Telephone:

0577-67975099

Location:Home > Product Center > Ball Valve > GWXDFDouble direction hard seal ball valve

Location:Home > Product Center > Ball Valve > GWXDFDouble direction hard seal ball valve

Most of the valves in the pipe network system are mainly used to cut off and regulate the medium. These valves account for a large proportion in the whole system and have a large amount of consumption. They are required to be durable and cost-effective. They should be able to adjust and cut off the medium when the medium is in forward flow, and prevent the medium from flowing backward when the pressure difference changes or repair, that is, it has the function of two-way cut-off

Most of the valves in the world's most exquisite and cost-effective ball valve network system are mainly used to cut off and regulate the medium. These valves account for a large proportion of the whole system and have a large amount of consumption. They are required to be durable and cost-effective. They should be able to adjust and cut off the medium when the medium is in forward flow, and can prevent the medium backflow during the pressure difference transformation or maintenance, that is, it has two-way Cut off function. At present, the main application of these valves in the pipe network system are stop valve, gate valve, butterfly valve and ball valve. The globe valve and gate valve have good two-way cut-off function, good sealing performance and service life. They are both the first of the valve. However, due to the congenital restriction of the cut-off structure, the globe valve has large shape and large operating torque, so it is unable to produce large diameter. At present, the largest one in the market is only dn400; The gate valve has no regulating function, so there is a great danger that the gate will fall off when it is used to regulate the flow. However, the large diameter gate valve has many difficulties in manufacturing and transportation because of its huge shape and height. Compared with gate valve, butterfly valve has the characteristics of short opening and closing time, small operating torque, small installation space and light weight. In some working conditions, butterfly valve is used instead of gate valve. But for a long time, the sealing performance of butterfly valve has not fully met the market requirements. In addition to the middle line rubber lined butterfly valve can be sealed in a certain pressure range, other structures are basically unidirectional flow. The middle line structure can not be popularized due to the limitation of rubber. After improvement, the bi-directional butterfly valve with stainless steel elastic plate structure appears in the market, but its price is high, its service life is limited, and it has not been popularized. Ball valve with small flow resistance, long life and many other advantages, has been recognized by the market, but its price is high. At present, it is mainly used in oil, natural gas, gas and other media more important pipeline, in general pipe network, especially in water system.

Is there any valve with superior performance, moderate price, adjustable, bi-directional sealing, and not limited by caliber and space size?

The answer is yes! The bi-directional hard seal ball valve developed by Shanghai European Valve Co., Ltd. can fully meet the above requirements. The valve combines the superior sealing performance of ball valve and the superior structural performance of butterfly valve, which makes it not only has the performance advantages of bi-directional sealing, adjustable and long service life of ball valve, but also has the structural advantages of small volume and light weight of butterfly valve. In fact, it is an eccentric hemisphere valve with butterfly structure! Led by the post doctoral cooperation research and development center of our company and supported by the Postdoctoral Station of Hunan University, the modern design methods and technologies were adopted for the valve, including static simulation analysis, dynamic simulation analysis, multidisciplinary design optimization and performance analysis, etc., which highlighted the solution to the problems of energy consumption, consumables, pressure loss and sealing performance of the existing valve, and developed a new generation with low energy consumption, low energy consumption, high pressure loss and sealing performance This paper introduces a new design method and technology for large diameter ball valve with two-way hard seal. The book is published by China Water Conservancy and Hydropower Publishing House (available in major bookstores nationwide). Compared with the traditional globe valve and gate valve with two-way sealing function, the valve breaks through the limitation of diameter and space size, and has absolute cost-effective advantage compared with ball valve in water system pipe network. It can be widely used in metallurgy, mining, petrochemical, chemical, electric power, environmental protection, municipal and other industries and departments of the pipe network system, as the opening and closing, regulating use.

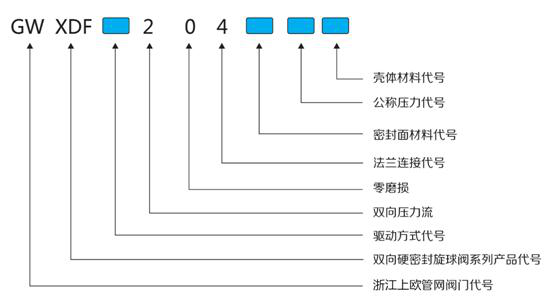

Driving mode:

| Code name |

3 |

6 |

7 |

9 |

| Driving mode | Worm gear | Pneumatic | Hydrodynamics | Electric |

Sealing surface material:

| Code name |

H |

R |

Y |

| Sealing surface material | Martensite does not induce steel | austenitic stainless steel | Cemented carbide |

Nominal pressure:

| Code name |

6 |

10 |

16 |

25 |

40 |

63 |

|

Nominal pressure(Mpa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

6.3 |

Shell material:

| Code name |

C |

P |

R |

| Material Science |

WCB |

lCrl8Ni9Ti |

lCrl8Nil2MoTi、 |

Two way hard seal ball valve is widely used in pump outlet, pipe network system, especially municipal, fire control and other network, annular pipe network. In this kind of two-way flow condition, one valve is equivalent to two ordinary one-way sealing valves, with high cost performance. It can be used to open, close and adjust the medium of pipe network system in metallurgy, petrochemical, electric power, chemical industry, environmental protection, municipal and other industries and departments.

