Telephone:

0577-67975099

Location:Home > Product Center > Hydraulic Control Valve > BFDS Multi function hydraulic control valve

Location:Home > Product Center > Hydraulic Control Valve > BFDS Multi function hydraulic control valve

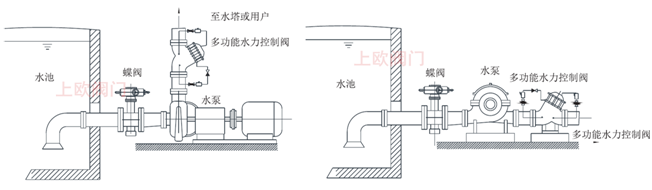

Multifunctional piston hydraulic control valve is a patented product of our company. It has the characteristics of hydraulic automatic control, slow opening when starting the pump, fast closing first and then slow closing when stopping the pump. It has the functions of check-in and elimination of water hammer. It is suitable for supporting automatic water supply and drainage control system to effectively improve the safety and reliability of water supply.

Multifunctional piston hydraulic control valve is a patented product of our company. It has the characteristics of hydraulic automatic control, slow opening when starting the pump, fast closing first and then slow closing when stopping the pump. It has the functions of check-in and elimination of water hammer. It is suitable for supporting automatic water supply and drainage control system to effectively improve the safety and reliability of water supply.

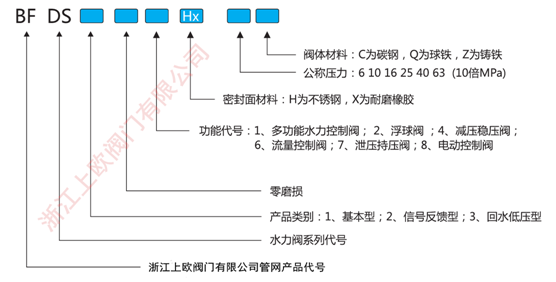

Model example:

|

BFDS101HX-16C |

Multi function hydraulic control valve 1.6 MPa cast steel valve body hard and soft double sealing |

|

BFDS201HX-25C |

Signal type multifunctional hydraulic valve 2.5 MPa cast steel valve body with soft and hard double sealing |

|

BFDS102HX-10Q |

Floating ball valve 1.0 MPa ductile iron valve body hard and soft double sealing |

|

BFDS104HX-6Q |

Pressure reducing and stabilizing valve 0.6 MPa ductile iron valve body soft and hard double sealing |

|

BFDS107HX-10Z |

Pressure relief and pressure holding valve 1.6 MPa cast iron valve body with soft and hard double sealing |

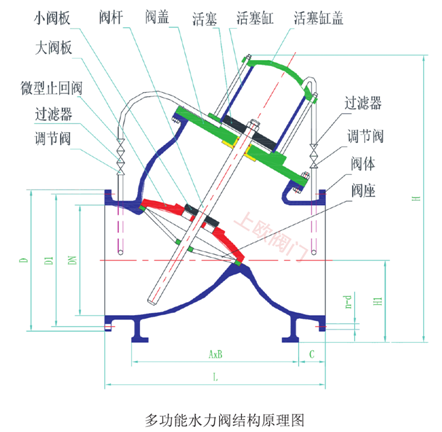

1) Basic structure:

It is composed of main valve and external control components. The main valve is composed of valve body, large and small valve plates, valve stem, valve cover, valve seat, piston and piston cylinder. The external control components are composed of micro check valve, regulating valve, filter and corresponding pipeline. In the external control assembly, one channel connects the inlet end of the valve with the lower chamber of the piston cylinder, and the other connects the outlet end of the valve with the upper chamber of the piston cylinder

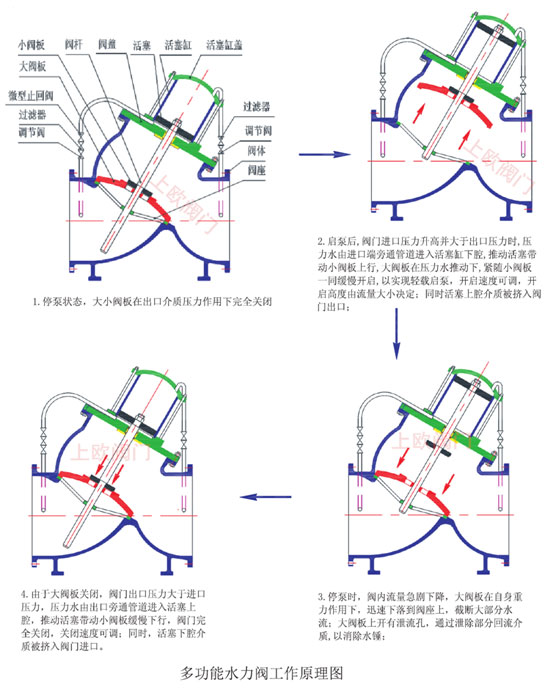

2) Working principle:

The opening and closing of the valve depends on the pressure of the delivered medium and the pressure difference in the piston cylinder. The action time is controlled by the control valve in the external control module. The opening and closing of the valve is completed by large and small valve plates. The large valve plate plays the role of fast opening and closing, and the small valve plate plays the function of slow opening and closing. It should be noted that the opening of the large valve plate is controlled by the small valve plate. Only when the small valve plate acts, the large valve plate can act.

