Telephone:

0577-67975099

Location:Home > Product Center > Globe Valve > CARXICARHISeries compound exhaust valve

Location:Home > Product Center > Globe Valve > CARXICARHISeries compound exhaust valve

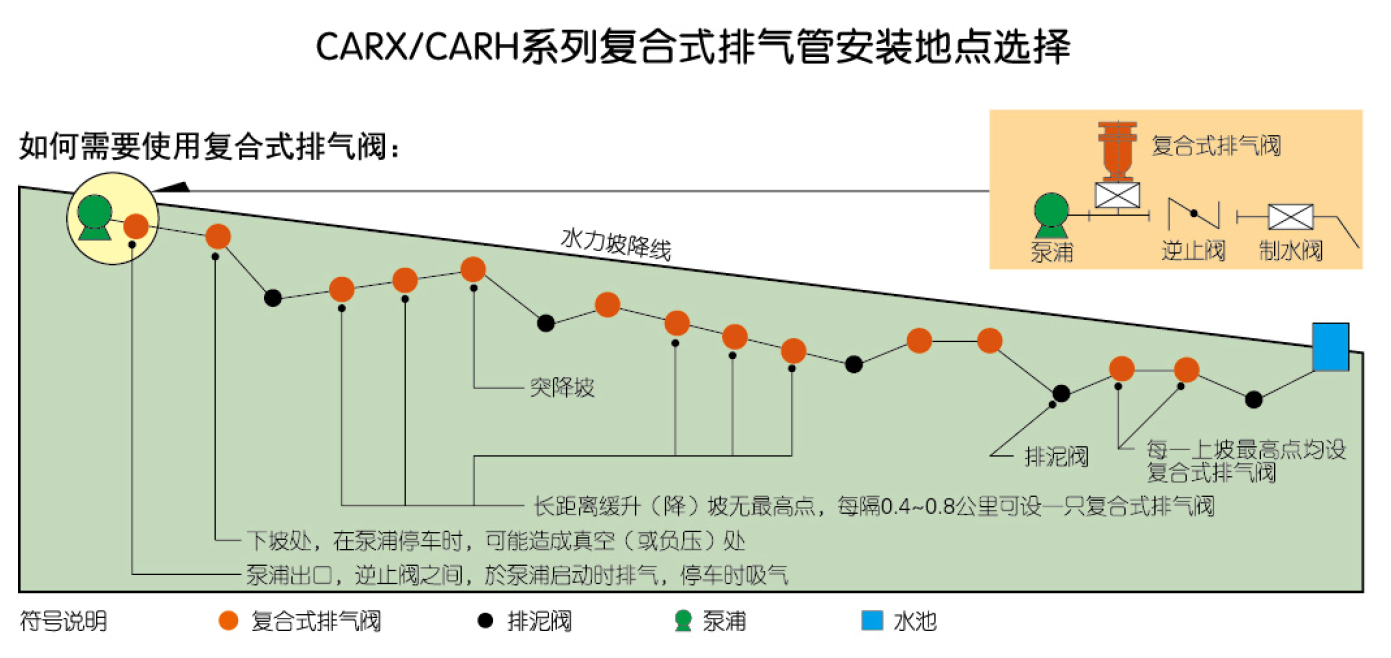

The compound exhaust valve is suitable to be installed at the water outlet of the water pump or in the water supply and distribution pipeline to remove a large amount of accumulated air in the pipeline. At the same time, the micro air accumulated in the higher part of the pipeline is discharged to the atmosphere, so as to improve the efficiency of the pipeline and water pump. Once there is negative pressure in the pipe, this series of valves can quickly inhale the outside air to avoid the pipe breaking caused by negative pressure The occurrence of.

This series of compound exhaust valve is suitable for installation at the water outlet of water pump or in the water supply and distribution pipeline, so as to eliminate a large amount of accumulated air in the pipeline. At the same time, the micro air accumulated at the higher place of the pipeline is discharged into the atmosphere to improve the use efficiency of the pipeline and water pump. In case of negative pressure in the pipe, this series of valve can quickly inhale the external air to avoid the pipeline breaking due to negative pressure The occurrence of tube phenomenon.

