Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > Q941Y Soft seal electric floating ball valve PN16~PN63

Location:Home > Product Center > Ball Valve > Q941Y Soft seal electric floating ball valve PN16~PN63

The operation mode of q941y soft seal electric floating ball valve pn16-pn63 is electric, the connection is flange connection, the floating ball straight through type, the valve seat sealing surface material is hard alloy (q941y), the nominal pressure is pn16-pn63, the nominal size is DN 15-dn300, the applicable temperature is - 29-450 ℃, and the valve body materials are carbon steel, stainless steel and alloy steel, Q941y soft seal electric floating ball valve is suitable for two position cut-off and adjustment.

The operation mode of q941y soft seal electric floating ball valve pn16-pn63 is electric, the connection is flange connection, the floating ball straight through type, the valve seat sealing surface material is hard alloy (q941y), the nominal pressure is pn16-pn63, the nominal size is DN 15-dn300, the applicable temperature is - 29-450 ℃, and the valve body materials are carbon steel, stainless steel and alloy steel, Q941y soft seal electric floating ball valve is suitable for two position cut-off and adjustment. The valve is directly connected with the actuator, which is composed of UNIC, PSQ, HQ, DHL and other electric actuators (or other types of electronic electric actuators can be configured according to user requirements) and ultra short ball valve. The electric actuator has a built-in servo system, which can be controlled by inputting 4-20mA signal and 220V AC power supply without additional servo amplifier. Compared with ordinary electric ball valve, it has the advantages of compact structure, small volume, light weight, close distance between valve seat and end face flange, less material retention and superior sealing performance.

Performance parameters of q941y soft seal electric floating ball valve PN16 ~ pn63

| model | PN | working pressure / MPa | Applicable temperature / ℃ | Applicable media |