The latest version of undated reference documents is applicable to this product.

| Standard content | Standard number | Standard name |

| Enterprise standard |

Q/OPJF006-2012 |

GWXDFDouble direction flow hard impact hard seal ball valve |

| Design and manufacture standard |

CJ/T283-2008 |

Eccentric hemisphere valve of Urban Construction Department |

|

GB/T12237 |

Design and manufacture standard | |

|

GB/T12238 |

General purpose valves - Flanged and wafer butterfly valves | |

| Structural length standard |

GB/T12221 |

Metal valve structure length |

| Flange standard |

GB/T9113.1-4 |

Integral steel pipe flange / customer specified standard |

|

GB/T17241.6 |

Integral cast iron pipe flange | |

| Inspection and test standards |

GB/T13927 |

Pressure test for general purpose valves |

|

JB/T9092 |

Test and inspection of valves | |

| Standard of materials used |

GB/T12227 |

Technical conditions of ductile iron castings for general purpose valves |

|

GB/T12229 |

Technical specification of carbon steel castings for general purpose valves | |

| Technical requirements of austenitic steel castings for general purpose valves |

|

Nominal diameter(mm) |

Nominal pressure(MPa) |

Test pressure(MPa) |

Test pressure(C) |

Applicable media | ||

| Shell strength test | Forward sealing test | Reverse sealing test | ||||

|

DN50~3000 mm |

0.6 |

0.9 |

0.66 |

0.66 |

0-80 is not indicated. (: below, can produce below 0-200 ℃ | Water, sewage, oil, etc |