Among them, the carh waterproof hammer type exhaust valve is equipped with upper slow closing device on the basis of the original carx type, which is more suitable for the conditions of long-distance water delivery, large fluctuation of pipeline direction, easy to produce cut-off closure and water column separation.

| Air closing pressure Mpa | |

| Water closing pressure Mpa |

≤0.02 |

| Valve body test pressure Mpa |

1.5Multiple nominal pressure |

| MPA sealing pressure test |

1.1Multiple nominal pressure |

| Starting pressure of carh buffer MPa |

≥0.1 |

| Valve manufacturing standard |

accord withCJ/T217-2005及 Enterprise standardQ/IDIK09-2011 |

| Flange standard |

accord withGB/T17241.6-2008 |

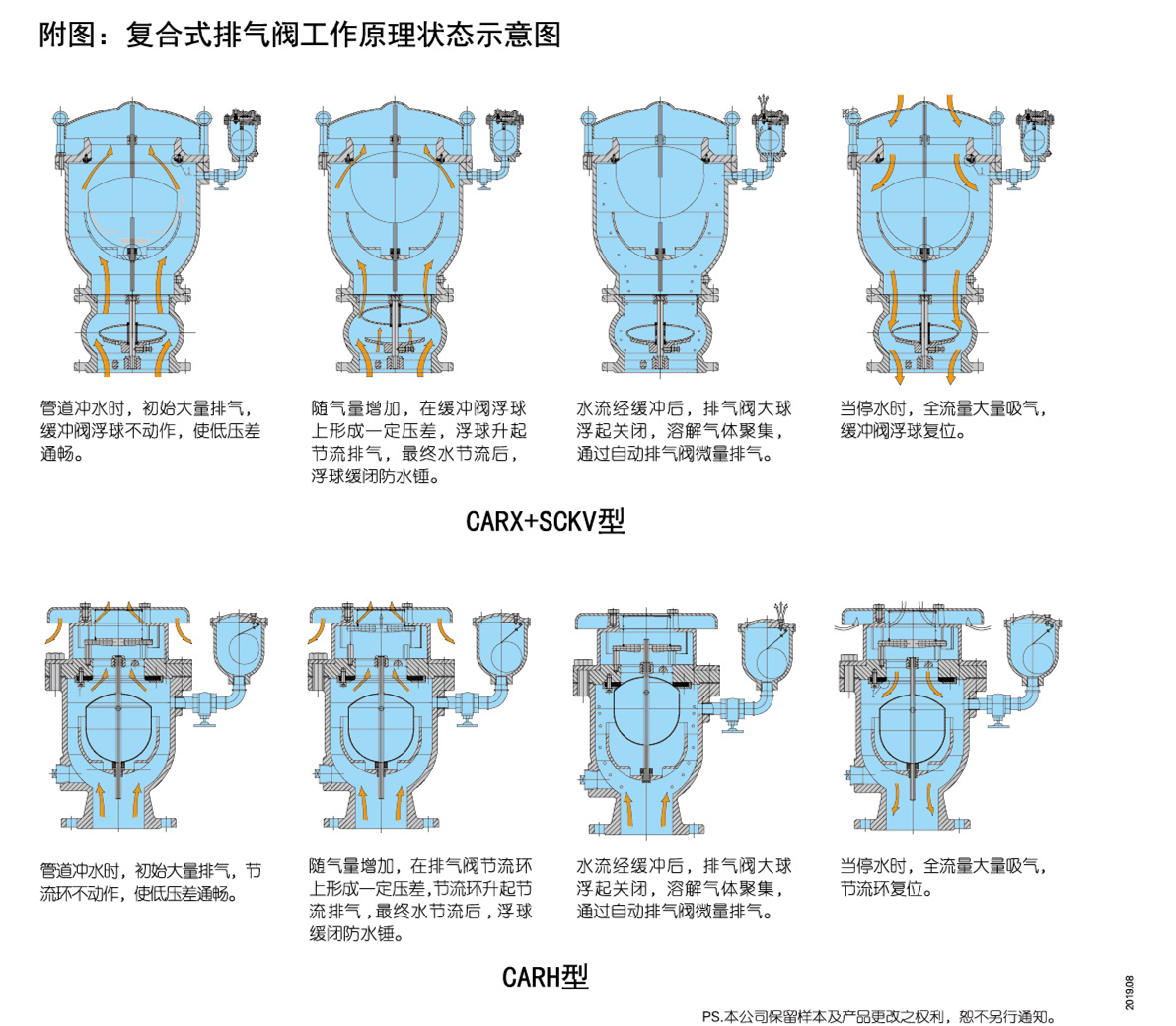

When water is injected into the water pipe, the piston or floating ball stays in the open position to exhaust a large amount of gas. When the air is exhausted, there is water in the valve and the floating ball is floated. When the piston or floating ball reaches the closed position, a large amount of exhaust is stopped. When the water in the pipe is normally transported, if a small amount of air accumulates in the valve to a certain extent, the water level in the valve will drop, and the floating ball will drop accordingly. At this time, a small amount of air will be discharged from the micro exhaust hole (integral type) or from the exhaust hole of automatic exhaust valve (split type). When the water pump stops, the water flow in the pipe is empty or negative pressure is generated in the pipe, the piston opens quickly to inhale air to ensure the safety of the pipeline.

