Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > Q47FType a fixed manual ball valve150(Lb)~1500(Lb)

Location:Home > Product Center > Ball Valve > Q47FType a fixed manual ball valve150(Lb)~1500(Lb)

Q47f fixed manual ball valve 150 (LB) ~ 1500 (LB) is suitable for chemical, petroleum, natural gas, metallurgy and other industries, as well as natural gas long-distance pipeline with hydrogen sulfide medium, impurities and serious corrosion.

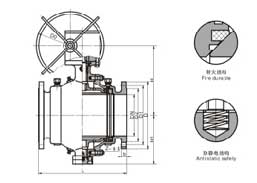

Q47FThe type 150 (LB) ~ 1500 (LB) fixed manual ball valve is suitable for chemical, petroleum, natural gas, metallurgy and other industries, as well as long-distance natural gas pipeline with hydrogen sulfide medium, impurities and serious corrosion.

1. The valve seat adopts spring structure, which pushes the valve seat to the ball to ensure good low-pressure sealing performance; 2. The valve seat before and after fixing the ball valve can be sealed, that is, the so-called two-way sealing feature. The inner cavity of the valve body can be discharged outwards by using the self-contained discharge valve; 3. The pivot adopts anti blowing protection structure and low friction coefficient bearing. It has excellent performance, high reliability and wide application;

Q47FPerformance parameters of 150 (LB) ~ 1500 (LB) type fixed manual ball valve

| model | Applicable temperature(℃) | Applicable media | Material Science |

| Q47F-16C | -29~150 | Water, steam, oil, etc | carbon steel |

| Q47F-16P | CF8 |

1. Be careful in installation and construction, and do not hit the valve.

2. Before installation, the ball valve should be inspected to check the specification and model, and identify whether there is damage, especially for the valve stem. Also turn a few times to see if it is skewed, because during transportation, it is easy to bump the stem. Also remove the debris in the valve.

3. When lifting the ball valve, the rope should not be tied to the hand wheel or the valve stem to avoid damage to these parts, but should be tied to the valve body.

4. The pipeline connected to the ball valve must be cleaned. Compressed air can be used to blow away iron oxide chips, mud and sand, welding slag and other impurities. These debris, not only easy to scratch the sealing surface of the ball valve, in which large particles of debris (such as welding slag), but also block the small valve, so that its failure.

5. The position of valve handle rotation should be reserved during installation. 6. The ball valve cannot be used as throttling. 7. The ball valve with transmission mechanism shall be installed vertically.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website