Telephone:

0577-67975099

Location:Home > Product Center > Hydraulic Control Valve > BFDGPipe force valve

Location:Home > Product Center > Hydraulic Control Valve > BFDGPipe force valve

BFDGDiaphragm type pipe force valve and piston type pipe force valve are the latest pump outlet control valves developed by our company for five years. They are the third generation of new butterfly type multi-function pump control valves following the old manual control valve, hydraulic control butterfly valve and hydraulic control valve. The valve adopts advanced fluid design, with low energy consumption, stable operation and good sealing effect. It has the functions of electric gate valve, electric butterfly valve and check valve. Its quick closing speed and adjustable pressure relief time can effectively eliminate the harm of water hammer and protect the safety of water pump and pipe network system.

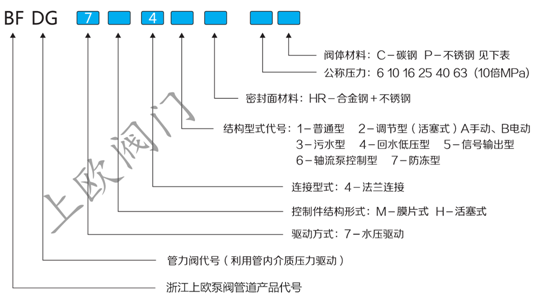

Model example

Bfdg7m43hr-10c cast steel diaphragm sewage type flange connection pipe force valve bfdg7h42ahr-40c

Note: diaphragm structure is adopted for basic type; diaphragm structure is recommended for sewage type; piston structure is selected for regulating type.

Comparison table of commonly used valve body and valve plate materials

| Material name | Material grade | Main media |

|

|

ANSI/ASTstandard |

G B |

||

| carbon steel |

WCB |

ZG25 |

Main media |

| Ni Cr cast iron |

\ |

QT400Ni2Cr |

seawater |

|

CF8 (304) |

ZGlCrl8Ni9TiZGlCrl8Nil2Mo2Ti |

Corrosive media such as nitric acid | |

| Cr Ni Mo stainless steel |

CF8M (316) |

Acetic acid corrosive medium | |

| Cr Ni ultra low carbon stainless steel |

CF3(304L) |

Corrosive media such as nitric acid | |

| Cr Ni Mo ultra low carbon stainless steel |

CF3M(316L) |

Acetic acid corrosive medium |

The latest version of undated reference documents is applicable to this product.

| Standard content | Standard number | Standard name |

| Enterprise standard |

Q/OPJF007-2012 |

BFDGPipe force control valve |

| Design and manufacturing standards |

GB/T12236 |

Butterfly Check Valve |

|

API6D |

Butterfly check valve with damping | |

|

GB/T13927-2008 |

Pressure test for general purpose valves | |

| Flange standard |

GB9113.1-9113.4 |

Integral steel flange / customer specified standard |

| Structural length standard |

GB/T12221 |

Metal valve structure length |

| Standard of materials used |

GB/T12229 |

Technical specification of carbon steel castings for general purpose valves |

|

GB/T12230 |

Technical specification of austenitic copper castings for general purpose valves |

| project | caliber | ||

|

|

< 1000mm |

≥1000mm |

|

|

Valve closing time(s) |

fast |

1~2.5 |

1〜5 |

|

|

slow |

3〜60 |

5-90 |

|

(Mpa) |

=0.05 |

||

| resistance coefficient |

0.3〜1.1 |

||

| Valve opening time |

10-60 |

||

| Water hammer peak |

S 1.5Double the rated pressure of water pump outlet |

||

| Maximum reverse speed of water pump |

S 1.2Double the rated speed of water pump |

||

| Adaptive temperature |

Not indicated as 0-80 ° C, can produce - 25 ° C-200 ° C |

||

1. Various functions: it has the functions of closure check, light load pump starting, eliminating water hammer, etc., and one valve with multiple valves can save the total investment of equipment.

2. Slowly open the pump: after starting the pump, under the action of the microporous check valve at the inlet end, the valve can only be opened after reaching a constant pressure, which can reduce the pump starting current and ensure the safety of the motor and electric control system.

