Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > GWXDF3204HTwo way flow hard impact hard ball valve

Location:Home > Product Center > Ball Valve > GWXDF3204HTwo way flow hard impact hard ball valve

Most of the valves in the pipe network system are mainly used to cut off and regulate the medium. These valves account for a large proportion in the whole system, have a large amount of consumption, and require the valves to be durable and cost-effective. At the same time, they should be able to adjust and cut off the medium when the medium is in forward flow, and prevent the medium backflow when the pressure difference is changed or repaired, that is, it has the function of two-way cut-off.

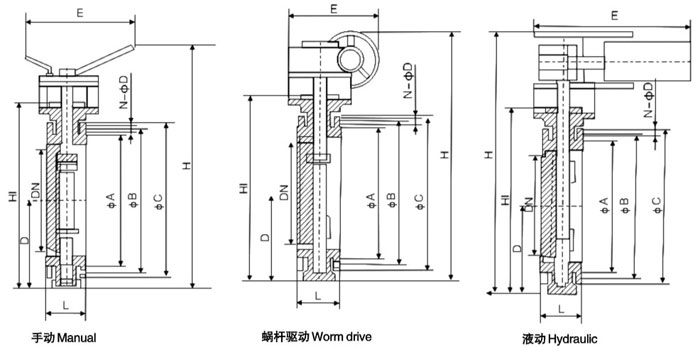

1. Main types: the main types of the valve are: worm gear, electric, pneumatic, hydraulic, among which pneumatic valve and hydraulic valve are suitable for occasions with pressure air source and pressure liquid source.

2. Working principle: the sealing surface of valve core is cubic curved surface, and the sealing surface of valve seat is conic surface. At the sealing point, the seat surface is actually the section of the valve core cubic curved surface (see Figure), so its combination is perfect. It has the function of adaptation (automatic center positioning and overlapping) and compensation for wear. Since the rotation center deviates from the geometric center of the valve core, the actual effect of the spool body is constantly backward and inward when the valve core is opened, and the valve core body is constantly advancing and expanding outward when the valve core is closed. Its function is equivalent to the synthesis of half ball valve, gate valve, globe valve and butterfly valve. Open the diagram of different angles: the main function of the two-way flow valve is that it can not only seal well under the positive pressure, but also seal well when the reverse pressure or the reverse pressure is greater than the positive pressure. When the positive pressure acts, the medium pressure pushes the valve plate to move forward and the valve stem deforms. The sealing surface of the valve plate is close to the sealing surface of the valve seat to transmit pressure, which pushes the valve seat to the valve body step to make it well sealed. When the reverse pressure acts, the medium pressure pushes the valve plate to move backward, and the valve stem deforms. At the same time, the medium pressure pushes the sealing surface of the valve seat close to the sealing surface of the valve plate, transmitting pressure, and pushing the valve seat to the limit deformation position of the valve rod, so as to make it well sealed.

| Driving mode of double flow hard impact hard ball valve | ||||

| Code name |

3 |

6 |

7 |

9 |

| Driving mode | Worm gear | Pneumatic | Hydrodynamics | Electric |

| Connection type of double flow hard impact hard ball valve | |

| Code name |

4 |

| Connection type | flange |

| Sealing surface material of double flow hard impact ball valve | |||

| Code name |

H |

R |

Y |

| Sealing surface material | Martensitic stainless steel | austenitic stainless steel | Cemented carbide |

| Nominal pressure of double flow hard impact ball valve | |||||

| Code name |

6 |

10 |

16 |

25 |

40 |

|

Nominal pressure(MPa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

| Shell material of hard impact ball valve with two-way flow | ||||||

| Code name |

Z |

Q |

C |

I |

P |

R |

| Material Science | Gray cast iron | Ductile iron |

WCB |

1Cr5Mo、ZG1Cr5Mo |

1Cr18Ni9Ti ZG1Cr18Ni9Ti |

1Cr18Ni12MoTi、 ZG1Cr18Ni12MoTi |

| Technical performance specification for two way flow hard impact ball valve | ||||||

|

Nominal diameter(mm) |

Nominal pressure(MPa) |

Test pressure(MPa) |

Applicable temperature(℃) |

Applicable media | ||

|

Shell strength test

|

Forward sealing test | Reverse sealing test | ||||

|

DN50~500 |

1.0 |

1.5 |

1.1 |

1.1 |

If it is not specified as below 80 ℃, it can be produced below 200 ℃ | Water, sewage, oil, etc |

