Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > Q941f electric three way flange ball valve PN16 ~ PN40

Location:Home > Product Center > Ball Valve > Q941f electric three way flange ball valve PN16 ~ PN40

The four seat sealing three-way ball valve has beautiful appearance and compact and reasonable structure. It can not only realize the switching of medium flow direction, but also connect the three channels. At present, it can also close any channel to connect the other two channels, so as to flexibly control the convergence or diversion of medium in the pipeline.

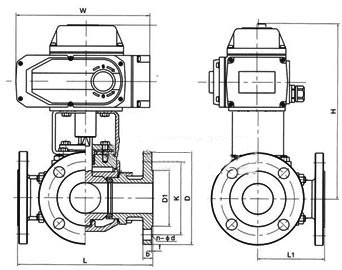

Q941f electric three-way flange ball valve pn16-pn40 is composed of yxr / Q series intelligent actuator and three-way ball valve. It is a kind of rotary cut-off regulating valve with the advantages of tight closing, compact structure, light weight and convenient maintenance. It is widely used in pipeline automation control of gas, liquid, steam, oil and other corrosive media.

The valve seat is compact and has good sealing performance. It can switch the flow direction of medium in the pipeline. It can also make two mutually perpendicular channels connected or closed.

The four seat sealing three-way ball valve has beautiful appearance and compact and reasonable structure. It can not only realize the switching of medium flow direction, but also connect the three channels. At present, it can also close any channel to connect the other two channels, so as to flexibly control the convergence or diversion of medium in the pipeline.

The three-way ball valve is divided into L-type and T-type, and the medium flow direction is shown in the figure below. L-type three-way ball valve is suitable for medium flow direction switching, which can connect two mutually perpendicular channels. T-type three-way ball valve is suitable for medium diversion, confluence or flow direction switching. T-type hole can make three channels connected with each other or two of them. Three way ball valve generally adopts two seat structure, or four seat structure according to user requirements.

Electric actuator type: PSQ, 3810R, DTR angle travel actuator can be selected. The explosion-proof type is 3810 series.

Technical parameters and performance: please refer to the instructions of corresponding actuator and valve positioner.

Control accuracy: 0.1% ~ 3.1% adjustable.

Receive control signal: 0 ~ 10 mA.DC 、 4~20 mA.DC Or 1-5v.dcv key selection: 1. When the input signal is interrupted: "interrupt" mode (on, off, off) 2. Forward and reverse action selection; 3. Control precision selection.

Electric device full open, full closed position automatic positioning calibration, convenient and accurate.

According to the input signal and the position of the electric device, the intelligent step adjustment and automatic positioning are carried out, and the oscillation suppression precision is high.

Output electric device position signal: 4 ~ 20 mA.DC The corresponding electric device is fully closed and fully open.

| Nominal pressure PN |

Room temperature working pressure |

housing Test pressure |

Airtight seal Test pressure |

High pressure seal Test pressure |

|---|---|---|---|---|

| 1.6 | 1.6 | 2.4 | 0.6 | 1.76 |

| 2.5 | 2.5 | 3.8 | 0.6 | 2.75 |

| 4.0 | 4.0 | 6.0 | 0.6 | 4.4 |

| C1aSSl50 | 2.0 | 3.0 | 0.6 | 2.2 |

| Body cover | GB | WCB | ZGlCrl8Ni9Ti | ZGOCfl8Nil2M02Ti | |||

|---|---|---|---|---|---|---|---|

| ASTM | WCB | CF8 | CF8M | ||||

| sphere | GB | 2Cfl3 | 1Cfl8Ni9Ti | 0Cfl8Ni12M02Ti | |||

| ASTM | 420 | 304 | 316 | ||||

| Stem | GB | 2Crl3 | 1Crl8Ni9Ti | 0Crl8Ni12M02Ti | |||

| ASTM | 420 | 304 | 316 | ||||

| Seat sealing surface | GB | teflon | Para polyphenylene | teflon | Para polyphenylene | teflon | Para polyphenylene |

| ASTM | teflon | Para polyphenylene | teflon | Para polyphenylene | teflon | Para polyphenylene | |

| filler | GB | teflon | Flexible graphite | teflon | Flexible graphite | teflon | Flexible graphite |

| ASTM | teflon | Flexible graphite | teflon | Flexible graphite | teflon | Flexible graphite | |

| Bolt | GB | 35 | 0Crl8Ni9 | 0Crl8Ni9 | |||

| ASTM | A193B7 | A320-B8 | A320-B8 | ||||

| Nut | GB | 45 | 0Cfl8Ni9 | 0Crl8Ni9 | |||

| ASTM | A1942H | A194-8 | A194-8 | ||||

| Nominal pressure Or pressure level |

Nominal diameter | size(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | in | L | L1 | D | D1 | D2 | b | z-Φd | |