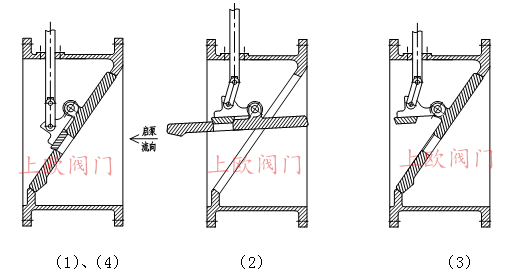

3. Quick closing and slow closing: unique small valve plate structure (patent of our company 200720064765.7 "slow closing structure of small valve plate of pipe force control valve"), when stopping the pump, fast closing and then slow closing can effectively eliminate water hammer and ensure system safety.

4. Beautiful appearance: the innovative design of control device is adopted in the structure, with small external space, simple internal structure and strong operation reliability. In terms of technology, the shell and parts are precision casting, with good structural strength and simple and exquisite appearance.

5. Easy to install: butterfly valve structure, small size, light weight, small space, reduce the cost of civil engineering, can be applied to various installation methods such as surface and trench.

6. Simple maintenance: the opening and closing of the valve is driven by the conveying medium, which is automatically interlocked with the water pump, without manual and external force operation; there is no external power and components, and the integrated structure has less fault points; the parts and components in the hydraulic cylinder can be overhauled at the same time of the normal operation of the unit; the key parts are made of high-quality materials, basically without maintenance; The filter in the external control channel has the function of self washing

7. Energy saving and consumption reduction: the opening and closing parts are inclined butterfly plate, the water flow is smooth, and the loss along the way and local loss is very small; cancel the electro-hydraulic control system of hydraulic butterfly valve, reduce the cost, increase the reliability and stability, reduce the power consumption, and achieve the purpose of energy saving.

8. Reliable operation and sealing: it adopts the soft and hard double sealing structure (the patent of zl01249431.3 "soft and hard combined sealing device for valve opening and closing parts") or metal hard sealing structure,

The friction moment of the sealing pair is very small; the oblique eccentric structure seal pair shortens the valve closing stroke, reduces the slip distance of the seal ring, reduces the friction torque, achieves the effect of instantaneous clutch, and has the function of anti sediment and automatic pressure compensation; the optimized design of the sealing angle of the valve body and valve plate makes the valve opening and closing flexible and reliable.

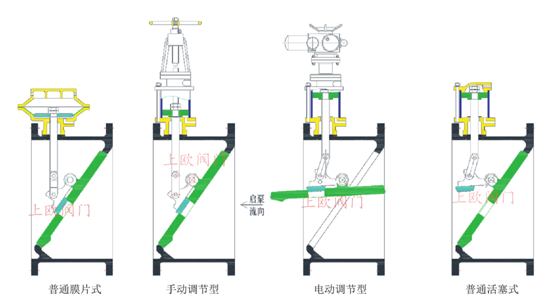

9. Strong adaptability: the products are diaphragm type and piston type, which are suitable for various working conditions and media. The special filter in the external control unit can effectively filter the impurity particles in the sewage, and ensure that the medium entering the diaphragm cavity or piston cylinder is clean liquid. The filter device has the function of self washing, and the bypass inlet end is equipped with a slag discharge device, which can manually and regularly discharge slag. The adjustable type can adjust the flow rate by manual or electric control according to the working conditions.

Figure 2 product types

4. Bfdg 7m / h 44 backwater low pressure type is recommended when the return water pressure of pipe network system is lower than o.lmpa. The valve is equipped with auxiliary valve closing mechanism.

5. The working principle of bfdg 7m / h 4.5 signal output type pipe force valve is the same as that of ordinary type. On the basis of the valve, a travel switch is added to directly express three kinds of signals: full open, full close and fault. The opening and closing conditions of the valve can be observed locally or remotely. The device has simple structure and convenient operation and maintenance.

