Telephone:

0577-67975099

Location:Home > Product Center > Butterfly Valve > SD341XExpansion flange butterfly valve

Location:Home > Product Center > Butterfly Valve > SD341XExpansion flange butterfly valve

The butterfly valve can be axially retracted in a certain range, and can also overcome the offset caused by the pipe docking with different shafts in a certain angle range. It has automatic compensation for the thermal expansion and cold contraction of the pipeline, which greatly facilitates the installation and disassembly of the valve pipeline. It can be used in petroleum, chemical, electric power, papermaking, food, beverage, pharmaceutical pure pipeline and industrial environmental protection, water treatment, high-rise building, water supply and drainage pipeline for opening and closing or regulating medium flow with temperature below 425 ℃ and nominal pressure below 1.6Mpa. The valve drive mode has worm gear manual, pneumatic and electric.

SD341XExpansion flange butterfly valve is used in petroleum, metallurgy, chemical industry, electric power, medicine, food, light textile, ship, municipal engineering and water supply and drainage system. It is suitable for the general corrosive, non corrosive gas, liquid, semi fluid, solid powder and other media for closure and regulation control. It can also be used for the transformation of old pipelines, maintenance and replacement of matching valves.

|

Nominal pressure PN(Mpa) |

Test pressureMPa |

working pressure MPa |

working temperature (℃) |

|

| seal up | strength | |||

|

1.0(10) |

1.1 |

1.5 |

1.0 |

-46℃-135℃ |

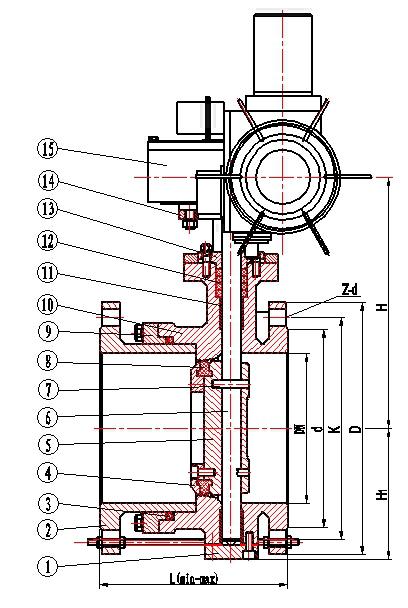

SD341XThe expansion flange butterfly valve is a flange connection. Its main feature is that the structure length can be expanded and extended, which is conducive to be installed on the long pipe to absorb the heat expansion and cold contraction or balance the vibration influence of the pipeline. Because of the long expansion space, the expansion device is omitted. The valve adopts rubber soft seal with good sealing performance, and has the characteristics of simple structure, light weight, short connection size, large flow rate, small liquid resistance and convenient maintenance.

The main parts of the valve are valve body, expansion pipe, butterfly plate, sealing ring, valve stem and actuator. When using, rotate the hand wheel clockwise to close and counterclockwise to open.

| Part name | Material Science | Part name | Material Science |

|

valve body |

Cast iron / cast steel | Sealing ring pressing plate |

Q235 |

|

Telescopic tube |

Cast iron / cast steel |

Stem |

2Cr13, 45 |

|

Disc |

Cast iron / cast steel |

seal ring |

Oil resistant rubber |

SD341X-10、SD941X-10 Main dimensions:

| Specifications |

minimum L1 |

middle L |

Longest L2 |

D |

D1 |

D2 |

H1 |

H2 |

Z-φd |

|

100 |

174 |

195 |

216 |

215 |

180 |

155 |

110 |

170 |

8-φ18 |

|

125 |

186 |

209 |

232 |

245 |

210 |

185 |

123 |

185 |

8-φ18 |

|

150 |

194 |

216 |

239 |

280 |

240 |

210 |

140 |

210 |

8-φ23 |

|

200 |

214 |

239 |

264 |

335 |

295 |

265 |

170 |

238 |

8-φ23 |

|

250 |

260 |

276 |

296 |

390 |

350 |

320 |

195 |

270 |

12-φ23 |

|

300 |

250 |

275 |

300 |

440 |

400 |

368 |

222 |

300 |

12-φ23 |

|

350 |

270 |

295 |

320 |

500 |

460 |

428 |

252 |

330 |

16-φ23 |

|

400 |

280 |

307 |

330 |

565 |

515 |

482 |

285 |

368 |

16-φ25 |

|

450 |

305 |

330 |

355 |

615 |

565 |

532 |

310 |

402 |

20-φ25 |

|

500 |

315 |

340 |

365 |

670 |

620 |

585 |

337 |

438 |

20-φ25 |

|

600 |

370 |

395 |

420 |

780 |

725 |

685 |

393 |

490 |

20-φ30 |

|

700 |

396 |

421 |

446 |

895 |

840 |

800 |

450 |

558 |

24-φ30 |

|

800 |

426 |

451 |

476 |

1010 |

950 |

905 |

515 |

625 |

24-φ34 |

|

900 |

456 |

481 |

506 |

1110 |

1050 |

1005 |

560 |

685 |

28-φ34 |

|

1000 |

466 |

491 |

516 |

1220 |

1160 |

1115 |

610 |

750 |

28-φ34 |

|

1200 |

510 |

535 |

560 |

1450 |

1380 |

1325 |

725 |

880 |

32-φ41 |

|

1400 |

540 |

565 |

590 |

1675 |

1590 |

1525 |

840 |

987 |

36-φ48 |

|

1600 |

585 |

608 |

630 |

1915 |

1820 |

1750 |

960 |

1158 |

40-φ54 |

|

1800 |

630 |

655 |

680 |

2115 |

2020 |

1950 |

1060 |

1258 |

44-φ54 |

|

2000 |

680 |

705 |

730 |

2325 |

2230 |

2160 |

1165 |

1365 |

48-φ54 |

| Possible faults | Cause | resolvent |

| Packing leakage |

|

|

| Leakage at the joint of valve body and nozzle |

|

|

| Leakage of sealing surface | 1.There are impurities on the sealing surface 2.Wear of sealing ring 3.The pressing plate is loose |

|

| Replacement of packing |

|

|

用户If there are special requirements, it should be stated at the time of ordering. Our factory can design and produce again according to the user's requirements.

蝶阀的产品分类介绍

蝶阀又叫翻板阀,是一种结构简单的调节阀,同时也可用于低压管道.....常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website