|

1.0 |

1.5 |

1.1 |

1.1 |

|||

|

1.6 |

2.4 |

1.76 |

1.76 |

|||

|

2.5 |

3.75 |

2.75 |

2.75 |

|||

|

4.0 |

6.0 |

4.4 |

4.4 |

|||

|

6.3 |

9.45 |

6.93 |

6.93 |

|||

| Part name | Material Science | |

|

|

name | Brand |

| Brand | cast steel |

WCB |

|

|

austenitic stainless steel |

304、 316 |

| Valve plate | cast steel |

WCB |

|

|

austenitic stainless steel |

304、 316 |

| Stem | Martensitic stainless steel |

1013、2Crl3 |

| valve seat | austenitic stainless steel |

304、 316 |

|

|

Nitriding of Ni Cr nodular iron |

QT400Ni2Cr |

| Bearing | Aluminum bronze, tin bronze |

ZCuAl1OFe3, ZCuSn5-5-5 |

| Sealing element | rubber |

NBR、EPDM |

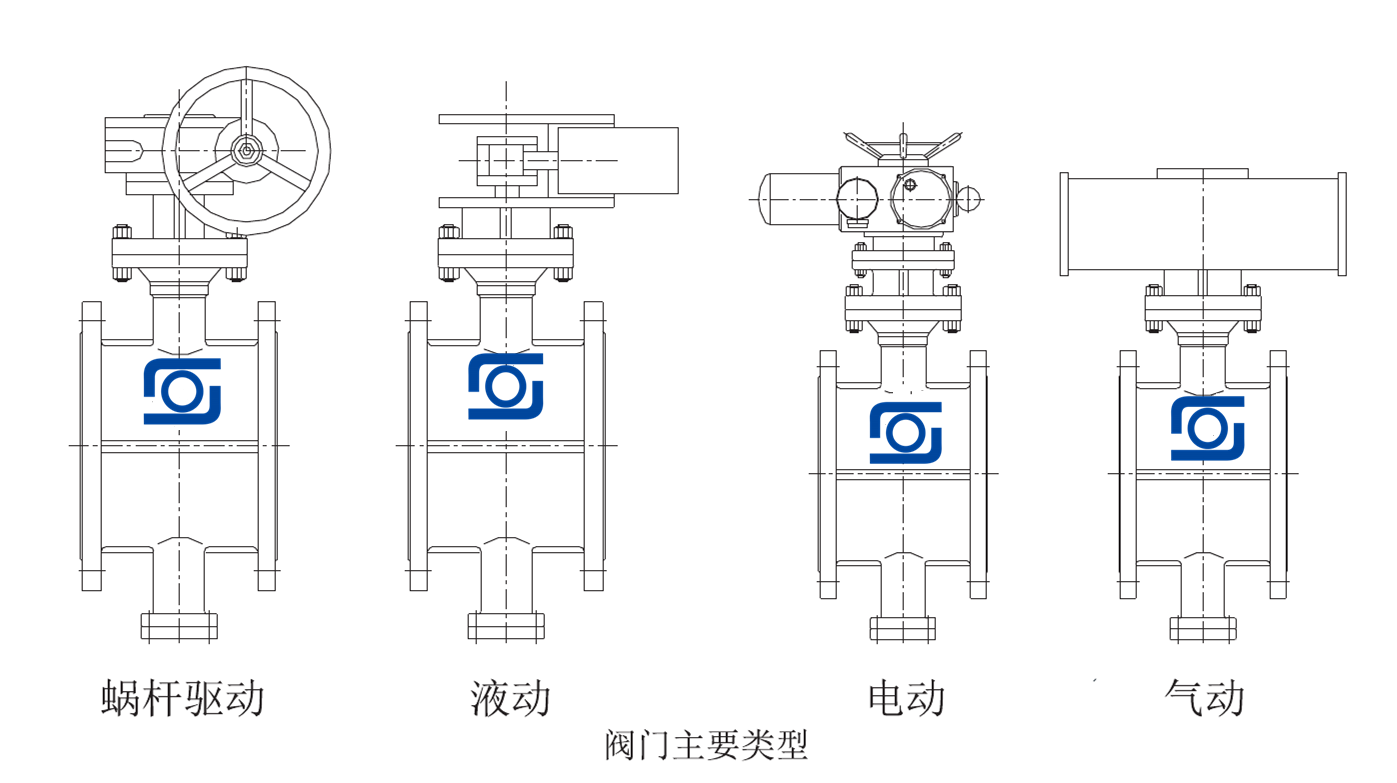

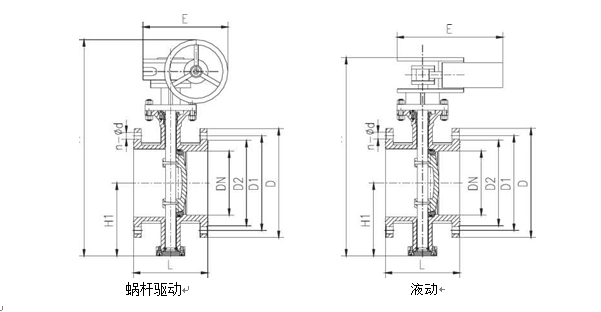

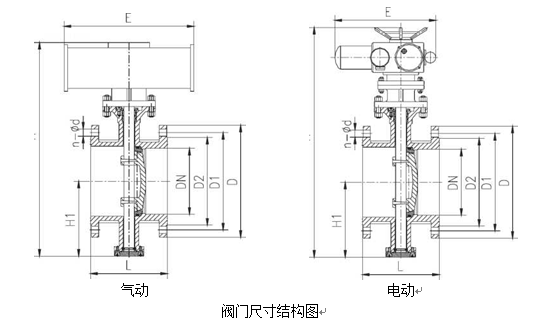

1. Main types: the main types of the valve are worm gear, electric, pneumatic and hydraulic, among which pneumatic valve and hydraulic valve are suitable for occasions with pressure gas source and pressure liquid source.