After starting the pump, the medium enters the lower chamber of the piston cylinder through the external control parts, and the piston moves up to drive the small valve plate to rise, which releases the axial constraint on the large valve plate, and the large valve plate opens under the effect of the inlet medium pressure.

When the inlet pressure disappears, the large valve plate will drop rapidly under the action of the medium pressure at the valve outlet end and the self weight to realize quick closing and intercept most of the fluid. At the same time, the pressure in the upper chamber of the piston cylinder pushes the piston down to realize the slow closing of the small valve plate. Because the external control circuit is equipped with regulating valve, the speed of piston moving up and down in the piston cylinder can be adjusted, so as to realize the regulation of the slow opening and closing process of the valve plate.

By changing the opening of the control valve in the external control module, the time of valve opening and closing can be adjusted. The filter has the function of reverse self cleaning, which greatly improves the reliability of the product and the service life of the product.

工作原理:

The work of the multi-function hydraulic valve is driven by the pressure water in the pipe network. It is controlled automatically by the pressure water and the pump, without manual intervention.

引用但不限于以下标准,未注日期的引用文件,其最新版本适用于本产品。

| Standard name | Standard number | |

| Integral steel pipe flange |

GB/T 9113.1-9113.26-2010 |

|

| Flanged metal valves | Flanged metal valves |

GB/T 12221 |

| General purpose valves | Pressure test |

GB/T 13927 |

| Dimensions of integral cast iron pipe flange |

GB/T 17241.6 |

|

|

通用阀门 |

供货要求 |

GB/T 12252 |

|

BFDS型多功能水力控制阀(上欧阀门企业标准) |

Q/QPJF001 |

|

|

阀门铸钢件 |

外观质量要求 |

JB/T 7927-1999 |

|

通用阀门 |

材料 |

JB/T 5300-2008 |

|

通用阀门 |

球墨铸铁瓶术条件 |

GB/T 12227 |

|

通用阀门 |

碳素钢铸瓶术条件 |

GB/T 12229 |

| Serial number | name | texture of material | Serial number | name | name | texture of material | |

|

1 |

valve body | Cast iron, ductile iron and cast steel |

6 |

Control chamber cover | Cast iron, ductile iron and cast steel | ||

|

2 |

Valve shaft | Stainless steel |

7 |

Control chamber base | Cast iron, ductile iron and cast steel | ||

|

3 |

Large valve plate | cast steel |

8 |

Bypass fitting | Stainless steel, copper pipe, RiFeng pipe | ||

|

4 |

Small valve plate | Stainless steel |

9 |

axle sleeve |

Tin bronze ZCuSnlOZn2 |

||

|

5 |

piston | Stainless steel |

10 |

Sealing element |

Nitrile rubberNBR |

|

Nominal diameter(mm) |

50-1000 |

|

Nominal pressure(MPa ) |

0.6、1.0、1.6、2.5、4.0、6.3 |

| Leakage | Meet the requirements of GB / t13927 |

| Minimum operating pressure |

0.05MPa |

|

Applicable temperature(。C) |

0~80oC |

1) It has many functions, such as light load pump start, cut-off check, elimination of water hammer and so on.

2) The valve can be equipped with opening indicator rod, and the stroke of piston cylinder can be controlled by adjusting the screw rod to realize the coarse flow regulation; and the travel switch or valve position indicator can be installed to output the switch signal or 4-20mA DC power for monitoring in the main control room (the company's patent).

3) The opening and closing of the valve is driven by the conveying medium and is automatically interlocked with the operation of the water pump. The valve of the pump is opened and the stop valve of the pump is closed. It is very convenient to operate the valve without personnel. It does not need external power and components, with less faults and less maintenance.

4) When the valve is fully open, its resistance coefficient is basically the same as that of Y-type stop valve, and the resistance loss is reduced by about 20% compared with similar products at home and abroad.

5) The filter in the external control channel has the function of self flushing, which can effectively adapt to the polluted medium and prolong the service life of the valve.

6) The drive and control parts are located outside the valve body, so the internal parts of the valve piston cylinder can be repaired online without stopping the pump.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....test

Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website