Telephone:

0577-67975099

Location:Home > Product Center > control valve > SADKMulti function axial flow control valve

Location:Home > Product Center > control valve > SADKMulti function axial flow control valve

Sadk multi-functional axial flow control valve has the advantages of simple structure, large flow coefficient, small dynamic load bearing capacity, and can be used for any water head. It can be arranged horizontally, vertically and obliquely. It is widely used for flow control of bypass, reservoir discharge or continuous discharge, especially for discharge of downstream environmental protection flow and supplement of downstream river flow in dry season. The valve is an important equipment in the modernization of water conservancy and hydropower projects.

-、preface

Multifunctional axial flow control valve, also known as piston valve, is a new product of Zui developed by our company on the basis of absorbing foreign technology. It has many functions, such as flow control, decompression and pressure stabilization control, pressure relief and pressure holding control, venting and energy dissipation. The valve has the advantages of novel structure, advanced performance, reliable operation and wide application

It can be used in various water supply and drainage systems of water conservancy and hydropower, metallurgy, petrochemical, water department, municipal administration, environmental protection and other industries, as well as oil and gas medium systems. (hereinafter referred to as control valve)

1、 Decompression / stabilization: the pressure reduction range is large, and the single-stage valve can be reduced from 10 Ma to 0.1 ma. And the valve operation without noise, cavitation. In the systems of high-pressure artesian water supply, high-pressure head hydropower station, deep mine, etc., water is taken from the pressure pipe, and the water can be supplied to the low-pressure manual system after one-stage decompression of the valve。

2、 Pressure relief / pressure holding: through upstream pressure sensing control and automatic valve opening and closing by electric device, the flow and pressure can be adjusted in a wide range, which can be used as the bypass discharge valve of large pump station and hydro generator unit. It also has no noise and cavitation performance.

3、 Flow control and cut-off: during the stroke from full open to full close, the valve flow system has a linear relationship with the valve opening. Even in the stroke from full close to 10% opening, it still has good flow regulation performance. Accurate flow regulation can be realized through downstream flowmeter or manual control. At the same time, the valve has cut-off function and excellent sealing effect。

4、 Venting and energy dissipation: the valve can be directly installed with the port of high-pressure pipe network as an energy dissipation and discharge valve. When water flows through the valve, it collides with each other and diffuses and ejects at a wide cone angle. It decomposes and dilutes through the impedance of the air, so as to dissipate the impact capacity and protect the downstream facilities. The beam hood can be added to effectively control the jet direction。

The sleeve is placed on the inner cavity of the valve body and guided by the guide rail. The water flows from the outside of the guide device and forms multiple streams of water through the jet hole on the deflector, which produces collision in the middle chamber of the valve body to achieve the effect of energy dissipation. The throttling occurs between the sleeve edge and the orifice of the deflector. Due to the high flow velocity in the hole, the material selected for the deflector is highly wear-resistant and corrosion-resistant. At the same time, due to the collision, the middle chamber of the valve channel is effectively reduced The influence of cavitation and erosion on valve body can improve the service life of valve. The main seal ring is located at the front end of Zui of the deflector, and the sleeve is guided in the full stroke. When it is pushed through the main seal ring to the fully closed position, the differential pressure between the front and rear of the valve forces the main seal ring to be close to the outer wall of the sleeve to realize the truncation. The sleeve moves back and forth in the cavity of the valve body through the guide of the connecting rod, and the valve rod is driven by the crank and connecting rod. When the actuator drives the valve stem to rotate against the clock, the sleeve moves backward to open the valve; when the actuator drives the valve stem to rotate clockwise, the sleeve moves forward to close the valve。

