Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > PQ340H Side mounted eccentric hemisphere valve

Location:Home > Product Center > Ball Valve > PQ340H Side mounted eccentric hemisphere valve

PQ340H The structure design of the side mounted eccentric hemisphere valve is similar to that of the three eccentric hard seal butterfly valve. The ball valve has the advantages of easy operation, no friction during opening, zero leakage and long service life. In addition, the valve can continue to be used by adjusting or replacing the sealing pair, which avoids the disadvantages of scrapping the whole set of valves due to sealing failure and saves cost.

The structure design of the side mounted eccentric hemisphere valve is similar to that of the three eccentric hard seal butterfly valve. The ball valve has the advantages of easy operation, no friction during opening, zero leakage and long service life. In addition, the valve can continue to be used by adjusting or replacing the sealing pair, which avoids the disadvantages of scrapping the whole set of valves due to sealing failure and saves cost.

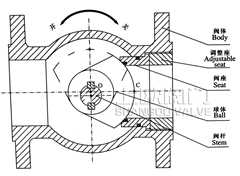

The actuator (or wrench) drives the valve stem to force the ball of the closing part to rotate around the center a, and the ball moves from point B to point C. relative to the center point O of the valve, the trajectory from B to C is a cam like eccentricity. When the valve is turned right into the valve seat, the valve is closed and keeps good sealing. According to the cam principle, the force acting on the valve seat increases gradually from the opening to the closing of the valve The surface of the closing part is separated from the valve seat completely, and the sealing specific pressure is gradually increased until it is completely sealed, otherwise, it is open. See the figure below:

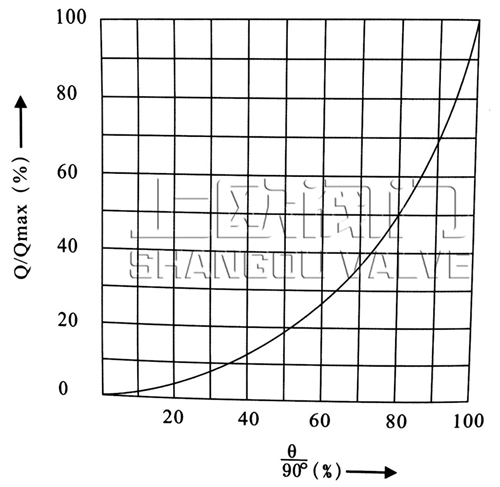

Working principle diagram Equal percentage flow curve

1: The outer step of the valve seat is matched with the inner step of the valve body to prevent the ball and the valve seat from jamming or detaching;

2: When the eccentric valve body, eccentric ball, valve seat and valve rod are placed without movement, they are automatically centered in the common track, and the closer they are closed, the better the sealing performance is. Therefore, the sealing performance of the eccentric hemispherical valve is safe and reliable. When the valve is opened and closed, the ball and valve seat are completely separated. It eliminates the wear of the seal and overcomes the problem that the valve seat and the sealing surface of the traditional ball valve always wear

3: The non-metallic elastic material is embedded in the metal seat, and the metal sealing surface of the valve seat is well protected;

4: When the valve is fully open, the flow capacity is large, the pressure loss is small, and the medium will not deposit in the valve body;

5: Long service life, wear-resistant sealing pair, and compensation, valve seat can be adjusted or replaced.

Hemispherical valve products are divided into six series according to their applications: general valve, pipeline valve, slurry valve, gas valve, Petrochemical valve and pulverized coal injection valve. In petroleum, chemical industry, metallurgy, electric power, gas, ash discharge, coal powder injection and other industries, it is the replacement product of gate valve, globe valve, Y-type valve and ball valve.

Nominal diameter: dn50-1000 nominal pressure: pn1.0-10.0mpa

Valve body: WCB CF8 CF8M zg1cr18ni9ti

Ball: hard seal: zg1cr18ni9ti soft seal: CF8 / CF8M

Valve seat: hard seal: 2Cr13, 1Cr18Ni9Ti, soft seal: PTFE ppl

Working temperature: hard seal: - 40 ~ 425 ℃, soft seal: - 28 ~ 250 ℃

The design and manufacture are in accordance with API6D GB / t12237-1989

Test and inspection shall be in accordance with ap1598 JB / t9092-1999

Flange size GB / t9113-2000 JB / t79-1994 hg20592-1997

The structural length is as per kyv-2000

| Nominal pressure | Maximum working pressure at normal temperature | Shell test pressure | Test pressure of airtight seal | High pressure seal test pressure |