| Q941F-16C | 16 | 1.6 | ≤ 180 | Water, gas and oil |

| Q941F-25C | 25 | 2.5 | ||

| Q941F-40C | 40 | 4 | ||

| Q941Y-16C | 16 | 1.6 | ≤ 425 | Granular media in water, gas and oil |

| Q941Y-25C | 25 | 2.5 | ||

| Q941Y-40C | 40 | 4 | ||

| Q941F-16P | 16 | 1.6 | ≤ 180 | Nitric acid |

| Q941F-25P | 25 | 2.5 | ||

| Q941F-40P | 40 | 4 | ||

| Q941Y-16P | 16 | 1.6 | ≤ 450 | Granular media in water, gas and oil |

| Q941Y-25P | 25 | 2.5 | ||

| Q941Y-40P | 40 | 4 | ||

| Q941F-16R | 16 | 1.6 | ≤ 180 | Nitric acid |

| Q941F-25R | 25 | 2.5 | ||

| Q941F-40R | 40 | 4 | ||

| Q941Y-16R | 16 | 1.6 | ≤ 450 | Granular media in water, gas and oil |

| Q941Y-25R | 25 | 2.5 | ||

| Q941Y-40R | 40 | 4 | ||

| Q941F-16I | 16 | 1.6 | -29~150 | Water, steam, gas, oil, etc |

| Q941F-25I | 25 | 2.5 | ||

| Q941F-40I | 40 | 4 | ||

| Q941F-63I | 63 | 6.3 |

| model | Material Science | |||

| valve body | Stem | Sealing surface | filler | |

| Q941F-16C | WCB | 2Cr13 | PTFE、enhance PTFE | PTFE |

| Q941F-25C | 304 | |||

| Q941F-40C | 316 | |||

| Q941Y-16C | 1Cr18Ni9Ti | Cobalt base metal surfacing | Flexible graphite | |

| Q941Y-25C | 1Cr18Ni12Mo2Ti | |||

| Q941Y-40C | ||||

| Q941F-16P | CF8 | 304 | PTFE、enhance PTFE | PTFE |

| Q941F-25P | ||||

| Q941F-40P | ||||

| Q941Y-16P | Cobalt base metal surfacing | Flexible graphite | ||

| Q941Y-25P | ||||

| Q941Y-40P | ||||

| Q941F-16R | CF8M | 316 | PTFE、enhance PTFE | PTFE |

| Q941F-25R | ||||

| Q941F-40R | ||||

| Q941Y-16R | Cobalt base metal surfacing | Flexible graphite | ||

| Q941Y-25R | ||||

| Q941Y-40R | ||||

| Q941F-16I | Alloy steel | stainless steel | — | — |

| Q941F-25I | ||||

| Q941F-40I | ||||

| Q941F-63I | ||||

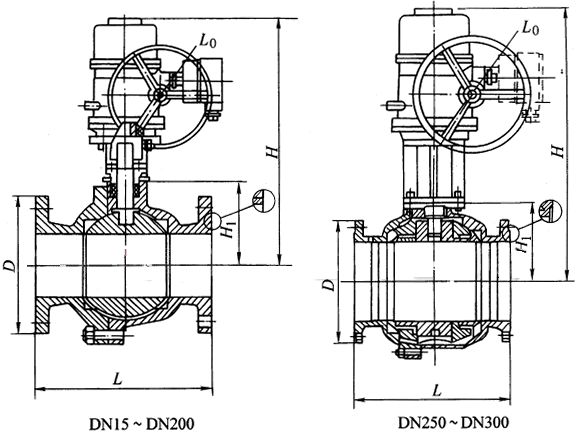

| DN | L | D | H | H1 | L0 | weight / kg |

| 15 | 130 | 95 | 340 | 39 | 120 | 25 |

| 20 | 130 | 105 | 353 | 43 | 120 | 26 |

| 25 | 140 | 115 | 353 | 48 | 120 | 27 |

| 32 | 165 | 135 | 378 | 58 | 120 | 28 |

| 40 | 165 | 145 | 378 | 62.5 | 120 | 30 |

| 50 | 200 | 160 | 405 | 76 | 418 | 37 |

| 65 | 220 | 180 | 435 | 86 | 418 | 42 |

| 80 | 250 | 195 | 450 | 100 | 418 | 51 |

| 100 | 280 | 215 | 570 | 131 | 418 | 90 |

| 125 | 320 | 245 | 592 | 148 | 418 | 125 |

| 150 | 360 | 280 | 623 | 173 | 585 | 178 |

| 200 | 457 | 335 | 689 | 219 | 585 | 243 |

| 250 | 533 | 405 | 765 | 260 | 585 | 380 |

| 300 | 610 | 460 | 885 | 305 | 585 | 535 |

| DN | L | D | H | H1 | L0 | weight / kg |

| 15 | 140 | 95 | 340 | 39 | 120 | 25 |

| 20 | 152 | 105 | 353 | 43 | 120 | 26 |

| 25 | 165 | 115 | 353 | 48 | 120 | 28 |

| 32 | 178 | 135 | 378 | 58 | 120 | 30 |

| 40 | 190 | 145 | 378 | 62.5 | 120 | 32 |

| 50 | 216 | 160 | 405 | 76 | 418 | 41 |

| 65 | 241 | 180 | 435 | 86 | 418 | 50 |

| 80 | 283 | 195 | 450 | 100 | 418 | 57 |

| 100 | 305 | 230 | 578 | 134 | 418 | 103 |

| 125 | 381 | 270 | 597 | 148 | 418 | 145 |

| 150 | 403 | 300 | 643 | 173 | 585 | 213 |

| 200 | 419 | 360 | 728 | 223 | 585 | 285 |

| 250 | 568 | 425 | 765 | 283 | 585 | 415 |

| 300 | 648 | 485 | 885 | 321 | 585 | 770 |

| DN | L | D | H | H1 | L0 | weight/ kg |

| 15 | 140 | 95 | 340 | 39 | 120 | 26 |

| 20 | 152 | 105 | 353 | 43 | 120 | 27 |

| 25 | 165 | 115 | 353 | 48 | 120 | 30 |

| 32 | 178 | 135 | 378 | 58 | 120 | 31 |

| 40 | 190 | 145 | 378 | 62.5 | 120 | 33 |

| 50 | 216 | 160 | 405 | 76 | 418 | 41 |

| 65 | 241 | 180 | 435 | 86 | 418 | 50 |

| 80 | 283 | 195 | 450 | 100 | 418 | 57 |

| 100 | 305 | 230 | 578 | 134 | 418 | 108 |

| 125 | 381 | 270 | 597 | 148 | 418 | 182 |

| 150 | 403 | 300 | 643 | 173 | 585 | 220 |

| 200 | 419 | 375 | 728 | 223 | 585 | 303 |

| 250 | 568 | 445 | 863 | 283 | 585 | 455 |

| 300 | 648 | 510 | 901 | 321 | 585 | 740 |

| DN | L | D | H | H1 | weight / kg |

| 15 | 140 | 105 | 70 | 210 | |

| 20 | 152 | 130 | 75 | 250 | 7.2 |

| 25 | 165 | 140 | 85 | 261 | 9 |

| 32 | 178 | 155 | 100 | 262 | 13 |

| 40 | 190 | 170 | 115 | 294 | 15 |

| 50 | 216 | 180 | 130 | 352 | 19 |

| 65 | 241 | 205 | 155 | 398 | 42 |

| 80 | 283 | 215 | 180 | 461 | 50 |

| 100 | 305 | 250 | 210 | 488 | 68 |

| 125 | 381 | — | — | — | 108 |

| 150 | 403 | — | — | — | 140 |

1. Be careful in installation and construction, and do not hit the valve.

2. Before installation, the ball valve should be inspected to check the specification and model, and identify whether there is damage, especially for the valve stem. Turn it a few times to see if it is skewed, because Zui is prone to bump the stem during transportation. Also remove the debris in the valve.

3. When lifting the ball valve, the rope should not be tied to the hand wheel or the valve stem to avoid damage to these parts, but should be tied to the valve body.

4. The pipeline connected to the ball valve must be cleaned. Compressed air can be used to blow away iron oxide chips, mud and sand, welding slag and other impurities. These debris, not only easy to scratch the sealing surface of the ball valve, in which large particles of debris (such as welding slag), but also block the small valve, so that its failure.

5. The position of valve handle rotation should be reserved during installation. 6. The ball valve cannot be used as throttling. 7. The ball valve with transmission mechanism shall be installed vertically.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website