Fig. 4 Schematic diagram of valve energy dissipation

technical parameter(1MPa=10kgf/cm2)

| project | parameter |

|

Nominal pressure(MPa) |

0.6-6.3MPa |

| Leakage |

accord withGB/T13927Standard regulations |

|

Applicable temperature(℃) |

-29~120℃ |

| Applicable media | Water, air, natural gas, gas, etc |

Parameter summary table of multi function axial flow control valve

| Serial number item | parameter | remarks | ||

| One | Valve name | control valve | Can be equipped with control box (decompression / relief / flow regulation) |

|

| Two | Nominal pressure |

PN |

||

| Three |

1.5PN |

|||

| Four | Sealing test pressure |

1.1PN |

||

|

7 |

Set pressure (H / relief condition) |

Nominal pressure | Adjustment range | It can be set according to the working conditions |

|

0.05-0.9 MPa |

||||

|

1.6 MPa |

0.05-1.4 MPa |

|||

|

2.5 MPa |

0.05 -2.3 MPa |

|||

|

4.0 MPa |

01-3.8 MPa |

|||

|

6.3 MPa |

0.1-6.0 MPa |

|||

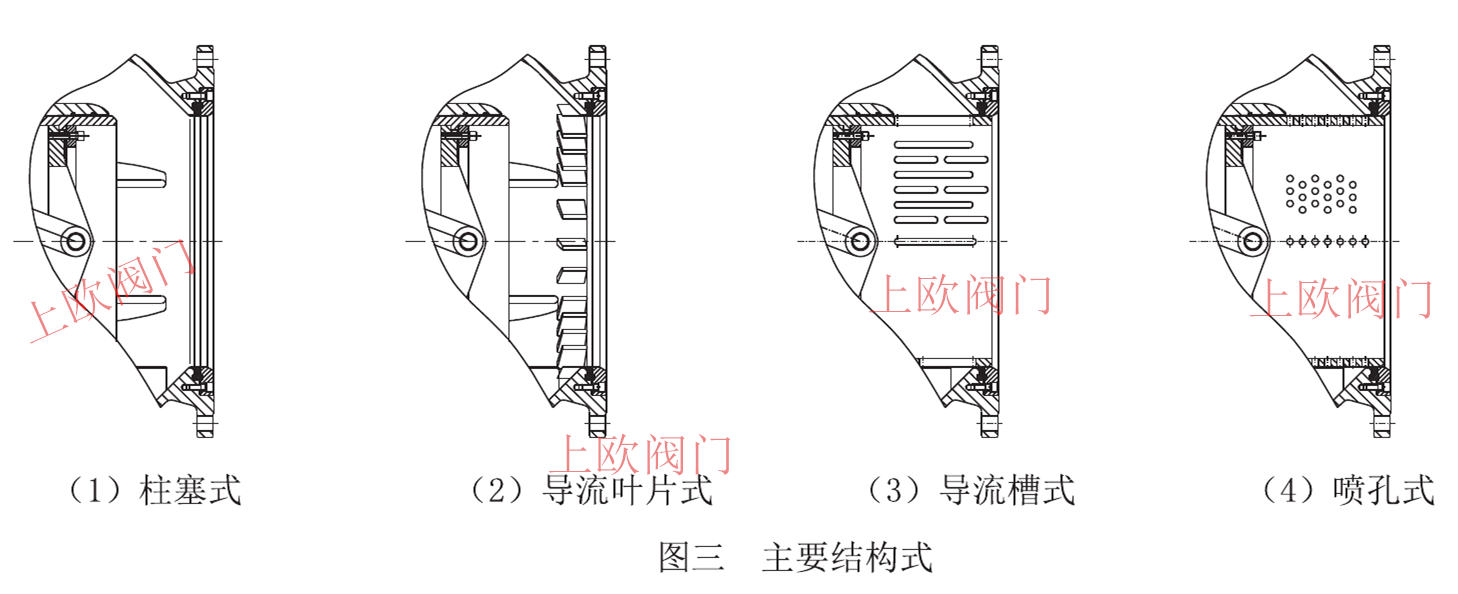

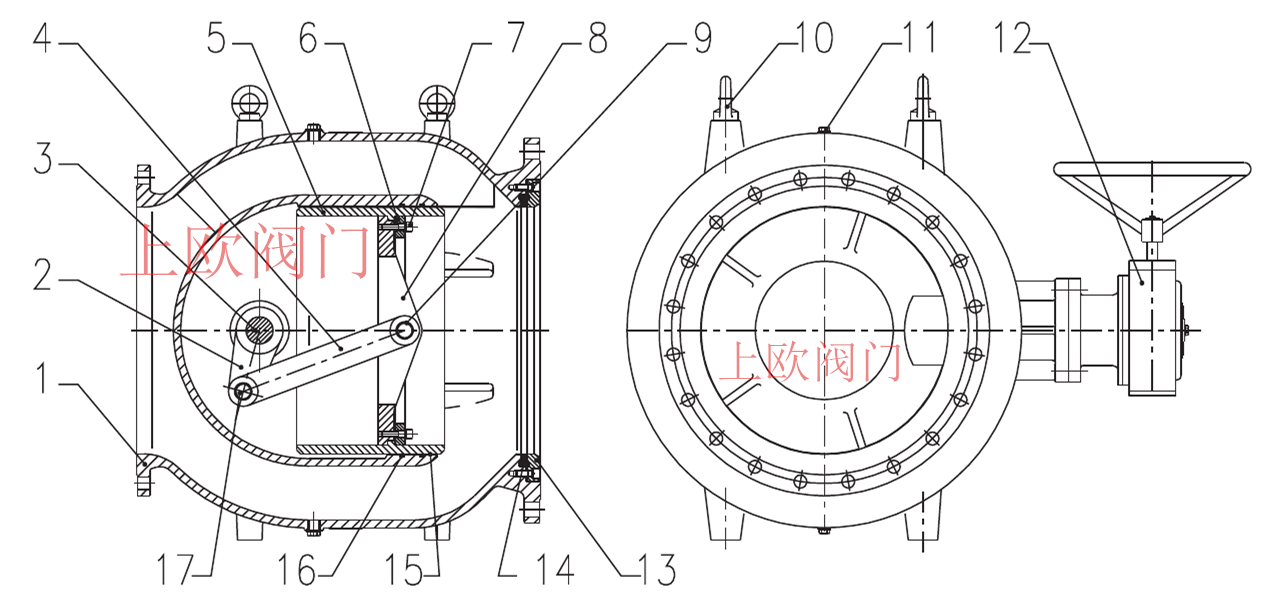

Multi function axial flow control valve is composed of valve body, stem, crank and sleeve. The deflector made of stainless steel is fixed in the middle chamber of the valve body. The deflector has guide groove type, guide vane type and spray hole type. The sleeve looper is in the valve body cavity and connected with the valve stem. The position of the sleeve is controlled by the external control parts to adjust the flow area of the valve. The external control components can be manual, electric, pneumatic and hydraulic according to the working conditions.

Fig. 2 guide vane type

The multi-functional axial flow control valve has the following four main forms, and its structure and application range are as follows:

1、Plunger type structure can be widely used in water, oil and gas systems, with simple structure, reliable operation, small head loss, and low requirements for medium cleanliness, which is the common form of Zui.

2、 Guide vane type is suitable for large pressure difference, gas-liquid mixing and other working conditions, stable operation and low cavitation.

3、 The structure of diversion groove has superior regulation performance, which can be used in high pressure differential system and working conditions with suspended particles and other impurities, and has good cavitation resistance.

4、The results show that the spray hole structure has good adjustability and the effect of flow regulation and pressure reduction for clean media under ultra-high pressure difference condition is excellent.

Fig. 1 valve structure diagram

| Serial number | name | Material Science | Serial number | name | Material Science | |

