Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > Q941FElectric explosion proof stainless steel flange ball valvePN10~PN16

Location:Home > Product Center > Ball Valve > Q941FElectric explosion proof stainless steel flange ball valvePN10~PN16

Q941FThe electric explosion-proof stainless steel flange ball valve pn10-pn16 is composed of ball valve and 3410 electric actuator. It uses 220 V AC single-phase power supply as the driving power supply and receives 4-20madc or 1-5vdc input signal from computer regulator or operator to operate. The explosion-proof grade is ExdIIBT4, and exdiict6 can also be used.

Q941FThe electric explosion-proof stainless steel flange ball valve pn10-pn16 is composed of ball valve and 3410 electric actuator. It uses 220 V AC single-phase power supply as the driving power supply and receives 4-20madc or 1-5vdc input signal from computer regulator or operator to operate. The explosion-proof grade is ExdIIBT4, and exdiict6 can also be used. The special processing technology and Zui new sealing material are used to make the surface roughness and roundness of the ball meet the standard requirements, so as to improve the sealing performance, service life and high temperature resistance. At the same time, the plate moving handle drives the valve rod to drive the ball to rotate, so that the medium can pass smoothly.

1. Design and manufacture: gb12237-89, api608, API 6D, JPI 7s-48, BS5351, din3357.

2. Flange dimensions: JB / t74-90 (jb74-90), gb9112-9131, hgj44-76, sh3406, ANSI B16.5, JIS b2212-2214, NF e29-211, din2543.

3. Structural length: gb12221-89, ANSI B16.10, JIS B2002, NF e29-305, din3202.

4. Main test: JB / T 9092, API 598.

Q941FMain parts and components materials of electric explosion proof stainless steel flange ball valve PN10 ~ PN16

| Nominal diameter mm | 15 | 20 | 25 | 32 | 40 | 50 | 80 | 100 | |

|---|---|---|---|---|---|---|---|---|---|

| Rated flow coefficientKv | 20 | 38 | 72 | 110 | 170 | 270 | 510 | 940 | |

| Nominal pressure MPa | 1.0;1.6;6.4 | ||||||||

| Rated angle ° | 0~90 | ||||||||

| Flow characteristics | Go ahead | ||||||||

| Medium temperature ℃ | -20~120 | ||||||||

| body material | HT200 ;ZG230-450 ;ZG1Cr18Ni9Ti;ZG0Cr18Ni12Mo2Ti | ||||||||

| Sphere material | 1Cr18Ni9;0Cr18Ni12Mo2Ti | ||||||||

| With actuator model | PN10、16 | 361RSA-05 341RSA-05 |

361RS(X)B-10 341RS(X)B-10 |

361RSC-30 341RSC-30 |

|||||

| PN64 | 361RS(X)B-10 341RS(X)B-10 |

361RSC-30 341RSC-30 |

361RSD-150 341RSD-150 |

||||||

| model | zuiLarge output torque | Action time 60/50HZ | Zui large shaft diameter | Motor class F | Rated current(A)50HZ | Handwheel speed | weight | |||

|---|---|---|---|---|---|---|---|---|---|---|

| single-phase | three-phase | |||||||||

| N·m | 90° | mm | W | 110V | 220V | 380V | 440V | N | kg | |

| YXQ-008 | 80 | 13/16 | φ20 | 15 | 1.20 | 0.45 | N/A | N/A | 10 | 7.4 |

| YXQ-015 | 150 | 21/25 | φ22 | 40 | 1.65 | 0.88 | 0.31 | 0.30 | 11 | 13 |

| YXQ-020 | 200 | 21/25 | φ22 | 40 | 1.67 | 0.89 | 0.31 | 0.30 | 11 | 13 |

| YXQ-030 | 300 | 26/31 | φ35 | 40 | 1.85 | 0.92 | 0.35 | 0.34 | 13.5 | 23 |

| YXQ-050 | 500 | 26/31 | φ35 | 90 | 3.60 | 1.55 | 0.59 | 0.58 | 13.5 | 24 |

| YXQ-060 | 600 | 26/31 | φ35 | 90 | 3.65 | 1.60 | 0.60 | 0.59 | 13.5 | 24 |

| YXQ-080 | 800 | 31/37 | φ45 | 180 | 4.10 | 2.15 | 0.85 | 0.79 | 16.5 | 29 |

| YXQ-120 | 1200 | 31/37 | φ45 | 180 | 4.20 | 2.35 | 0.87 | 0.81 | 16.5 | 29 |

| YXQ-200 | 2000 | 93/112 | φ65 | 180 | 4.10 | 2.15 | 0.85 | 0.79 | 49.5 | 78 |

| YXQ-300 | 3000 | 93/112 | φ65 | 180 | 4.20 | 2.35 | 0.87 | 0.81 | 49.5 | 78 |

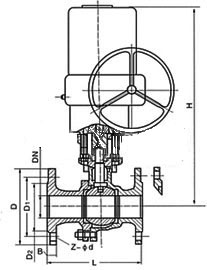

| Nominal diameter | L | D | D1 | H1 | h3 | H3 | D2 |

|---|---|---|---|---|---|---|---|

| 15 | 112 | 95 | 65 | 48.5 | 120 | 322 | 260 |

| 20 | 120 | 105 | 75 | 51.5 | 120 | 325 | 260 |

| 25 | 128 | 115 | 85 | 55 | 120 | 333 | 260 |

| 32 | 150 | 135 | 100 | 67.5 | 155 | 427 | 290 |

| 40 | 170 | 145 | 110 | 72.5 | 155 | 448 | 290 |

| 50 | 180 | 160 | 125 | 72.5 | 155 | 456 | 290 |

| 80 | 200 | 195 | 160 | 100 | 165 | 535 | 380 |

| 100 | 230 | 215 | 180 | 110 | 165 | 568 | 380 |

| 125 | 356 | 245 | 210 | 152 | 165 | 635 | 380 |

| 150 | 394 | 280 | 240 | 170 | 165 | 700 | 380 |

| 200 | 457 | 335 | 295 | 300 | 120 | 860 | 520 |

1. Be careful in installation and construction, and do not hit the valve.

2. Before installation, the ball valve should be inspected to check the specification and model, and identify whether there is damage, especially for the valve stem. Turn it a few times to see if it is skewed, because Zui is prone to bump the stem during transportation. Also remove the debris in the valve.

3. When lifting the ball valve, the rope should not be tied to the hand wheel or the valve stem to avoid damage to these parts, but should be tied to the valve body.

4. The pipeline connected to the ball valve must be cleaned. Compressed air can be used to blow away iron oxide chips, mud and sand, welding slag and other impurities. These debris, not only easy to scratch the sealing surface of the ball valve, in which large particles of debris (such as welding slag), but also block the small valve, so that its failure.

5. The position of valve handle rotation should be reserved during installation. 6. The ball valve cannot be used as throttling. 7. The ball valve with transmission mechanism shall be installed vertically.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website