| Driving mode | worm drive | Hydrodynamics | Electric | Pneumatic |

| Flange model |

GWXDF3204 |

GWXDF7204 |

GWXDF9204 |

GWXDF6204 |

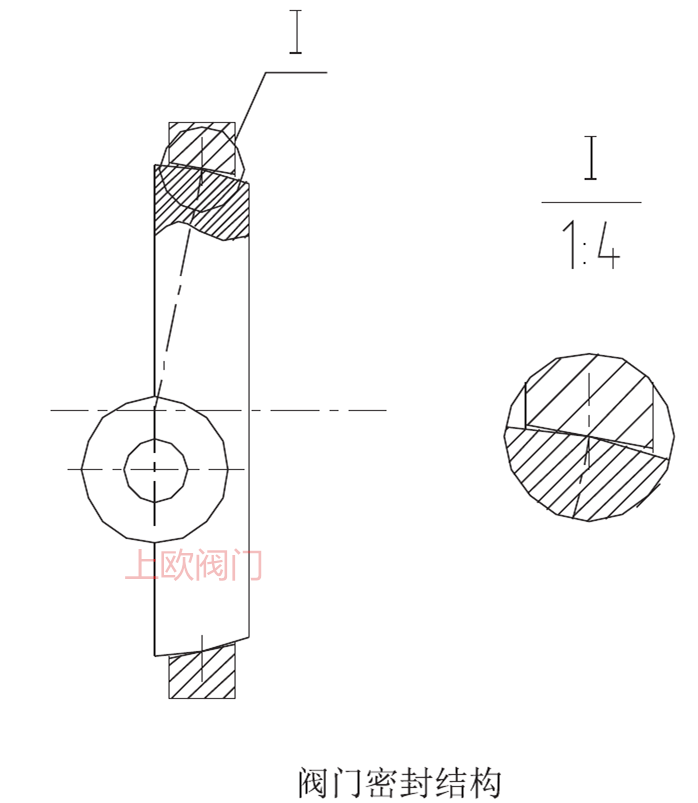

Working principle: the sealing surface of the valve core is cubic curved surface, and the sealing surface of the valve seat is a conical surface. At the sealing point, the seat surface is actually the section of the valve core cubic curved surface (see Figure), so its combination is perfect. It has the function of self-adaptive (center automatic positioning and reclosing) and wear compensation.

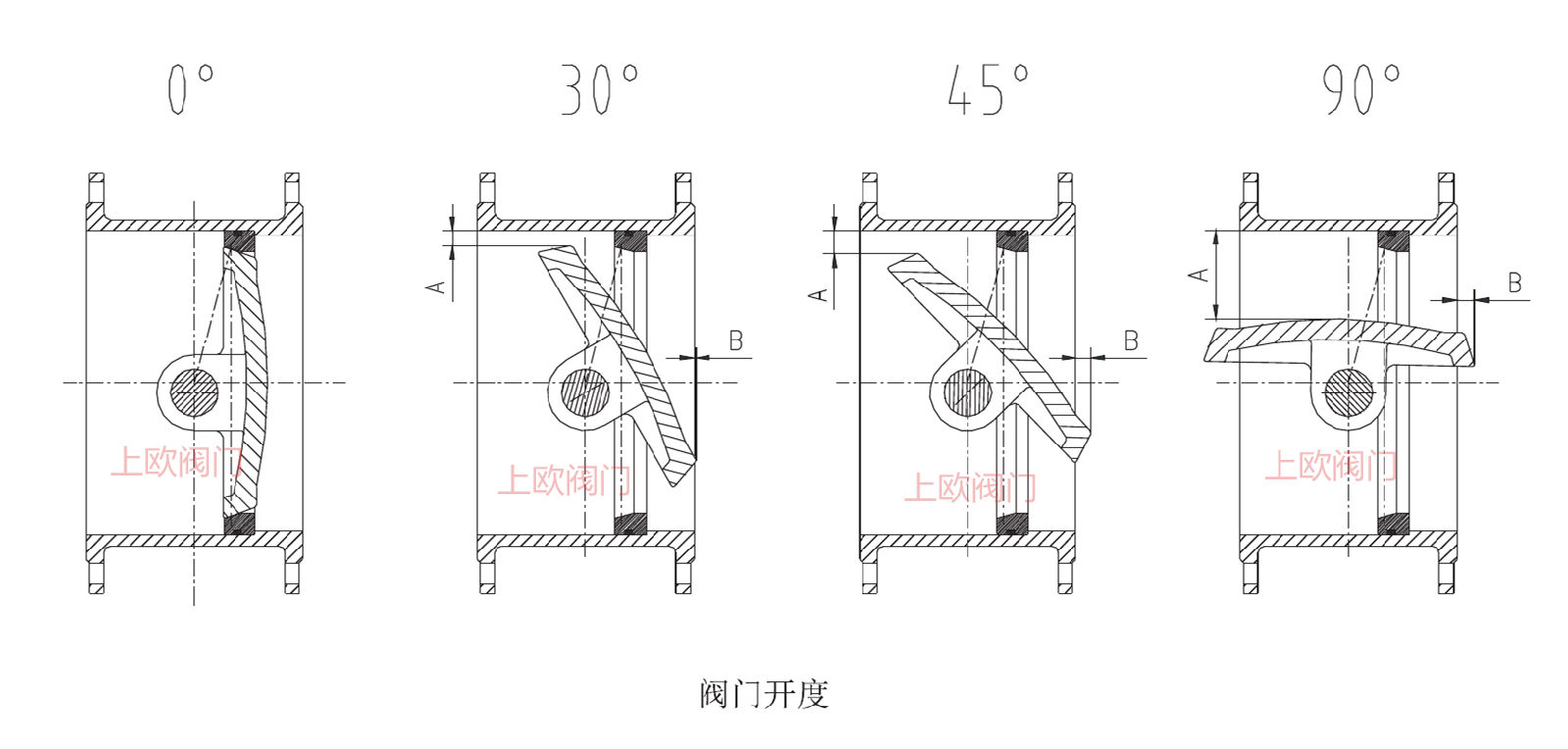

Because the rotation center deviates from the geometric center of the valve core, there will be the actual effect of the valve core body constantly moving backward and inward when the valve core is opened, and the valve core body is constantly moving forward and expanding outward when the valve core is closed. Its function is equivalent to the synthesis of hemispherical valve, gate valve, globe valve and butterfly valve. Open the change diagram of different angles:

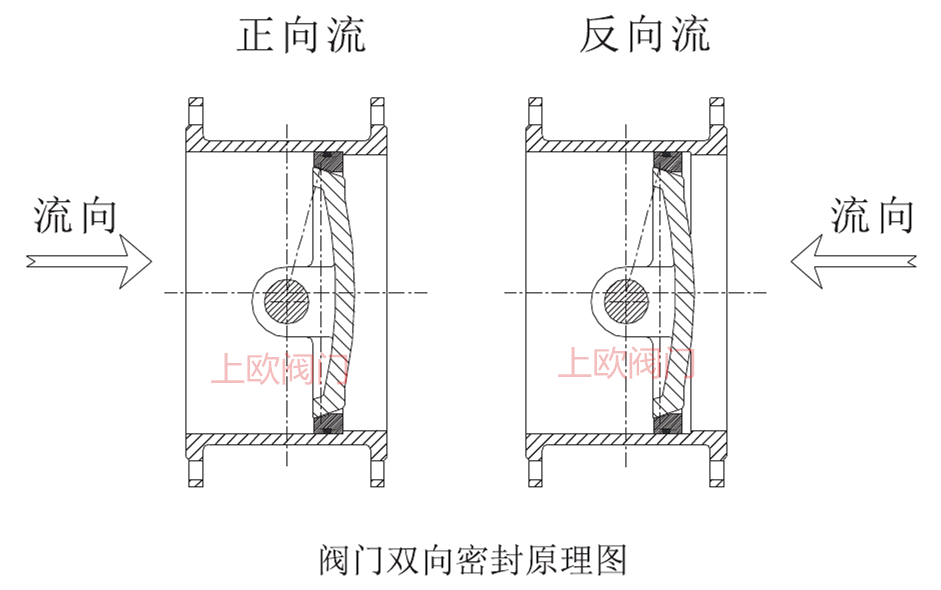

The main function of the two-way flow valve is that it can not only seal well under the forward pressure, but also seal well when the reverse pressure or the reverse pressure is greater than the positive pressure. When the positive pressure is applied, the medium pressure pushes the valve plate to move forward, and the valve rod is elastically deformed. The sealing surface of the valve plate is close to the sealing surface of the valve seat to transmit pressure and push the valve seat to the valve body step to make it well sealed. When the reverse pressure acts, the medium pressure pushes the valve plate to move backward, and the valve rod is elastically deformed. The medium pressure simultaneously pushes the valve seat to move backward, so that the sealing surface of the valve seat is close to the sealing surface of the valve plate, and the sealing specific pressure is maintained to make the valve seat seal well.

The main function of the two-way flow valve is that it can not only seal well under the forward pressure, but also seal well when the reverse pressure or the reverse pressure is greater than the positive pressure. When the positive pressure is applied, the medium pressure pushes the valve plate to move forward, and the valve rod is elastically deformed. The sealing surface of the valve plate is close to the sealing surface of the valve seat to transmit pressure and push the valve seat to the valve body step to make it well sealed. When the reverse pressure acts, the medium pressure pushes the valve plate to move backward, and the valve rod is elastically deformed. The medium pressure simultaneously pushes the valve seat to move backward, so that the sealing surface of the valve seat is close to the sealing surface of the valve plate, and the sealing specific pressure is maintained to make the valve seat seal well.

|

Valve diametermm) |

Electric fitting model |

Output speed(r/min) |

Motor power(KW) |

Motor current(A) |

|

150 |

DZW15 |

24 |

0.37 |

1.6 |

|

200 |

DZW20 |

18 |

0.37 |

1.6 |

|

250 |

DZW20 |

18 |

0.37 |

1.6 |

|

300 |

DZW30 |

18 |

0.55 |

2.4 |

|

350 |

DZW30 |

18 |

0.55 |

2.4 |

|

400 |

DZW45 |

24 |

1.1 |

3.4 |

|

450 |

DZW45 |

24 |

1.1 |

3.4 |

|

500 |

DZW60 |

24 |

1.5 |

4.5 |

|

600 |

DZW60 |

24 |

1.5 |

4.5 |

|

700 |

DZW90 |

24 |

2.2 |

6.5 |

|

800 |

DZW120 |

24 |

3 |

9 |

|

900 |

DZW120 |

24 |

3 |

9 |

|

1000 |

DZW120 |

24 |

3 |

9 |

|

1200 |

DZW180 |

24 |

4 |

11 |

|

1400 |

DZW250 |

24 |

5.5 |

14 |

|

1600 |

DZW350 |

18 |

7.5 |

19 |

|

1800 |

DZW350 |

18 |

7.5 |

19 |

|

2000 |

DZW500 |

18 |

10 |

26 |

The above are the electrical installation parameters of Changzhou Lanling valve control Co., Ltd. if the user needs to use the electric installation parameters of other companies, they can be replaced according to the above parameters. Three phase AC motor, 380V (special order 660 V or 220 V), 50 Hz (special order 60 Hz), can be selected according to user requirements.