|

1 |

valve body |

Ductile ironQT450-10 /Cast steel WCB / stainless steel |

10 |

rings |

35# |

|

|

2 |

crank | Stainless copper 2Crl3 |

11 |

Plug | ||

|

3 |

Drive shaft | Stainless steel 2Crl3 |

12 |

Executive Agency | Handwheel / intelligent electric installation | |

|

4 |

connecting rod | Stainless steel 2Crl3 | 13 | Stainless steel 2Crl3 | ||

|

5 |

Sleeve | Stainless steel 304 / 316 |

14 |

Sealing element | Butadiene rubber | |

|

6 |

Sleeve gland | Stainless steel 2Crl3 |

15 |

Sleeve guide | Aluminum bronze zcuall0fe3 | |

|

7 |

a fastening | Stainless steel A2-70 |

16 |

Ink seal | Butadiene rubber | |

|

8 |

Crankshaft support | Stainless steel 2Crl3 |

17 |

Drive pin shaft | ||

|

9 |

Drive bearing |

|

|

|

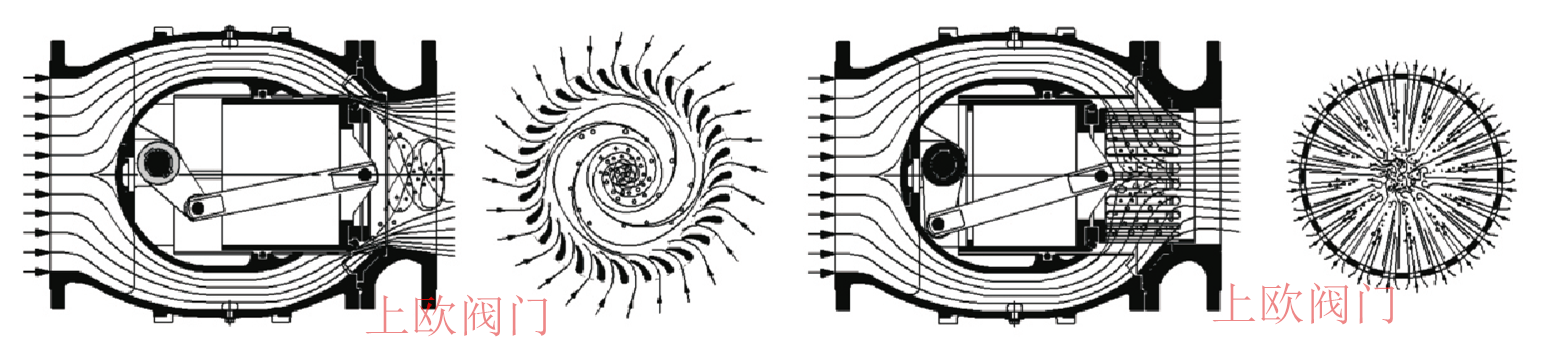

Axial symmetrical flow passage: the valve body adopts axial symmetrical flow passage, and the medium flows into the valve through streamline inner cavity. The shape of flow passage at any position in the valve is circular. Compared with the traditional valve, the flow channel of sleeve valve is smooth, and the fluid has no sharp turning under any opening, which avoids unnecessary change of flow direction, significantly reduces noise and turbulence trend, and reduces valve cavitation.

Pressure balance: because the multi-functional axial flow control valve adopts pressure balance sleeve, the axial force of operating sleeve has nothing to do with the pressure difference at both ends of the valve, so the purpose of quick action can be achieved by using smaller actuator (the opening and closing torque is only 1 / 3-1 / 5 of that of ordinary gate valve, butterfly valve and other transmission valves).

Good regulation effect: almost digital control, through changing the number of flow holes to achieve the change of flow area, with good linear regulation characteristics.

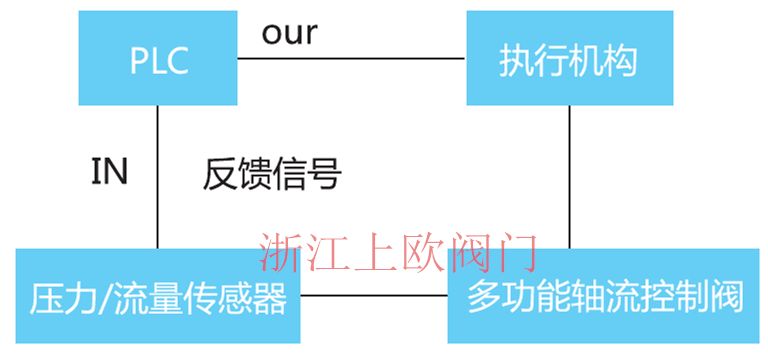

1、The pressure sensor outputs 4-20mA DC signal to calibrate the small pressure value of Zui and the large pressure value of Zui.

2、The output feedback signal of pressure sensor is sent to PLC for processing. After comparing the preset values of PLC, the corresponding control signal is output to the electric actuator, and the valve is driven to the corresponding position (valve opening).

3、 PLC is responsible for opening reservation, feedback signal comparison and control; output work, the electric actuator is responsible for driving the valve to the specified position according to the PLC command, the control precision is set by PLC, this method is closed-loop control, stable and reliable.

