Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > Top mounted ball valve DYQ340F/HY-16C/P

Location:Home > Product Center > Ball Valve > Top mounted ball valve DYQ340F/HY-16C/P

In the process of valve body closing, the more eccentric and the valve seat are closed together, the better the valve body can be closed automatically by eccentric and centering ball. The ball and valve seat of the valve are completely separated, which eliminates the wear of the sealing ring and overcomes the problem that the traditional ball valve seat and the sealing surface of the ball are always worn. The non-metallic elastic material is embedded in the metal seat, and the metal surface of the valve seat is well protected. This product is especially suitable for steel industry, aluminum industry, fiber, small solid particles, pulp, coal ash, petroleum gas and other media.

In the process of valve body closing, the more eccentric and the valve seat are closed together, the better the valve body can be closed automatically by eccentric and centering ball. The ball and valve seat of the valve are completely separated, which eliminates the wear of the sealing ring and overcomes the problem that the traditional ball valve seat and the sealing surface of the ball are always worn. The non-metallic elastic material is embedded in the metal seat, and the metal surface of the valve seat is well protected. This product is especially suitable for steel industry, aluminum industry, fiber, small solid particles, pulp, coal ash, petroleum gas and other media.

The valve adopts double eccentric structure, and uses the wedging effect of eccentric wheel to realize the closing and opening of sealing pair, so as to realize reliable sealing specific pressure and quick opening. Its advantages are as follows:

1. Due to the eccentric structure, the rotation radius of all points on the sealing spherical surface is different. When the sealing valve seat is closed, the closer the valve seat is, the more tight the sealing pressure is. The two-way sealing effect is excellent.

2. The valve disc adopts the full round straight through type, and has a full flow structure after opening, which has good liquidity and linear regulation performance.

3. In the process of long-term use, a new seal can be obtained by adjusting the seal ring pressing sleeve and the sealing spherical surface moving forward.

4. The operating force of the valve only acts on the minimum angle of opening or closing of the valve. When opening, the operating force decreases rapidly with the decrease of sealing specific pressure, and the sealing surface tends to be wear-free.

5. The circular flow channel has a full flow section after the valve is fully opened, and the bottom is a circular streamline structure. The deposited debris will be taken away with the flow of medium. During the closing process, the dirt deposited on the sealing surface can be removed by itself

Scale without affecting the seal.

6. The valve shaft adopts the upper and lower half shaft design, and is equipped with self-lubricating shaft sleeve. During the opening process of the valve, the friction resistance is small and the opening and closing is flexible. The unique "0" ring and the floating shaft seal replace the original butterfly valve

The packing is easy to open in the sealing process

Design: gb12237-89

Flange connection: GB / t17241.6-1998, GB / t9115 (steel)

Structural length: gb12221-89

| Valve body and cover |

GB |

WCB |

ZG08Cr18Ni9 |

ZG08Cr18Ni12Mo2 |

ZG18Cr1Mo1V |

||||||

|

ASTM |

WCB |

CF8 |

CF8M |

WC9 |

|||||||

| sphere |

GB |

WCB |

nitridation

polishing |

08Cr18Ni9 |

DB12

polishing |

08CR18Ni12Mo2 |

DB12

polishing |

08Cr18Ni9 |

D812

polishing |

||

|

ASTM |

WCB |

304 |

316 |

304 |

|||||||

| Stem |

GB |

2Cr13 |

08Cr18Ni9 |

08Cr18Ni12Mo2 |

25CrMo1V |

||||||

|

ASTM |

1420 |

304 |

316 |

F22a |

|||||||

| valve seat |

GB |

2Cc13 |

D507Mo

PTFE、PPL |

08Cr18Ni9 |

D802

PTFE、PP |

08Cr18Ni12Mo2 |

D802

PTFE、PPL |

25CrMo1V |

D802

PTFE、PPL |

||

|

ASTM |

420 |

304 |

316 |

F22a |

|||||||

| filler |

GB |

Flexible graphite | |||||||||

|

ASTM |

Flexible graphite | ||||||||||

| Bolt |

GB |

35CrMoA |

08Cr18Ni9 |

08Cr18Ni12Mo2 |

25Cr2Mo1V |

||||||

|

ASTM |

A193 B7 |

A320-B8 |

A193-B8M |

F22a |

|||||||

| Nut |

GB |

45 |

08Cr18Ni9 |

08Cr18Ni12Mo2 |

20CrMo |

||||||

|

ASTM |

A194 2H |

A194-8 |

A194-8M |

A194-4 |

|||||||

| Pressure rating |

Nominal pressurePN(MPa) |

||||||||

|

0.25 |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

6.4 |

10.0 |

||

| Shell test pressure |

0.38 |

0.9 |

1.5 |

2.4 |

3.8 |

6.0 |

9.6 |

15.0 |

|

| Sealing test pressure | High pressure liquid sealing test |

0.28 |

0.66 |

1.1 |

1.8 |

2.8 |

4.4 |

7.04 |

11.0 |

| Low pressure gas seal test |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