0.6-1.0MPaConnection and installation dimension table of bidirectional hard seal ball valve

|

DN |

0.6MPa |

1.OMPa |

L |

H |

E |

H |

||||||||||

|

D |

D1 |

D2 |

N-d |

D |

D1 |

D2 |

N-d |

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | |||

|

150 |

265 |

225 |

199 |

8-18 |

285 |

240 |

211 |

8-22 |

140 |

175 |

280 |

355 |

315 |

555 |

800 |

705 |

|

200 |

320 |

280 |

254 |

8-18 |

340 |

295 |

266 |

8-22 |

152 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

|

250 |

375 |

335 |

309 |

12-18 |

395 |

350 |

319 |

12-22 |

165 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

|

300 |

440 |

395 |

363 |

12-22 |

445 |

400 |

370 |

12-22 |

178 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

|

350 |

490 |

445 |

413 |

12-22 |

505 |

460 |

429 |

16-22 |

190 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

|

400 |

540 |

495 |

463 |

16-22 |

565 |

515 |

480 |

16-26 |

216 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

|

450 |

595 |

550 |

518 |

16-22 |

615 |

565 |

530 |

20-26 |

222 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

|

500 |

645 |

600 |

568 |

20-22 |

670 |

620 |

582 |

20-26 |

229 |

380 |

580 |

650 |

714 |

1305 |

1290 |

1415 |

|

600 |

755 |

705 |

667 |

20-26 |

780 |

725 |

682 |

20-30 |

267 |

450 |

660 |

850 |

810 |

1340 |

1455 |

1605 |

|

700 |

860 |

810 |

772 |

24-26 |

895 |

840 |

794 |

24-30 |

292 |

|

800 |

975 |

920 |

878 |

24-30 |

1015 |

950 |

901 |

24-33 |

318 |

|

900 |

1075 |

1020 |

978 |

24-30 |

1115 |

1050 |

1001 |

28-33 |

330 |

|

1000 |

1175 |

1120 |

1078 |

28-30 |

1230 |

1160 |

1112 |

28-36 |

410 |

|

1200 |

1405 |

1340 |

1295 |

32-33 |

1455 |

1380 |

1328 |

32-39 |

470 |

|

1400 |

1630 |

1560 |

1510 |

36-36 |

1675 |

1590 |

1530 |

36-42 |

530 |

|

1600 |

1830 |

1760 |

1710 |

40-36 |

1915 |

1820 |

1750 |

40-48 |

600 |

|

1800 |

2045 |

1970 |

1918 |

44-39 |

2115 |

2020 |

1950 |

44-48 |

670 |

|

2000 |

2265 |

2180 |

2125 |

48-42 |

2325 |

2230 |

2150 |

48-48 |

760 |

|

2200 |

2485 |

2400 |

2340 |

52-42 |

2560 |

2440 |

2400 |

52-56 |

800 |

|

2400 |

2685 |

2600 |

2540 |

56-42 |

2760 |

2650 |

2610 |

56-56 |

850 |

|

2600 |

2905 |

2810 |

2740 |

60-48 |

2960 |

2850 |

2810 |

60-56 |

900 |

|

2800 |

3115 |

3020 |

2960 |

64-48 |

3180 |

3070 |

3030 |

64-56 |

950 |

|

480 |

550 |

850 |

810 |

1520 |

1585 |

1844 |

|

530 |

550 |

1250 |

810 |

1710 |

1700 |

2040 |

|

580 |

550 |

1250 |

863 |

1810 |

1965 |

2255 |

|

650 |

750 |

1250 |

863 |

1960 |

2015 |

2380 |

|

760 |

925 |

1250 |

863 |

2250 |

2250 |

2640 |

|

850 |

925 |

1250 |

1055 |

2434 |

2550 |

2866 |

|

1030 |

925 |

1250 |

1055 |

2780 |

2750 |

3156 |

|

1230 |

980 |

1250 |

1183 |

3020 |

2950 |

3421 |

|

1350 |

980 |

1500 |

1286 |

3270 |

3350 |

3685 |

|

1300 |

|

|

|

|

|

|

|

1400 |

|

|

|

|

|

|

|

1500 |

|

|

|

|

|

|

|

1610 |

|

|

|

|

|

|

|

3000 |

3315 |

3220 |

3160 |

68-48 |

3400 |

3290 |

3250 |

1.6-2.5MPaConnection and installation dimension table of bidirectional hard seal ball valve