4、The electric actuator adopts intelligent type, which has many functions such as stroke protection, torque protection, phase failure alarm, etc.

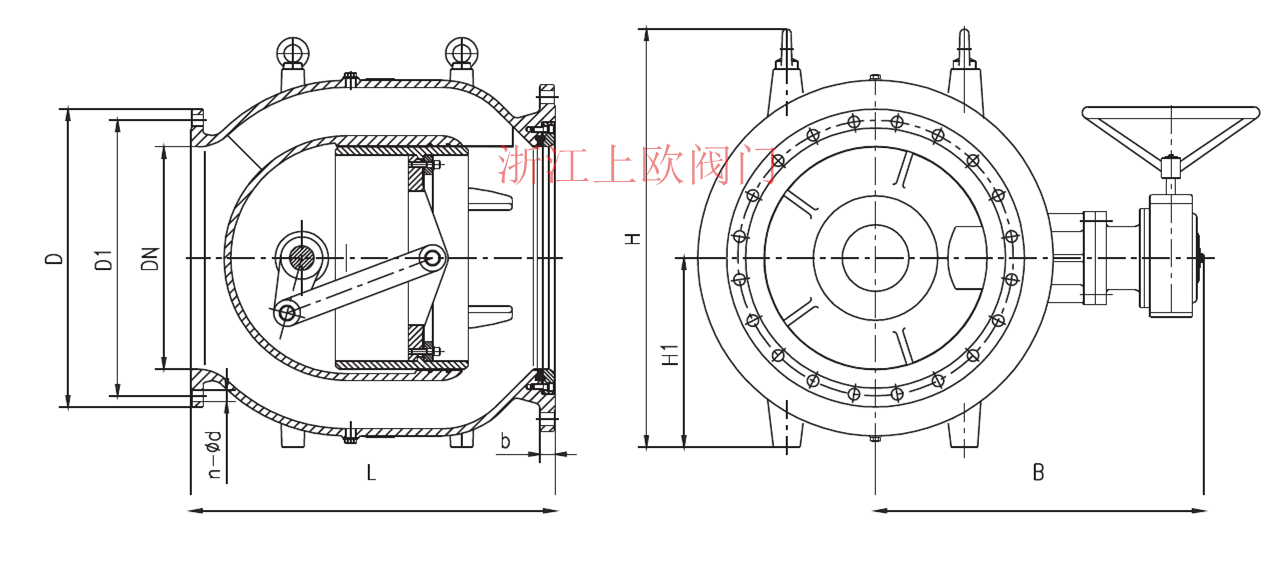

Dimension and connection dimension table of pn1.0-pn2.5mpa multifunctional axial flow control valve

| nominal Diameter |

Overall dimension (standard value) | Connection size (standard value) | ||||||||||||||