| Applicable conditions | Applicable media |

See "application scope of various industries"” |

|||||||

| Applicable temperature |

≤425℃ |

||||||||

| Applicable conditions | Manual (3), electric (9), pneumatic (6), etc | ||||||||

| Nominal diameter |

DN40~1000mm |

||||||||

| Applicable codes | Design and manufacture |

GB12237-89

|

|||||||

| Structural length |

GB12221-89 |

||||||||

| Flange size |

GB9113-2000、Can also be according to user requirementsAPI 6D-94 |

||||||||

| Inspection and test |

JB/T9092-99、GB/T13927-92 |

||||||||

| Nominal pressurePN | Nominal diameterDN | size(mm)Dimensions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

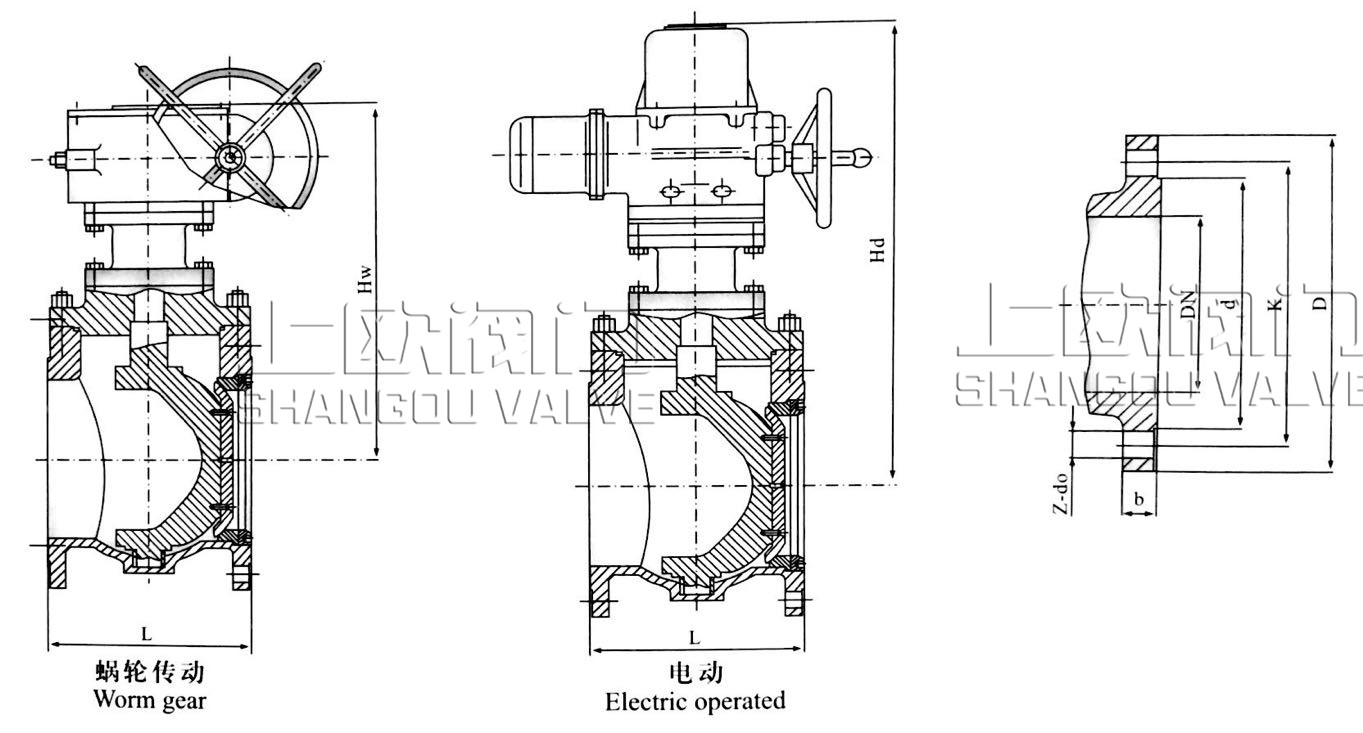

| L | D | K | d | Y | b | Z-Φdo | Ws | Hs | Hw | Hd | ||

| 1.6MPa | 50 | 124 | 165 | 125 | 100 | - | 16 | 4-Φ18 | 230 | 164 | 260 | 310 |

| 65 | 145 | 185 | 145 | 120 | - | 18 | 4-Φ18 | 250 | 180 | 275 | 330 | |

| 80 | 165 | 200 | 160 | 135 | - | 20 | 8-Φ18 | 300 | 200 | 300 | 360 | |

| 100 | 194 | 220 | 180 | 155 | - | 20 | 8-Φ18 | 320 | 235 | 335 | 390 | |

| 125 | 210 | 250 | 210 | 185 | - | 22 | 8-Φ18 | 400 | 260 | 335 | 405 | |

| 150 | 229 | 285 | 240 | 210 | - | 24 | 8-Φ23 | 500 | 280 | 375 | 440 | |

| 200 | 243 | 340 | 295 | 265 | - | 26 | 12-Φ23 | 800 | 320 | 410 | 470 | |

| 250 | 297 | 405 | 355 | 320 | - | 30 | 12-Φ25 | 100 | 355 | 485 | 550 | |

| 300 | 338 | 460 | 410 | 375 | - | 30 | 12-Φ25 | 1200 | 400 | 530 | 595 | |

| 350 | 400 | 520 | 470 | 435 | - | 34 | 16-Φ25 | - | - | 580 | 650 | |

| 400 | 400 | 580 | 525 | 485 | - | 36 | 16-Φ30 | - | - | 650 | 730 | |

| 450 | 502 | 640 | 585 | 545 | - | 40 | 20-Φ30 | - | - | 710 | 790 | |

| 500 | 533 | 715 | 650 | 608 | - | 44 | 20-Φ34 | - | - | 760 | 840 | |

| 600 | 686 | 840 | 770 | 718 | - | 48 | 20-Φ41 | - | - | 870 | 960 | |

| 700 | 762 | 910 | 840 | 788 | - | 50 | 24-Φ41 | - | - | 910 | 1080 | |

| 800 | 864 | 1025 | 950 | 898 | - | 52 | 24-Φ41 | - | - | 935 | 1125 | |