|

DN |

1.6MPa |

2.5MPa |

L |

H |

E |

H |

||||||||||

|

D |

D1 |

D2 |

N-d |

D |

D1 |

D2 |

N-d |

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | |||

|

150 |

285 |

240 |

211 |

8-22 |

300 |

250 |

211 |

8-26 |

140 |

175 |

280 |

355 |

315 |

555 |

800 |

705 |

|

200 |

340 |

295 |

266 |

12-22 |

360 |

310 |

274 |

12-26 |

152 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

|

250 |

405 |

355 |

319 |

12-26 |

425 |

370 |

330 |

12-30 |

165 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

|

300 |

460 |

410 |

370 |

12-26 |

485 |

430 |

389 |

16-30 |

178 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

|

350 |

520 |

470 |

429 |

16-26 |

555 |

490 |

448 |

16-33 |

190 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

|

400 |

580 |

525 |

480 |

16-30 |

620 |

550 |

503 |

16-36 |

216 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

|

450 |

640 |

585 |

548 |

20-30 |

670 |

600 |

548 |

20-36 |

222 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

|

500 |

715 |

650 |

609 |

20-33 |

730 |

660 |

609 |

20-36 |

229 |

|

600 |

840 |

770 |

720 |

20-36 |

845 |

770 |

720 |

20-39 |

267 |

|

700 |

910 |

840 |

794 |

24-36 |

960 |

875 |

820 |

24-42 |

292 |

|

800 |

1025 |

950 |

901 |

24-39 |

1085 |

990 |

928 |

24-48 |

318 |

|

900 |

1125 |

1050 |

1001 |

28-39 |

1185 |

1090 |

1028 |

28-48 |

330 |

|

1000 |

1255 |

1170 |

1112 |

28-42 |

1320 |

1210 |

1140 |

28-55 |

410 |

|

1200 |

1485 |

1390 |

1328 |

32-48 |

1530 |

1420 |

1350 |

32-55 |

470 |

|

1400 |

1685 |

1590 |

1530 |

36-48 |

1755 |

1640 |

1560 |

36-60 |

530 |

|

1600 |

1930 |

1820 |

1750 |

40-55 |

1975 |

1860 |

1780 |

40-60 |

600 |

|

1800 |

2130 |

2020 |

1950 |

44-55 |

2195 |

2070 |

1985 |

44-68 |

670 |

|

2000 |

2345 |

2230 |

2150 |

48-60 |

2425 |

2300 |

2210 |

48-68 |

760 |

|

580 |

650 |

714 |

1305 |

1290 |

1415 |

|

660 |

850 |

810 |

1340 |

1455 |

1605 |

|

550 |

850 |

810 |

1520 |

1585 |

1844 |

|

550 |

1250 |

810 |

1710 |

1700 |

2040 |

|

550 |

1250 |

863 |

1810 |

1965 |

2255 |

|

750 |

1250 |

863 |

1960 |

2015 |

2380 |

|

925 |

1250 |

863 |

2250 |

2250 |

2640 |

|

925 |

1250 |

1055 |

2434 |

2550 |

2866 |

|

925 |

1250 |

1055 |

2780 |

2750 |

3156 |

|

980 |

1250 |

1183 |

3020 |

2950 |

3421 |

|

980 |

1500 |

1286 |

3270 |

3350 |

3685 |

4.0-6.3MPaConnection and installation dimension table of bidirectional hard seal ball valve

|

|

4.0MPa |

6.3MPa |

L |

H |

E |

H |

|||||||||||

|

D |

D1 |

D2 |

N-d |

D |

D1 |

D2 |

N-d |

Manual | Pneumatic | Electric | Manual | Pneumatic | Electric | ||||

|

150 |

300 |

250 |

211 |

8-26 |

345 |

280 |

211 |

8-33 |

140 |

175 |

280 |

355 |

315 |

555 |

800 |

705 |

|

|

200 |

375 |

320 |

284 |

12-30 |

415 |

345 |

284 |

12-36 |

152 |

200 |

425 |

250 |

315 |

760 |

850 |

775 |

|

|

250 |

450 |

385 |

345 |

12-33 |

470 |

400 |

345 |

12-36 |

165 |

230 |

425 |

250 |

315 |

830 |

925 |

945 |

|

|

300 |

515 |

450 |

409 |

16-33 |

530 |

460 |

409 |

16-36 |

178 |

260 |

560 |

450 |

315 |

895 |

1035 |

1070 |

|

|

350 |

580 |

510 |

465 |

16-36 |

600 |

525 |

465 |

16-39 |

190 |

300 |

560 |

450 |

315 |

950 |

1070 |

1140 |

|

|

400 |

660 |

585 |

535 |

16-39 |

670 |

585 |

535 |

16-42 |

216 |

340 |

580 |

450 |

315 |

1190 |

1190 |

1210 |

|

|

450 |

685 |

610 |

560 |

20-39 |

|

|

|

|

222 |

350 |

580 |

650 |

714 |

1255 |

1250 |

1335 |

|

|

500 |

755 |

670 |

615 |

20-42 |

|

|

|

|

229 |

380 |

580 |

650 |

714 |

|

600 |

890 |

795 |

735 |

20-48 |

|

|

|

|

267 |

450 |

660 |

850 |

810 |

Note: for other pressure levels, please consult the technical department of the company. Different connection standards can be designed and produced according to user requirements.

