512 |

350 |

400 |

330 |

109 |

552 |

408 |

161 |

|

|

20-φ28 |

20-φ31 |

|

500 |

|

670 |

715 |

|

620 |

650 |

|

26.5 |

31.5 |

4 |

350 |

417 |

568 |

400 |

500 |

150 |

139 |

699 |

566 |

223 |

4-φ21 |

|

20-φ28 |

20-φ34 |

|

600 |

|

780 |

840 |

|

725 |

770 |

|

30 |

36 |

5 |

390 |

477 |

640 |

450 |

600 |

150 |

181 |

819 |

671 |

251 |

4-φ23 |

|

20-Φ31 |

20-Φ37 |

|

700 |

|

895 |

810 |

|

840 |

840 |

|

32.5 |

39.5 |

5 |

430 |

542 |

705 |

500 |

700 |

150 |

241 |

930 |

782 |

293 |

4-Φ23 |

|

24-φ31 |

24-Φ37 |

|

800 |

|

1015 |

910 |

|

950 |

950 |

|

35 |

43 |

5 |

470 |

610 |

854 |

550 |

780 |

180 |

246 |

1067 |

875 |

278 |

4-Φ26 |

|

24-Φ34 |

24-Φ40 |

|

900 |

|

1115 |

1025 |

|

1050 |

1050 |

|

37.5 |

46.5 |

5 |

510 |

642 |

879 |

600 |

900 |

200 |

302 |

1087 |

906 |

363 |

4-Φ26 |

|

28-φ34 |

28-Φ40 |

|

1000 |

1175 |

1230 |

1125 |

1120 |

1160 |

1170 |

40 |

40 |

50 |

5 |

550 |

760 |

1016 |

650 |

1000 |

220 |

345 |

1318 |

1106 |

349 |

4-φ27 |

28-φ31 |

28-φ37 |

28-φ43 |

|

1200 |

1405 |

1455 |

1255 |

1340 |

1380 |

|

45 |

45 |

|

5 |

630 |

902 |

1158 |

800 |

1200 |

230 |

504 |

1365 |

1213 |

579 |

4-φ27 |

32-Φ34 |

32-Φ40 |

|

|

1400 |

1630 |

1675 |

|

1560 |

1590 |

|

46 |

46 |

|

5 |

710 |

1076 |

1447 |

930 |

1400 |

230 |

514 |

1604 |

1372 |

588 |

4-φ33 |

36-Φ37 |

36-Φ43 |

|

|

1600 |

1830 |

1915 |

|

1760 |

1820 |

|

49 |

49 |

|

5 |

790 |

1220 |

1568 |

1020 |

1600 |

230 |

624 |

1739 |

1496 |

686 |

4-φ33 |

40-Φ37 |

40-Φ49 |

|

|

1800 |

2045 |

2115 |

|

1970 |

2020 |

|

52 |

52 |

|

5 |

870 |

1338 |

1668 |

1150 |

1800 |

240 |

695 |

2028 |

1726 |

753 |

4-Φ40 |

44-Φ40 |

44-Φ49 |

|

|

2000 |

2265 |

2325 |

|

2180 |

2230 |

|

55 |

55 |

|

5 |

950 |

1438 |

1768 |

1280 |

2000 |

310 |

830 |

2028 |

1774 |

928 |

4-Φ40 |

48-Φ43 |

48-Φ49 |

|

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website