When water is injected into the water pipe, the piston or floating ball stays in the open position to exhaust a large amount of gas. When the air is exhausted, there is water in the valve and the floating ball is floated. When the piston or floating ball reaches the closed position, a large amount of exhaust is stopped. When the water in the pipe is normally transported, if a small amount of air accumulates in the valve to a certain extent, the water level in the valve will drop, and the floating ball will drop accordingly. At this time, a small amount of air will be discharged from the micro exhaust hole (integral type) or from the exhaust hole of automatic exhaust valve (split type). When the water pump stops, the water flow in the pipe is empty or negative pressure is generated in the pipe, the piston opens quickly to inhale air to ensure the safety of the pipeline.

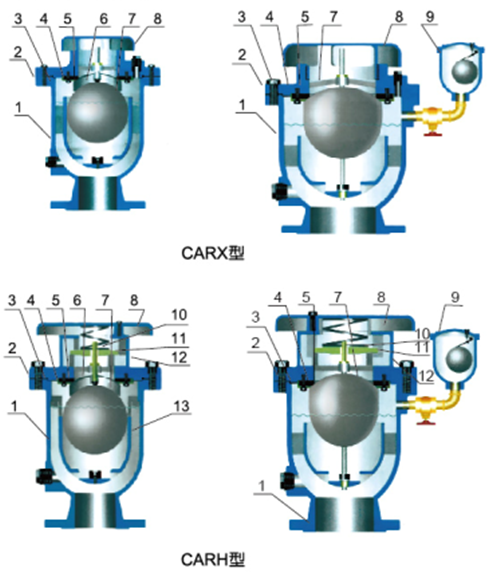

CARX+SCKV/CARHSee the attached figure for the working principle state diagram of the composite exhaust valve (see the back cover page).

| Serial number | name | texture of material |

|

1 |

valve body |

Ductile iron(OT450-10) |

|

2 |

Valve cover |

Ductile iron(QT450-10) |

|

3 |

O-ring |

Nitrile rubber(NBR) |

|

4 |

Piston frame |

Aluminum bronze(ZCuAl10Fe3) |

|

5 |

Sealing ring |

Nitrile rubber(NBR) |

|

6 |

piston |

stainless steel(0Cr19Ni9 |

|

7 |

Floating ball |

stainless steel(0Cr19Ni9) |

|

8 |

Exhaust hood |

Ductile iron(QT450-10)/carbon steel(Q235-A) |

|

9 |

Automatic exhaust valve | |

|

10 |

Spring |

stainless steel(1Cr18Ni9) |

|

11 |

Throttle ring | polypropylene |

|

12 |

Buffer cover |

Ductile iron(QT450-10) |

|

13 |

Inner cylinder of valve body | polypropylene |

CARX/CARH系列复合式排气阀(清水用)