Due to product improvement, there may be differences between the material object and the publicity materials. The company reserves the right to interpret the above data. Please contact the company's technical department when ordering specific parameters.

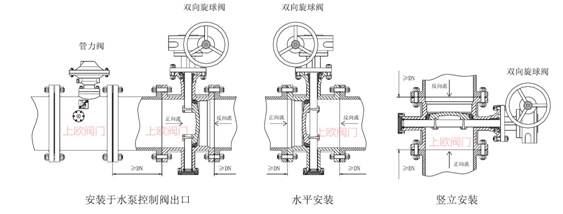

1) There shall be no reduction, elbow, bellows, etc. on the pipes within 0.5dn length before and after the installation;

2) If butterfly valve, pipe force valve, butterfly check valve or butterfly slow closing check valve are installed immediately before and after the valve, the distance between two adjacent valves is 1.0dn;

3) During assembly, installation, transportation, maintenance and repair or disassembly of valve plate, pay attention not to touch the sealing surface and take strict protection measures;

4) The valve plate shall be closed during assembly, transportation, installation and storage;

5) If it is necessary to disassemble, pay attention not to damage the shaft sleeve to prevent the loss of taper pin and shaft sleeve;

6) After assembly, installation, maintenance and repair, the metal chips, dirt and impurities in the valve shall be removed, and the sealing surface of surfacing welding shall be wiped clean;

7) Regardless of horizontal or vertical installation, when the flow direction cannot be determined, when the valve is opened, the butterfly valve has a large face and the end is facing the inlet direction;

8) If it is not used for a long time, please coat the sealing surface with grease or oil paper, and cover the sealing surface with wax paper.

| Two way hard seal ball valve | Soft seal center line butterfly valve | Multi level butterfly valve | Two way flow butterfly valve with elastic plate | Eccentric hemisphere valve |

|

1、It can be reliably sealed in both directions and can meet the national pressure test standard |

It can be pressurized in both directions and sealed by rubber deformation at the edge | It can't be sealed in both directions. When the reverse direction reaches 0.1-0.3mpa, it will open automatically and leak water | It can be bi-directional, but long-term reverse will cause permanent deformation and failure | Can't double direction, reverse automatic opening, water leakage |

|

2、The sealing surface of valve seat and valve core can be made into high hard sealing surface |

At least one side of valve seat or valve plate is rubber soft seal | At least one side of valve seat or valve plate is rubber soft seal | - the edge is a fully formed stainless steel elastic sheet, | Both sides can be stacked hard, but if the sphere is too hard, it is difficult to ensure the machining accuracy |

|

3、It has the function of sealing automatic compensation after wear |

Once the rubber is worn and damaged, the seal will be invalid | It can't be compensated. It will shrink and leak when it is touched by many layers | If the elastic plate is worn, it will fail | It can be compensated |

|

4、When closing, it can cut off the long strip impurities and eliminate the granular impurities |

High hard impurities will damage the seal | Impurities will destroy the graphite part of the multilayer structure and make the seal invalid | The strength of the elastic sheet is low and easy to be destroyed by impurities | When closing, it can cut off the long strip impurities and eliminate the granular impurities |

|

5、There is no friction between the sealing surface of valve core and valve seat when closing |

It's completely rubbed into the seal | High precision three eccentric without friction, otherwise there is friction | The friction is very serious | There is no friction between the sealing surface of valve core and valve seat when closing |

|

4、When closing, it can cut off the long strip impurities and eliminate the granular impurities |

High hard impurities will damage the seal | Impurities will destroy the graphite part of the multilayer structure and make the seal invalid | The strength of the elastic sheet is low and easy to be destroyed by impurities | When closing, it can cut off the long strip impurities and eliminate the granular impurities |

|

5、There is no friction between the sealing surface of valve core and valve seat when closing |

It's completely rubbed into the seal | High precision three eccentric without friction, otherwise there is friction | The friction is very serious | There is no friction between the sealing surface of valve core and valve seat when closing |

|

6、The structure is short in length and light in weight. It can be made into large diameter valve |

The structure is short in length and light in weight. It can be made into valve with caliber | The structure is short in length and light in weight. It can be made into valve with caliber | The structure is short in length and light in weight. It can be made into large diameter valve | Long structure, heavy weight, can not be made into large diameter valve |

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website