|

PN1.0 MPa |

PN1.6 MPa |

PN2.5 MPa |

||||||||||||||

|

L |

B |

H |

H1 |

D |

D1 |

n-Фd |

b |

D |

D1 |

n-Фd |

b |

D |

D1 |

n-Фd |

b |

|

|

100 |

325 |

210 |

160 |

80 |

220 |

180 |

8-Ф18 |

22 |

220 |

180 |

8-Ф18 |

22 |

235 |

190 |

8-Ф22 |

24 |

|

125 |

325 |

240 |

190 |

100 |

250 |

210 |

8-Ф18 |

22 |

250 |

210 |

8-Ф18 |

22 |

270 |

220 |

8-Ф26 |

26 |

|

150 |

350 |

290 |

220 |

150 |

285 |

240 |

8-Ф22 |

24 |

285 |

240 |

8-Ф22 |

24 |

300 |

250 |

8-Ф26 |

28 |

|

200 |

400 |

330 |

310 |

190 |

340 |

295 |

8-Ф22 |

24 |

340 |

295 |

12-Ф22 |

24 |

360 |

310 |

12-Ф26 |

30 |

|

250 |

500 |

330 |

395 |

230 |

395 |

350 |

12-Ф22 |

26 |

405 |

355 |

12-Ф26 |

26 |

425 |

370 |

12-Ф30 |

32 |

|

300 |

600 |

420 |

460 |

260 |

445 |

400 |

12-Ф22 |

26 |

460 |

410 |

12-Ф26 |

28 |

485 |

430 |

16-Ф30 |

34 |

|

350 |

700 |

510 |

490 |

300 |

505 |

460 |

16-Ф22 |

26 |

520 |

470 |

16-Ф26 |

30 |

555 |

490 |

16-Ф33 |

38 |

|

400 |

800 |

655 |

520 |

335 |

565 |

515 |

16-Ф26 |

26 |

580 |

525 |

16-Ф30 |

32 |

620 |

550 |

16-Ф36 |

40 |

|

450 |

900 |

750 |

580 |

345 |

615 |

565 |

20-Ф26 |

28 |

640 |

585 |

20-Ф30 |

40 |

670 |

600 |

20-Ф36 |

46 |

|

500 |

1050 |

820 |

640 |

385 |

670 |

620 |

20-Ф26 |

28 |

715 |

650 |

20-Ф33 |

44 |

730 |

660 |

20-Ф36 |

48 |

|

600 |

1175 |

970 |

730 |

460 |

780 |

725 |

20-Ф30 |

34 |

840 |

770 |

20-Ф36 |

54 |

845 |

770 |

20-Ф39 |

58 |

|

700 |

1320 |

1050 |

850 |

500 |

895 |

840 |

24-Ф30 |

34 |

910 |

840 |

24-Ф36 |

40 |

960 |

875 |

24-Ф42 |

50 |

|

800 |

1480 |

1215 |

1020 |

600 |

1015 |

950 |

24-Ф33 |

36 |

1025 |

950 |

24-Ф39 |

42 |

1085 |

990 |

24-Ф48 |

54 |

|

900 |

1700 |

1350 |

1270 |

700 |

1115 |

1050 |

28-Ф33 |

38 |

1125 |

1050 |

28-Ф39 |

44 |

1185 |

1090 |

28-Ф48 |

58 |

|

1000 |

1900 |

1560 |

1390 |

800 |

1230 |

1160 |

28-Ф33 |

38 |

1255 |

1170 |

28-Ф42 |

46 |

1320 |

1210 |

28-Ф55 |

62 |

|

1200 |

2100 |

1750 |

1510 |

900 |

1455 |

1380 |

32-Ф39 |

44 |

1485 |

1390 |

32-Ф48 |

52 |

1530 |

1420 |

32-Ф55 |

70 |

|

1400 |

2420 |

2100 |

1625 |

1000 |

1675 |

1590 |

36-Ф42 |

48 |

1685 |

1590 |

36-Ф48 |

58 |

1755 |

1640 |

36-Ф60 |

76 |

|

1600 |

2700 |

2435 |

1920 |

1200 |

1915 |

1820 |

40-Ф48 |

52 |

1930 |

1820 |

40-Ф55 |

64 |

1975 |

1860 |

40-Ф60 |

84 |

|

1800 |

3070 |

2670 |

2110 |

1400 |

2115 |

2020 |

44-Ф48 |

56 |

2130 |

2020 |

44-Ф55 |

68 |

|

|

|

|

|

2000 |

3250 |

1980 |

2310 |

1600 |

2325 |

2230 |

48-Ф48 |

60 |

2345 |

2230 |

48-Ф60 |

70 |

|

|

|

|

自动水力控制阀进出口压力推荐及防.....

Maintenance Manu.....

V-type ball valve is a kind of.....蝶阀常见的试验和安装及故障排除方.....

1、本产品无论是手动、气动、液动、电动各部件在出厂前均经严.....管力阀八大技术特点分析

管力阀八大技术特点分析旋球阀产品概述

旋球阀结合球阀的优越密 封性能与蝶阀的优势结构性能研发而成,.....常用球阀等产品所执行的国家标准解.....

《通用阀门法兰和对焊连接钢制球阀》GB/T12237-89 .....管力阀是一种什么样的阀门

管力阀是我公司历时五年研发的zui新水泵出口控制阀,是继老.....调流调压阀焊接技术要求

调流调压阀是一种多功能活塞式调节阀、该产品有活塞式、套筒式、.....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website