|

|

|

|

|

| Pressure test standard |

GB/T13927-1992 |

General purpose valve pressure test |

|

JB/T9092-1999 |

Test and inspection of valves | |

| Structural design criteria |

GB/T12237-1989 |

General purpose valves flanged and butt welded steel ball valves |

|

GB/T12238-1989 |

General purpose valve flange and wafer connection butterfly valve | |

| Standard of materials used |

GB/T12226-1989 |

Technical specification of gray iron castings for general purpose valves |

|

GB/12227-1989 |

Technical conditions of ductile iron for general purpose valves | |

|

GB/T12229-1989 |

Technical conditions of ductile iron for general purpose valves | |

|

GB/T12230-1989 |

Technical specification of austenitic steel castings for general purpose valves |

| Materials of main parts of double flow hard impact ball valve | |

| Part name | |

| valve body | Gray cast iron, ductile iron, WCB, carbon steel |

| Valve plate |

WCB、Q235、stainless steel |

| Stem | stainless steel |

| valve seat |

WCB、Q235、stainless steel |

| model |

GWXDF204 |

GWXDF3204 |

GWXDF7204 |

GWXDF9204 |

GWXDF6204 |

| Parameter table of electric actuator for two way flow hard impact ball valve | ||||||

|

Nominal diameter of valve(mm) |

Model and specification of electric actuator |

Zui large control turn(Nm) |

Zui large control turn(Nm) |

Output speed(r/min) |

Motor power(kw) |

Motor locked rotor current(A) |

|

50 |

SMR-10 |

100 |

18 |

0.25 |

7.21 |

|

|

65 |

SMR-10 |

100 |

18 |

0.25 |

7.21 |

|

|

80 |

SMR-20 |

200 |

18 |

0.55 |

15.4 |

|

|

100 |

SMR-20 |

200 |

18 |

0.55 |

15.4 |

|

|

125 |

SMR-40 |

300 |

18 |

0.75 |

18.34 |

|

|

150 |

SMR-40 |

450 |

18 |

1.1 |

28.00 |

|

|

200 |

SMR-60 |

450 |

18 |

1.1 |

28.00 |

|

|

250 |

SMR-100 |

900 |

18 |

2.2 |

36.75 |

|

|

300 |

SMR-100 |

900 |

18 |

2.2 |

36.75 |

|

|

350 |

Z120-18 |

1200 |

18 |

3.0 |

55.30 |

|

|

400 |

Z250-18 |

2500 |

18 |

5.5 |

84.35 |

|

|

450 |

Z350-10 |

3500 |

10 |

4.0 |

62.09 |

|

|

500 |

Z500-10 |

5000 |

10 |

5.5 |

84.35 |

|

|

600 |

Q600-0.5 |

6000 |

0.5 |

0.75 |

18.34 |

|

700 |

Q800-0.5 |

8000 |

0.5 |

1.1 |

28.00 |

|

800 |

Q1200-0.5 |

12000 |

0.5 |

1.5 |

28.14 |

|

900 |

Q1600-0.5 |

16000 |

0.5 |

2.2 |

36.75 |

|

1000 |

Q2000-0.5 |

20000 |

0.5 |

3.0 |

55.30 |

|

1200 |

Q3000-0.5 |

30000 |

0.5 |

4.0 |

62.09 |

|

1400 |

Q4000-0.5 |

40000 |

0.5 |

4.0 |

62.09 |

|

1600 |

Q6300-0.25 |

63000 |

0.25 |

5.5 |

84.35 |

|

1800 |

Q8000-0.25 |

80000 |

0.25 |

5.5 |

84.35 |

|

2000 |

Q12000-0.125 |

120000 |

0.125 |

5.5 |

84.35 |

| Installation dimension table of two way flow hard impact ball valve | ||||||||||||||

|

DiameterDN |

A |

B |

C |

D |

E |

H |

L |

N__Фd |

||||||

|

|

|

|

|

|

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | Clip on type | Flange type | Clip on type | Flange type |