Pressure rating: PN1.0 / 1.6/2.5mpa

Nominal diameter: DN25 ~ dn80mm

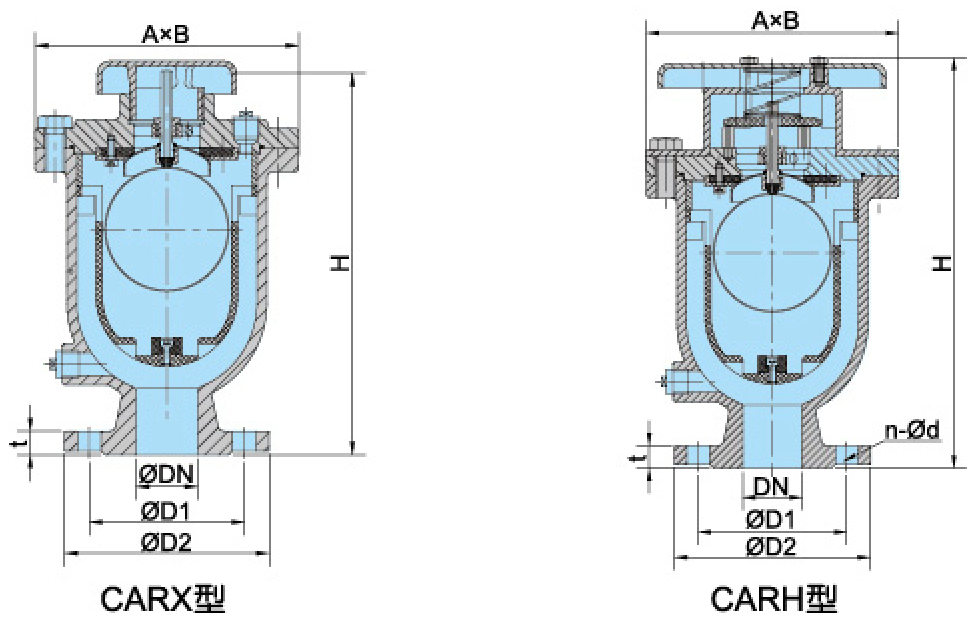

Integral type: (DN25 is threaded type, the rest are flange type)

Dimensions:

|

Nominal diameter DN |

Product code |

PN(MPa) |

D1 |

D2 |

t |

n-d |

H |

A×B |

|

|

CARX |

CARH |

||||||||

|

25 |

CARX-0025 |

1.0/1.6/2.5 |

ZG1" |

/ |

/ |

/ |

~260 |

/ |

145×145 |

|

50 |

CARX(H)-0050 |

1.0/1.6/2.5 |

125 |

165 |

19 |

4-19 |

~320 |

~346 |

162×162 |

|

80 |

CARX(H)-0080 |

1.0/1.6/2.5 |

160 |

200 |

19 |

4-19 |

~365 |

~407 |

198×198 |

Pressure rating: PN1.0 / 1.6/2.5mpa

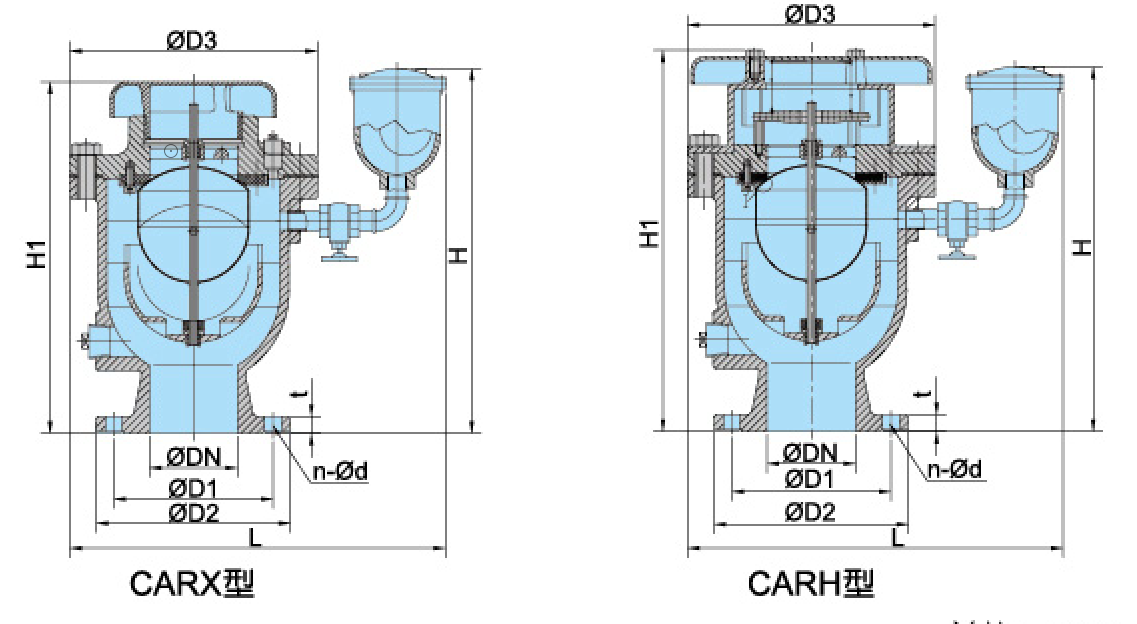

Nominal diameter: DN 100 ~ dn400mm

Split type: (for the description of automatic exhaust valve, please refer to relevant samples of our company)

Dimensions: Units:mm

|

Nominal diameterDN |

Product code |

PN (MPa) |

D1 |

D2 |

t |

n-d |

H |

H1 |

L |

D3 |

||

|

CARX |

CARH |

CARX |

CARH |

|||||||||

|

100 |

CARX(H)-0100 |

1.0/1.6 |

180 |

220 |

19 |

8 |

~413 |

~413 |

~398 |

~432 |

425 |

280 |

|

2.5 |

190 |

235 |

19 |

8 |

||||||||

|

150 |

CARX(H)-0150 |

1.0/1.6 |

240 |

285 |

19 |

8 |

~447 |

~460 |

~445 |

~511 |

505 |

356 |

|

2.5 |

250 |

300 |

20 |

8 |

||||||||

|

200 |

CARX(H)-0200 |

1.0 |

295 |

340 |

20 |

8 |

~563 |

~547 |

~546 |

~673 |

581 |

446 |

|

1.6 |

295 |

340 |

20 |

12 |

||||||||

|

2.5 |

310 |

360 |

22 |

12 |

||||||||

|

*250 |

CARX(H)-0250 |

1.0 |

350 |

395 |

22 |

12 |

~787 |

~766 |

~685 |

~900 |

880 |

500 |

|

1.6 |

355 |

405 |

22 |

12 |

||||||||

|

2.5 |

370 |

425 |

24.5 |

12 |

||||||||

|

300 |

CARX(H)-0300 |

1.0 |

400 |

445 |

24.5 |

12 |

~870 |

~850 |

~790 |

~1035 |

905 |

605 |

|

1.6 |

410 |

460 |

24.5 |

12 |

||||||||

|

2.5 |

430 |

485 |

27.5 |

16 |

||||||||

|

*400 |

CARX(H)-0400 |

1.0 |

515 |

565 |

24.5 |

16 |

~893 |

~906 |

~935 |

~1210 |

991 |

740 |

|

1.6 |

525 |

580 |

28 |

16 |

||||||||

|

2.5 |

550 |

20 |

19 |

16 |

||||||||

Note: * please consult the technical department of our company before ordering if you need PN2.5MPa.

How to select the diameter of composite exhaust valve:

1. Calculate the maximum exhaust or suction capacity at several higher points in the pipeline.

Calculated by gravity flow:

Where: s -------- slope s = TGA (a pipeline and horizontal inclination angle)

D -------- pipe diameter (mm)

Q -------- exhaust or suction capacity (m2 / h)

How to consider the maximum displacement:

A. When the air pressure difference between the inlet and outlet of the general composite exhaust valve reaches 4psi (i.e. 0.28kg/cm2), the air in the pipe can be finished before the piston is closed. Taking the calculated value of the above formula and 4psi as the reference point, the proper diameter of the exhaust valve can be obtained by checking the performance curve.