6. Bfdg 7m / h 4.6 axial flow pump is designed for the working characteristics of axial flow pump. By adding control components, the valve can realize the function of light load pump starting by opening the valve first and then starting the pump. When the pump is stopped, the valve will automatically close quickly and then slowly to eliminate the valve closing water hammer.

7. The bfdg 7m / h 47 antifreeze type is suitable for the northern and other cold climate areas. The control part of the antifreeze type pipe force valve adopts heat preservation structure. Through heat exchange, auxiliary heating and other forms, it can be applied to the harsh working condition of - 20 ℃.

name

| Common material | Chromium nickel stainless steel | Seawater resistant material | |

| Valve shaft |

Stainless steel2Crl3 |

ZGlCrl8Ni9Ti |

316L |

| Diaphragm / piston | NBR / stainless steel |

EPDM/2Crl3 |

EPDM/316L |

| Sealing surface of valve body |

ZGlCrl8Ni9Ti |

ZcuZn38Mn2Pb2 |

|

| Hard seal pair |

D507(H)+A102(R) |

316L+316L |

T+316L |

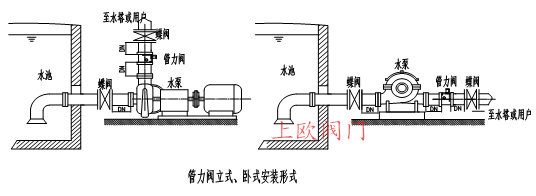

1. The pipe force valve can be installed horizontally and vertically (the medium flow direction is upward). The top rod side of the control cylinder is the outlet direction. Reverse installation is strictly prohibited. The valve shaft must be in the horizontal position.

2. In order to facilitate installation and maintenance, horizontal installation should be given priority when space permits.

3. When the valve diameter is greater than or equal to 900mm, support or foundation can be set to improve the stress condition of pipeline.

When installing butterfly valve behind 4 valve, the installation distance is usually 1DN. Please contact the company's technical department for more detailed installation dimensions before and after the valve of each caliber.

| Main valve structure | Control cavity form | Position of control chamber | Operating mode of valve plate | Sealing form | Pressure relief form | |

| Swing check valve | Butterfly or swing structure | Slow closing piston cylinder | In flow channel or one side of valve body | Swing structure | The cast iron surface is lined with rubber, It is in the form of soft sealing |

There is no drain hole, and the discharge depends on the buffer piston (slow closing adjustment is poor, easy to damage, easy to generate noise, unable to eliminate the hidden danger of water hammer) |

| Lifting return valve | Cut off structure | nothing | nothing |

Lift type operation, when closing the valve, the |

There are soft seal and hard Two forms of sealing structure |

No slow opening and closing function |

| Pipe force valve | Butterfly structure | Piston type, diaphragm type | Overhead | Screw in structure and large valve The plate is equipped with buffer device to close the valve Silent sound |

Hard and soft double seal | Fast closing of large valve plate, slow closing of small valve plate and two-stage closing of valve |

| comparative analysis | Butterfly structure is small in size, Light weight, in resources The trend of increasing tension Next, butterfly style is the mainstream hair Exhibition form. |

The pipe force valve is realized through the control chamber Slow opening and closing function. also A variety of control cavity forms are available According to different working conditions, medium and pressure power. |

Pipe force valve overhead control chamber The structure does not occupy the channel space The resistance coefficient is small, And convenient for maintenance and safety Can be installed on the ground Surface, trench, etc., none The original civil works need to be changed Facilities. |

The moment of inertia of tube force valve plate is small, |

Hard and soft double sealing surface, The combination of hard sealing structure is strong High strength, wear resistance, wear resistance Impact and soft seal seals It has the advantages of good performance Effective solution to the valve tightness Sealing problem can ensure the valve Long term "zero leakage" of door |

The large valve plate is hung independently, and The large valve plate is provided with a drain hole, Make sure the pump is stopped under any condition Now the large valve plate is closed to prevent water pump High speed reversal and its discharge hole Dynamic pressure relief to prevent water hammer accidents happen. |

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....test

Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website