| 1.6 | 1.6 | 2.4 | 0.6 | 1.76 |

| 2.5 | 2.5 | 3.8 | 0.6 | 2.75 |

| 4.0 | 4.0 | 6.0 | 0.6 | 4.4 |

| 6.4 | 6.4 | 9.6 | 0.6 | 7.1 |

| Class150 | 2.0 | 3.0 | 0.6 | 2.2 |

| Class300 | 5.0 | 7.5 | 0.6 | 5.5 |

| Shell material | Seat material | Suitable temperature | Applicable media |

| type | stainless steel | ≤150℃ | Water and steam Oil products, etc |

| stainless steel |

≤250℃ | ||

| type | stainless steel | ≤150℃ | Nitric acid |

| stainless steel | ≤200℃ | ||

| type | stainless steel | ≤150℃ | Acetic acid |

| stainless steel |

≤200℃ | ||

| type | Cemented carbide | ≤550℃ | Steam, metallurgy Refining and energy |

| Body cover | GB | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12MoTi | ZG15Cr1Mo1v | |||

| ASTM | WCB | CF8 | CF8M | WC9 | ||||

| sphere | GB | ZG2Cr13 | ZG1Cr18Ni9Ti/ Special surface treatment |

ZG0Cr18Ni12MoTi Special surface treatment |

ZG15Cr1Mo1v Special surface treatment |

|||

| ASTM | CA15 | CF8+HF | CF8+HF | WC9+HF | ||||

| Stem | GB | 2Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12MoTi | 25Cr2Mo2v | |||

| ASTM | 420 | 304 | 316 | F22a | ||||

| valve seat | GB | PTFE | 2Cr13 | PTFE | 1Cr18Ni9Ti | PTFE | 0Cr18Ni12MoTi | D517 |

| ASTM | PTFE | 420 | PTFE | 304 | PTFE | 316 | HF | |

| filler | GB | PTFE | Flexible graphite | PTFE | Flexible graphite | PTFE | Flexible graphite | Flexible graphite |

| ASTM | PTFE | Flexible graphite | PTFE | Flexible graphite | PTFE | Flexible graphite | ||

| Bolt | GB | 25 | 0Cr18Ni9 | 0Cr18Ni9 | 15Cr1Mo1v | |||

| ASTM | A193 B7 | A320-B8 | A320-B8 | A193 B16 | ||||

| Nut | GB | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 20CrMo | |||

| ASTM | A194 2H | A194-8 | A194-8 | A194-4 | ||||

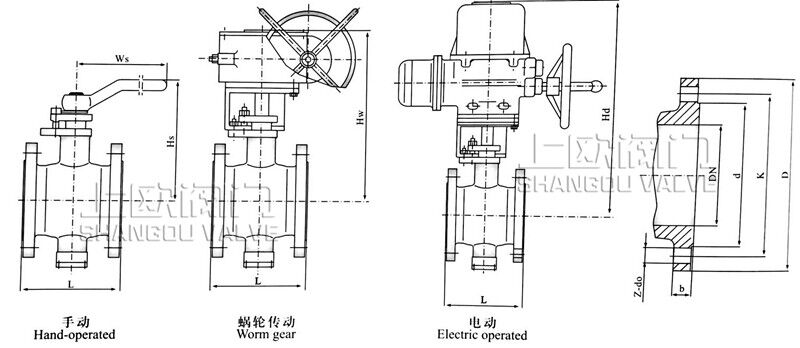

| Nominal pressurePN | Nominal diameterDN | size(mm)Dimensions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | D | K | d | Y | b | Z-Φdo | Ws | Hs | Hw | Hd | ||