B. Generally, when the negative pressure in the pipe is more than 5psi (i.e. 0.35kg/cm2), it is possible to break the pipe. Taking the calculated value of the above formula and 5psi as the reference point and checking the performance curve chart, the appropriate diameter of the exhaust valve can be obtained.

Compare a and B, select the larger diameter, that is, the required exhaust valve diameter.

2. If the pipeline rupture caused by negative pressure is not considered, or the water flow rate in the pipe is between 1.2 and 2.4m/s, the appropriate diameter of exhaust valve can be selected according to the following table (or according to experience, the diameter of exhaust valve can be selected according to 1 / 8 pipe diameter of water delivery pipe).

|

Q(m³/h) |

25 |

50 |

80 |

100 |

150 |

200 |

250 |

300 |

400 |

|

0~350 |

220~740 |

650~1600 |

1300~3100 |

3000~7500 |

7300~15000 |

11000~21000 |

14000~31000 |

27000~59000 |

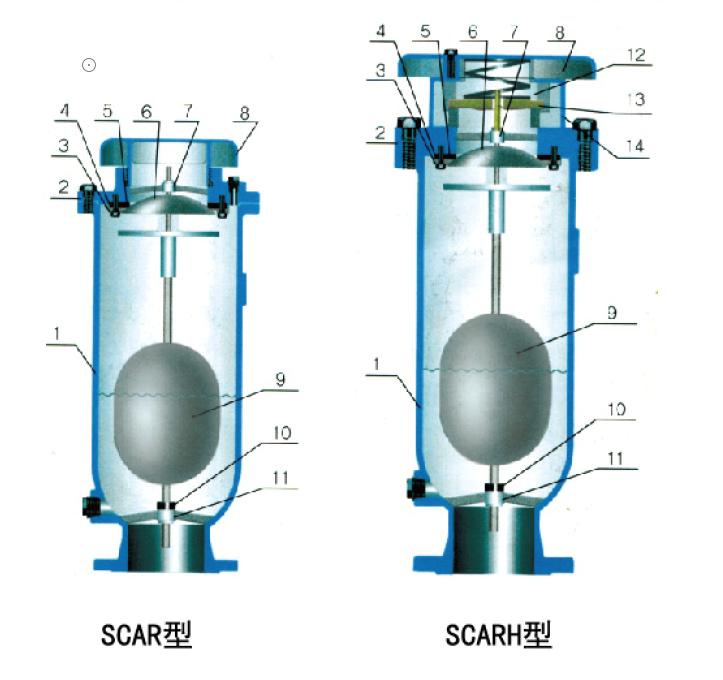

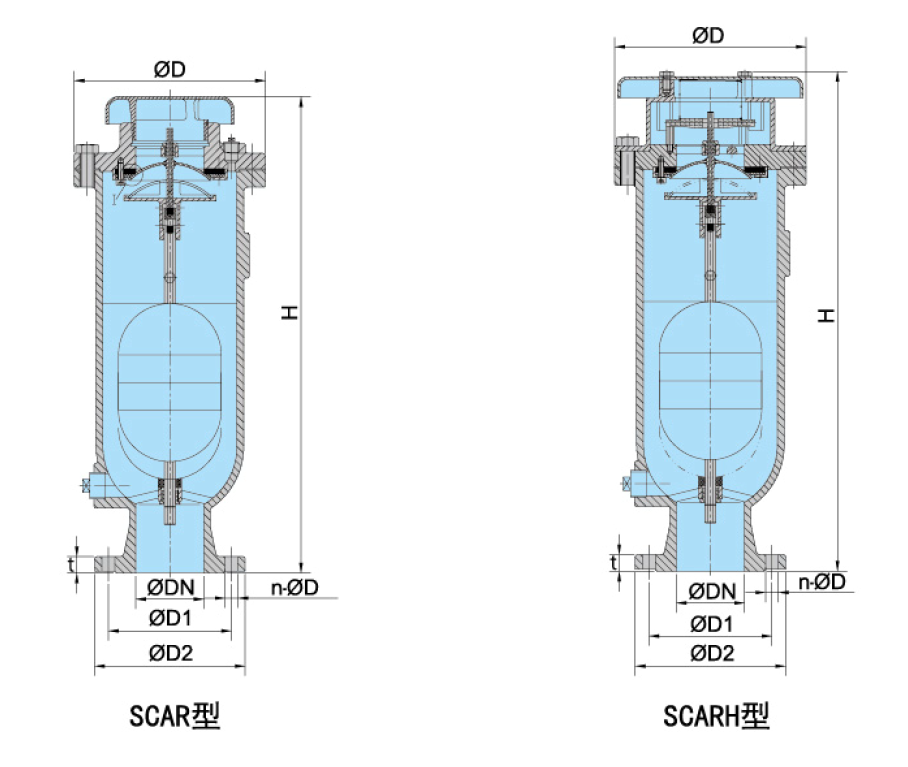

SCARISCARHI)系列污水复合式排气阀

summary:

In addition to the same technical parameters and indexes as carxicarh), considering the characteristics of sewage, the floating ball directly acts on the light spherical piston structure through the top plug, so that the water level of the valve is lowered and the floating impurities are far away from the sealing surface to prevent the dirt from depositing on the sealing surface of the piston.

Scarh water hammer sewage exhaust valve is equipped with upper slow closing device on the basis of the original scar sewage exhaust valve, which is more resistant to water and gas impact, not easy to damage the internals, prevent closing water hammer and make the exhaust function work normally.

Composition of sewage exhaust valve:

| Pressure rating: PN1.0MPa Nominal diameter: dn50-200 mm Scar / scarh |

|

Name and material of main parts:

| Serial number | name | texture of material |

|

name | texture of material | |||

|

1 |