| PN1.6MPa | 15 | 130 | 65 | 95 | 65 | 45 | 14 | 4-14 | |

| 20 | 150 | 75 | 105 | 75 | 55/58 | 14/16 | 4-14 | ||

| 25 | 160 | 80 | 115 | 85 | 65/68 | 14/16 | 4-14 | ||

| 32 | 180 | 90 | 135/140 | 100 | 78 | 16 | 4-18 | ||

| 40 | 200 | 100 | 145/150 | 110 | 85/88 | 16 | 4-18 | ||

| 50 | 230 | 115 | 160/165 | 125 | 100/102 | 16/18 | 4-18 | ||

| 65 | 290 | 145 | 180/185 | 145 | 120/122 | 18 | 4-18 | ||

| 80 | 310 | 155 | 195/200 | 160 | 135/138 | 20 | 4-18 | ||

| 100 | 350 | 175 | 215/220 | 180 | 155/158 | 20 | 4-18 | ||

| 125 | 400 | 200 | 245/250 | 210 | 185/188 | 22 | 4-18 | ||

| 150 | 480 | 240 | 280/285 | 240 | 210/212 | 24/22 | 8-23/8-22 | ||

| PN2.5MPa | 15 | 130 | 65 | 95 | 65 | 45 | 16 | 4-14 | |

| 20 | 150 | 75 | 105 | 75 | 55/58 | 16 | 4-14 | ||

| 25 | 160 | 80 | 115 | 85 | 65/68 | 16 | 4-14 | ||

| 32 | 180 | 90 | 135/140 | 100 | 78 | 18 | 4-18 | ||

| 40 | 200 | 100 | 145/150 | 110 | 85/88 | 18 | 4-18 | ||

| 50 | 230 | 115 | 160/165 | 125 | 100/102 | 20 | 4-18 | ||

| 65 | 290 | 145 | 180/185 | 145 | 120/122 | 22 | 8-18 | ||

| 80 | 310 | 155 | 195/200 | 160 | 135/138 | 22/24 | 8-18 | ||

| 100 | 350 | 175 | 230/235 | 190 | 160/162 | 24 | 8-23/8-22 | ||

| 125 | 400 | 200 | 270 | 220 | 188 | 28/26 | 8-25/8-26 | ||

| 150 | 480 | 240 | 300 | 250 | 218 | 30/28 | 8-25/8-26 | ||

| PN4.0MPa | 15 | 130 | 65 | 95 | 65 | 45 | 16 | 4-14 | |

| 20 | 150 | 75 | 105 | 75 | 55/58 | 16 | 4-14 | ||

| 25 | 160 | 80 | 115 | 85 | 65/68 | 16 | 4-14 | ||

| 32 | 180 | 90 | 135/140 | 100 | 78 | 18 | 4-18 | ||

| 40 | 200 | 100 | 145/150 | 110 | 85/88 | 18 | 4-18 | ||

| 50 | 230 | 115 | 160/165 | 125 | 100/102 | 20 | 4-18 | ||

| 65 | 290 | 145 | 180/185 | 145 | 120/122 | 22 | 8-18 | ||

| 80 | 310 | 155 | 195/200 | 160 | 135/138 | 22 | 8-18 | ||

| 100 | 350 | 175 | 230/235 | 190 | 160/162 | 24 | 8-23/8-22 | ||

| 125 | 400 | 200 | 270 | 220 | 188 | 28 | 8-25/8-26 | ||

| 150 | 480 | 240 | 300 | 250 | 218 | 30 | 8-25/8-26 | ||

Note: 1. If expressed by fraction, the numerator is JB / t74-90 Series 2 size (equivalent to the size of the original machine standard jb74-90-59), and the denominator is JB / t74-90 Series 1, gb9112-9131 (pn1.6, 2.5, 4.0Mpa) and hgj44-76. 2. In the table, the numerator is ANSI B16.5, and the denominator is gb9112-9131 and sh3406.

1. Be careful in installation and construction, and do not hit the valve.

2. Before installation, the ball valve should be inspected to check the specification and model, and identify whether there is damage, especially for the valve stem. Turn it a few times to see if it is skewed, because Zui is prone to bump the stem during transportation. Also remove the debris in the valve.

3. When lifting the ball valve, the rope should not be tied to the hand wheel or the valve stem to avoid damage to these parts, but should be tied to the valve body.

4. The pipeline connected to the ball valve must be cleaned. Compressed air can be used to blow away iron oxide chips, mud and sand, welding slag and other impurities. These debris, not only easy to scratch the sealing surface of the ball valve, in which large particles of debris (such as welding slag), but also block the small valve, so that its failure.

5. The position of valve handle rotation should be reserved during installation. 6. The ball valve cannot be used as throttling. 7. The ball valve with transmission mechanism shall be installed vertically.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website