| 1.6MPa | 50 | 124 | 165 | 125 | 100 | - | 16 | 4-Φ18 | 230 | 164 | 260 | 310 |

| 65 | 145 | 185 | 145 | 120 | - | 18 | 4-Φ18 | 250 | 180 | 275 | 330 | |

| 80 | 165 | 200 | 160 | 135 | - | 20 | 8-Φ18 | 300 | 200 | 300 | 360 | |

| 100 | 194 | 220 | 180 | 155 | - | 20 | 8-Φ18 | 320 | 235 | 335 | 390 | |

| 125 | 210 | 250 | 210 | 185 | - | 22 | 8-Φ18 | 400 | 260 | 335 | 405 | |

| 150 | 229 | 285 | 240 | 210 | - | 24 | 8-Φ23 | 500 | 280 | 375 | 440 | |

| 200 | 243 | 340 | 295 | 265 | - | 26 | 12-Φ23 | 800 | 320 | 410 | 470 | |

| 250 | 297 | 405 | 355 | 320 | - | 30 | 12-Φ25 | 100 | 355 | 485 | 550 | |

| 300 | 338 | 460 | 410 | 375 | - | 30 | 12-Φ25 | 1200 | 400 | 530 | 595 | |

| 350 | 400 | 520 | 470 | 435 | - | 34 | 16-Φ25 | - | - | 580 | 650 | |

| 400 | 400 | 580 | 525 | 485 | - | 36 | 16-Φ30 | - | - | 650 | 730 | |

| 450 | 502 | 640 | 585 | 545 | - | 40 | 20-Φ30 | - | - | 710 | 790 | |

| 500 | 533 | 715 | 650 | 608 | - | 44 | 20-Φ34 | - | - | 760 | 840 | |

| 600 | 686 | 840 | 770 | 718 | - | 48 | 20-Φ41 | - | - | 870 | 960 | |

| 700 | 762 | 910 | 840 | 788 | - | 50 | 24-Φ41 | - | - | 910 | 1080 | |

| 800 | 864 | 1025 | 950 | 898 | - | 52 | 24-Φ41 | - | - | 935 | 1125 | |

| 900 | 914 | 1125 | 1050 | 998 | - | 54 | 28-Φ41 | - | - | 995 | 1255 | |

| 1000 | 1255 | 1170 | 1110 | - | 56 | 28-Φ48 | - | - | 1080 | 1385 | ||

| 1200 | 1485 | 1390 | 1325 | - | 58 | 32-Φ54 | - | - | 1175 | 1490 | ||

| 1400 | 1685 | 1590 | 1525 | - | 60 | 36-Φ54 | - | - | 1280 | 1565 | ||

| 2.5MP | 50 | 124 | 165 | 125 | 100 | - | 20 | 4-Φ18 | 230 | 164 | 260 | 310 |

| 65 | 145 | 185 | 145 | 120 | - | 22 | 8-Φ18 | 250 | 180 | 275 | 330 | |

| 80 | 165 | 200 | 160 | 135 | - | 22 | 8-Φ18 | 300 | 200 | 300 | 360 | |

| 100 | 194 | 230 | 190 | 160 | - | 24 | 8-Φ23 | 320 | 235 | 335 | 390 | |

| 125 | 210 | 270 | 220 | 188 | - | 28 | 8-Φ25 | 400 | 260 | 355 | 405 | |

| 150 | 229 | 300 | 250 | 218 | - | 30 | 8-Φ25 | 500 | 280 | 375 | 440 | |

| 200 | 243 | 360 | 310 | 278 | - | 34 | 12-Φ25 | 800 | 320 | 410 | 470 | |

| 250 | 297 | 425 | 370 | 332 | - | 36 | 12-Φ30 | 1000 | 355 | 485 | 550 | |

| 300 | 338 | 485 | 430 | 390 | - | 40 | 16-Φ30 | 1200 | 400 | 530 | 595 | |

| 350 | 400 | 555 | 490 | 448 | - | 44 | 16-Φ34 | - | - | 580 | 650 | |

| 400 | 400 | 620 | 550 | 505 | - | 48 | 16-Φ34 | - | - | 650 | 730 | |

| 450 | 502 | 670 | 600 | 555 | - | 50 | 20-Φ34 | - | - | 710 | 790 | |

| 500 | 533 | 730 | 660 | 610 | - | 52 | 20-Φ41 | - | - | 760 | 840 | |

| 600 | 686 | 845 | 770 | 718 | - | 56 | 20-Φ41 | - | - | 870 | 960 | |

| 700 | 762 | 960 | 875 | 815 | - | 60 | 24-Φ48 | - | - | 990 | 1080 | |

| 800 | 864 | 1085 | 990 | 930 | - | 64 | 24-Φ48 | - | - | 935 | 1125 | |

| 900 | 914 | 1185 | 1090 | 1025 | - | 66 | 28-Φ54 | - | - | 995 | 1255 | |

| 1000 | 1320 | 1210 | 1140 | - | 68 | 28-Φ58 | - | - | 1080 | 1385 | ||

| 1200 | 1520 | 1420 | 1350 | - | 72 | 32-Φ58 | - | - | 1175 | 1490 | ||

| 1400 | 1755 | 1640 | 1560 | - | 78 | 36-Φ65 | - | - | 1280 | 1565 | ||

Note: due to the limitation of the number of words in the webpage, many sizes cannot be listed. If you have any requirements, please contact us at any time

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website