| 900 | 914 | 1125 | 1050 | 998 | - | 54 | 28-Φ41 | - | - | 995 | 1255 | |

| 1000 | 1255 | 1170 | 1110 | - | 56 | 28-Φ48 | - | - | 1080 | 1385 | ||

| 1200 | 1485 | 1390 | 1325 | - | 58 | 32-Φ54 | - | - | 1175 | 1490 | ||

| 1400 | 1685 | 1590 | 1525 | - | 60 | 36-Φ54 | - | - | 1280 | 1565 | ||

| 2.5MP | 50 | 124 | 165 | 125 | 100 | - | 20 | 4-Φ18 | 230 | 164 | 260 | 310 |

| 65 | 145 | 185 | 145 | 120 | - | 22 | 8-Φ18 | 250 | 180 | 275 | 330 | |

| 80 | 165 | 200 | 160 | 135 | - | 22 | 8-Φ18 | 300 | 200 | 300 | 360 | |

| 100 | 194 | 230 | 190 | 160 | - | 24 | 8-Φ23 | 320 | 235 | 335 | 390 | |

| 125 | 210 | 270 | 220 | 188 | - | 28 | 8-Φ25 | 400 | 260 | 355 | 405 | |

| 150 | 229 | 300 | 250 | 218 | - | 30 | 8-Φ25 | 500 | 280 | 375 | 440 | |

| 200 | 243 | 360 | 310 | 278 | - | 34 | 12-Φ25 | 800 | 320 | 410 | 470 | |

| 250 | 297 | 425 | 370 | 332 | - | 36 | 12-Φ30 | 1000 | 355 | 485 | 550 | |

| 300 | 338 | 485 | 430 | 390 | - | 40 | 16-Φ30 | 1200 | 400 | 530 | 595 | |

| 350 | 400 | 555 | 490 | 448 | - | 44 | 16-Φ34 | - | - | 580 | 650 | |

| 400 | 400 | 620 | 550 | 505 | - | 48 | 16-Φ34 | - | - | 650 | 730 | |

| 450 | 502 | 670 | 600 | 555 | - | 50 | 20-Φ34 | - | - | 710 | 790 | |

| 500 | 533 | 730 | 660 | 610 | - | 52 | 20-Φ41 | - | - | 760 | 840 | |

| 60td> | - | 870 | 960 | |||||||||

| 700 | 762 | 960 | 875 | 815 | - | 60 | 24-Φ48 | - | - | 990 | 1080 | |

| 800 | 864 | 1085 | 990 | 930 | - | 64 | 24-Φ48 | - | - | 935 | 1125 | |

| 900 | 914 | 1185 | 1090 | 1025 | - | 66 | 28-Φ54 | - | - | 995 | 1255 | |

| 1000 | 138-Φ54 | - | - | 995 | 1255 | |||||||

| 1000 | 1320 | 1210 | 1140 | - | 68 | 28-Φ58 | - | - | 1080 | 1385 | ||

| 1200 | 1520 | 1420 | 1350 | - | 72 | 32-Φ58 | - | - | 1175 | 1490 | ||

| 1400 | 1755 | 1640 | 1560 | - | 78 | 36-Φ65 | - | - | 1280 | 1565 | ||

Note: due to the limitation of the number of words in the webpage, many sizes cannot be listed. If you have any requirements, please contact us at any time

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website