valve body |

Ductile iron(QT450-10) |

8 |

Exhaust hood |

Ductile iron(QT450-10)/carbon steel(Q235-A) |

|||

|

2 |

Valve cover |

Ductile iron(QT450-10)/carbon steel |

9 |

Floating ball | Assembly | |||

| Piston frame | Cast stainless steel |

10 |

Cushion | rubber | ||||

|

4 |

The seal is broken |

NBR standard adhesive(NBR) |

11 |

Guide sleeveB |

stainless steel0Cr19Ni9 |

|||

|

5 |

Limit plate |

stainless steel0Cr19Ni9 |

12 |

Spring |

stainless steel0Cr19Ni9 |

|||

|

6 |

piston |

stainless steel0Cr19Ni9 |

13 |

Throttle ring | ||||

|

7 |

Guide sleeveA |

stainless stee0Cr19Ni9 |

14 |

Buffer cover |

Ductile iron(QT450-10) |

Dimensions

|

Nominal diameterDN |

Product code |

PN(MPa) |

D1 |

D2 |

t |

n-d |

H |

D |

|

|

CARX |

CARH |

||||||||

|

50 |

SCAR(H)-0050 |

1.0 |

125 |

165 |

19 |

4-φ19 |

~528 |

~557 |

162×162 |

|

80 |

SCAR(H)-0080 |

1.0 |

160 |

200 |

19 |

4-φ19 |

~613 |

~655 |

198×198 |

|

100 |

SCAR(H)-0100 |

1.0 |

180 |

220 |

19 |

8-φ19 |

~698 |

~732 |

280 |

|

150 |

SCAR(H)-0150 |

1.0 |

240 |

285 |

19 |

4-φ23 |

~870 |

~929 |

356 |

|

200 |

SCAR(H)-0200 |

1.0 |

295 |

340 |

19 |

8-φ23 |

~1095 |

~1162 |

446 |

Buffer plug valve sckv

Double disc buffer valve DDHC

summary:

Sckv or DDHC series exhaust valve is mainly installed at the inlet of exhaust valve, which is used for sudden pressure and large flow impact during pipeline water supply, to prevent large amount of water spray of exhaust valve and effectively slow down water hammer. Especially for long-distance pipeline, large fluctuation and frequent start-up of water pump and installation of exhaust valve at the outlet of water pump need to be installed. Generally, it is recommended to be used together with the exhaust valve (carh and scarh series have been equipped with upper slow closing device, so it is not necessary to install this buffer valve. See the attached figure on the bottom page for the working principle status diagram).