|

50 |

88 |

110 |

140 |

112 |

200 |

245 |

255 |

350 |

625 |

530 |

43 |

108 |

4-14 |

4-14 |

|

65 |

108 |

130 |

160 |

115 |

200 |

245 |

255 |

370 |

625 |

530 |

46 |

112 |

4-14 |

4-14 |

|

80 |

124 |

150 |

190 |

120 |

200 |

245 |

255 |

380 |

645 |

565 |

64 |

114 |

4-18 |

4-18 |

|

100 |

144 |

170 |

210 |

138 |

200 |

355 |

255 |

420 |

675 |

600 |

64 |

127 |

4-18 |

4-18 |

|

125 |

174 |

200 |

240 |

164 |

200 |

355 |

255 |

460 |

715 |

640 |

70 |

140 |

4-18 |

8-18 |

|

150 |

199 |

225 |

265 |

175 |

280 |

355 |

315 |

55 |

800 |

705 |

76 |

140 |

4-18 |

8-18 |

|

200 |

254 |

280 |

320 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

89 |

152 |

4-18 |

8-18 |

|

250 |

309 |

335 |

375 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

114 |

165 |

4-18 |

12-18 |

|

300 |

363 |

395 |

440 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

114 |

178 |

4-22 |

12-22 |

|

350 |

413 |

445 |

490 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

127 |

190 |

4-22 |

12-22 |

|

400 |

463 |

495 |

540 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

140 |

216 |

4-22 |

16-22 |

|

450 |

518 |

550 |

595 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

152 |

222 |

4-22 |

16-22 |

|

500 |

568 |

600 |

645 |

380 |

580 |

650 |

714 |

1305 |

1290 |

1415 |

152 |

229 |

4-22 |

20-22 |

|

600 |

667 |

705 |

755 |

450 |

660 |

850 |

810 |

1340 |

1455 |

1605 |

178 |

|

700 |

772 |

810 |

860 |

480 |

550 |

850 |

810 |

1520 |

1585 |

1844 |

229 |

|

800 |

878 |

920 |

975 |

530 |

550 |

1250 |

810 |

1710 |

1700 |

2040 |

241 |

|

900 |

978 |

1020 |

1075 |

580 |

550 |

1250 |

863 |

1810 |

1965 |

2255 |

241 |

|

1000 |

1078 |

1120 |

1175 |

650 |

750 |

1250 |

863 |

1960 |

2015 |

2380 |

300 |

| Technical performance specification for two way flow hard impact ball valve | ||||||

|

Nominal diameter(mm) |

Nominal pressure(Mpa) |

Test pressure(Mpa) |

Applicable temperature(℃) |

Applicable media | ||

| Shell strength test | Forward sealing test | Reverse sealing test | ||||

|

DN50~3000mm |

0.6 |

0.9 |

0.66 |

0.66 |

If not indicated as 0 ~ 80 ℃, 0 ~ 200 ℃ can be produced | |

|

1.0 |

1.5 |

1.1 |

1.1 |

|||

|

1.6 |

2.4 |

1.76 |

1.76 |

|||

|

2.5 |

3.75 |

2.76 |

2.76 |

|||

|

4.0 |

6.0 |

4.4 |

4.4 |

|||

| Main design and manufacturing standards of double flow hard impact ball valve | ||

| Standard content | Standard number | Standard name |

| Flange standard |

GB/T9113-2000 |

Integral steel pipe flange |

|

GB/T17241.6-1998 |

Integral cast iron pipe flange | |

| Structural length standard |

GB/T1221-2005 |

Structural length of metal valve |

| Pressure test standard |

GB/T13927-1992 |

General purpose valve pressure test |

|

JB/T9092-1999 |

Test and inspection of valves | |

| Structural design criteria |

GB/T12237-1989 |

General purpose valves flanged and butt welded steel ball valves |

|

GB/T12238-1989 |

General purpose valve flange and wafer connection butterfly valve | |

| Standard of materials used |

GB/T12226-1989 |

Standard of materials used |

|

GB/12227-1989 |

Standard of materials used | |

|

GB/T12229-1989 |

Standard of materials used | |

| Technical specification of austenitic steel castings for general purpose valves |

| Materials of main parts of double flow hard impact ball valve | |

| Part name | |

| valve body | Gray cast iron, ductile iron, WCB, carbon steel |

| Valve plate |

WCB、Q235、stainless steel |

| Stem | stainless steel |

| valve seat | stainless steel |

| Driving mode of double flow hard impact hard ball valve | |||||

| Driving mode | Manual | worm | Hydrodynamics | Electric | Pneumatic |

| model |

GWXDF207 |

GWXDF3207 |

GWXDF7207 |

GWXDF9207 |

GWXDF6207 |

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website