Telephone:

0577-67975099

Location:Home > Product Center > Butterfly Valve > D971X-10Double clip butterfly valve with electric switch

Location:Home > Product Center > Butterfly Valve > D971X-10Double clip butterfly valve with electric switch

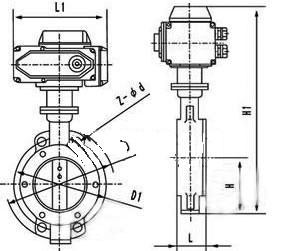

D971X-10The double clip butterfly valve is composed of angle stroke electric actuator and butterfly valve. The switch type electric butterfly valve is directly connected to the power supply (AC220V or other power level power supply), and the switch action is completed through the switch forward and reverse guidance.

D971X-10The double clip butterfly valve is composed of angle stroke electric actuator and butterfly valve. The switch type electric butterfly valve is directly connected to the power supply (AC220V or other power level power supply), and the switch action is completed through the switch forward and reverse guidance. The electric switch butterfly valve has the advantages of simple structure, small size, light weight, convenient and quick opening and closing, labor saving, small fluid resistance and large flow capacity. For normal temperature and clean media, valve plate and soft seal (rubber ring and tetrafluoroethylene ring) can be selected to reduce leakage (up to 0.01%). Three eccentric hard sealing valve body can be selected for high temperature and high pressure working conditions. It can be indicated when ordering. It can be widely used in food, environmental protection, light industry, petroleum, chemical industry, teaching equipment, papermaking, electric power and other industries of industrial process automatic control system.

| Design criteria | GB/T2238-1989 |

|---|---|

| Flange connection size | GB/T9113.1-2000;GB/T9115.1-2000;JB78 |

| Structural length | GB/T12221-1989 |

| Pressure test | GB/T13927-2000;JB/T9092-1999 |

D971X-10Materials of main parts and components of type-A electric switch wafer butterfly valve

| Part name | Material Science |

|---|---|

| valve body | Nodular cast steel, cast steel, alloy steel, stainless steel |

| Disc | Gray cast iron, nodular cast steel, cast steel, stainless steel and special materials |

| seal ring | All kinds of rubber, PTFE, stainless steel |

| Stem | 2Cr13、stainless steel |

| filler | O-ring, flexible graphite |

1. Before installation, check whether the specification, pressure, temperature and corrosion resistance of butterfly valve meet the use requirements. Check whether the parts are damaged or loose.

2. The butterfly valve can be installed on the pipeline at any angle and should be closed; when welding the pipe flange, the valve sealing port should be blocked with a plate to prevent particles and sundries from damaging the sealing surface. After welding, take down the valve, clean the valve sealing surface and pipe cavity, and then install the fixed valve.

3. Please pay attention to the pressure bearing direction when the valve is closed.

4. Before installation, the sealing surface (sealing surface at both ends, sealing surface of butterfly plate and sealing surface of valve seat) shall be thoroughly cleaned to remove dust and dirt.

5. Before installation, the butterfly valve should be air tested, and the opening and closing position should be flexible, and the opening and closing position should be consistent with the position indicated by the pointer.

6. Manual operation, clockwise is off, counter clockwise is on, pointer indication is in place, it is not allowed to open and close the valve with additional force.

7. During the pressure test of the valve, it is not allowed to use single flange for installation and pressure test, but double flange installation and pressure test must be adopted. The test pressure shall comply with GB / T13927-92.

8. The bolts shall be tightened symmetrically and alternately instead of separately.

9. The limit screw has been adjusted before delivery, so it is not allowed to adjust it easily. If the configuration of driving device is electric or pneumatic, please refer to the manual of supporting drive device.

10. When the electric butterfly valve leaves the factory, the opening and closing stroke of the control mechanism has been adjusted. In order to prevent the wrong direction when the power supply is connected, the user should first manually open it to the half open position before connecting the power for the first time, and then press the inching switch to check that the direction of the indicator wheel is consistent with the opening direction of the valve.

11. If the valve is found to be open and closed abnormally, the cause shall be found out for repair and elimination, so as to prevent the valve from being damaged due to opening and closing by means of applying force.

蝶阀的产品分类介绍

蝶阀又叫翻板阀,是一种结构简单的调节阀,同时也可用于低压管道.....常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website