Technical parameters:

| Technical characteristics | characteristic parameter |

|

|

Nominal diameter(mm |

SCKV:DN25-DN400 DDHC:DN50-DN300 |

|

|

Nominal pressureMPa |

PN1.0/1.6 |

|

|

Shell test pressureMPa |

1.5PN |

|

| Pressure test standard |

accord withGB/T1 3927-2008 |

Part name and material: Dimension:

| Serial number | name | texture of material |

|

|

1 |

Ductile iron | stainless steel | |

|

2 |

Bracket | Ductile iron | |

|

3 |

Cushion | Nitrile rubber | |

|

4 |

Floating bucket | stainless steel | |

|

5 |

valve body | Ductile iron | |

| Floating bucket support | Ductile iron |

|

Nominal diameterDN |

Product code |

PN(MPa) |

D1 |

D2 |

t |

L |

n-d |

|

25 |

CARX(H)-0025 |

1.0/1.6/2.5 |

ZG1" |

47 |

/ |

58 |

/ |

|

50 |

CARX(H)-0050 |

1.0/1.6/2.5 |

125 |

165 |

19 |

102 |

4-φ19 |

|

80 |

CARX(H)-0080 |

1.0/1.6/2.5 |

160 |

200 |

19 |

121 |

8-φ19 |

|

100 |

CARX(H)-0100 |

1.0/1.6 |

180 |

220 |

19 |

146 |

8-φ19 |

|

2.5 |

190 |

235 |

19 |

8-φ23 |

|||

|

150 |

CARX(H)-0150 |

1.0/1.6 |

240 |

285 |

19 |

228 |

8-φ23 |

|

2.5 |

250 |

300 |

20 |

8-φ28 |

|||

|

200 |

CARX(H)-0200 |

1.0 |

295 |

340 |

20 |

258 |

8-φ23 |

|

1.6 |

295 |

340 |

12-φ23 |

||||

|

2.5 |

310 |

360 |

22 |

12-φ28 |

|||

|

250 |

CARX(H)-0250 |

1.0 |

350 |

395 |

22 |

305 |

12-φ23 |

|

1.6 |

355 |

405 |

12-φ28 |

||||

|

2.5 |

370 |

425 |

24.5 |

12-φ31 |

|||

|

300 |

CARX(H)-0300 |

1.0 |

400 |

445 |

24.5 |

320 |

12-φ23 |

|

1.6 |

410 |

460 |

12-φ28 |

||||

|

2.5 |

430 |

485 |

27.5 |

16-φ31 |

|||

|

400 |

CARX(H)-0400 |

1.0 |

515 |

565 |

24.5 |

457 |

16-φ28 |

|

1.6 |

525 |

580 |

28 |

16-φ31 |

|||

|

2.5 |

550 |

20 |

32 |

16-φ37 |

Dimensions: Units:mm

|

Nominal diameterDN |

Product code |

L |

L1 |

D1 |

D2 |

D |

|

50 |

DDHC-0050 |

54 |

6 |

65 |

48 |

105 |

|

65 |

DDHC-0065 |

60 |

10 |

78 |

57 |

124 |

|

80 |

DDHC-0080 |

67 |

10 |

91 |

70 |

137 |

|

100 |

DDHC-0100 |

67 |

20 |

117 |

91 |

162.5 |

|

125 |

DDHC-0125 |

83 |

25 |

144 |

113 |

192.5 |

|

150 |

DDHC-0150 |

95 |

32 |

171 |

135 |

218 |

|

200 |

DDHC-0200 |

127 |

40 |

222 |

176 |

273 |

|

250 |

DDHC-0250 |

140 |

59 |

276 |

222 |

328 |

|

300 |

DDHC-0300 |

181 |

64 |

327 |

270 |

379 |

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website