Telephone:

0577-67975099

Location:Home > Product Center > Plug Valve > Piston type multifunctional electric control valve

Location:Home > Product Center > Plug Valve > Piston type multifunctional electric control valve

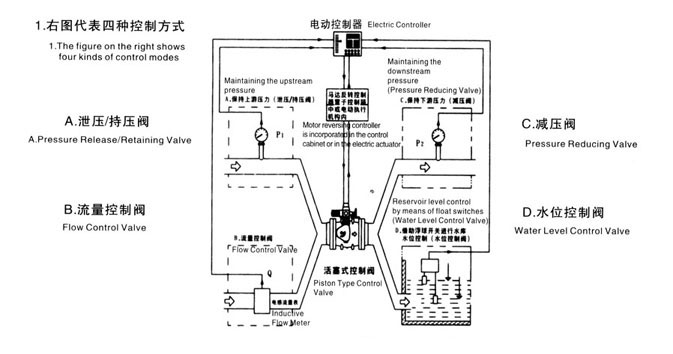

The piston type multi-functional electric control valve is of piston structure, the regulating mechanism of piston type control valve shall be crank slider mechanism, and the sliding block of closing part shall be cylindrical or conical piston. The inner cylinder of the valve body can move axially along the center of the pipeline under the guide of the guide rail, thus changing the area of the flow passage to realize the function of regulating the flow rate and reducing the pressure.

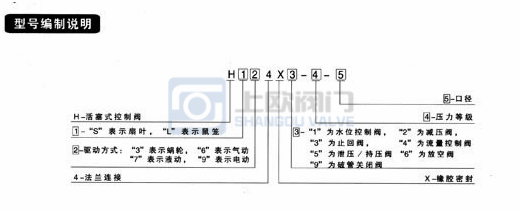

Model: hs941x-16c, hl941x-16c, caliber (DN): 100 ~ 2000 (mm) pressure (PN): 1.0 ~ 10.0 (MPA)

The electric piston type multi-function control valve produced by shangou valve is of piston structure, the regulating mechanism of piston type control valve should be crank slider mechanism, and the sliding block of closing part should be cylindrical or conical piston. The inner cylinder of the valve body can move axially along the center of the pipeline under the guide of the guide rail, thus changing the area of the flow passage to realize the function of regulating the flow rate and reducing the pressure. The connection form with the pipeline is flange connection, and the flange connection size and structure length meet the requirements of corresponding GB.

Piston control valve is composed of valve body, piston, crank, connecting rod, energy dissipation device, valve rod, shaft sleeve, valve seat, sealing ring and other main components.

The valve body of piston control valve is a streamline axisymmetric flow channel. The fluid in the valve body can be well guided without turbulence, which can significantly reduce the noise and vibration of the valve. Ensure that the valve also has good cavitation resistance under high pressure difference, and its allowable cavitation coefficient should not be greater than 0.4.

The piston control valve has excellent linear regulation performance, so that the control system can control the valve through the feedback signal of the outlet pressure transmitter, and keep the outlet pressure constant.

The piston type control valve has reliable sealing performance and ensures no leakage when the control valve is fully closed.

The piston type control valve has no jamming and harmful vibration under normal operation conditions, which ensures the safe and reliable operation of the equipment. The service life is not less than 30 years. The piston control valve has good anti blocking ability. It can be applied to the fluid with sediment and small particle impurities. The piston control valve can ensure the safety and reliability of the whole thrust resistance and avoid harmful vibration under the working conditions of Zui large working pressure difference and dynamic water opening and closing.

The piston control valve is driven by motor. The motor driving device shall have good waterproof performance, flexible action, safety and reliability, and the manual operation torque shall meet the national standard. The electric device of piston control valve includes electric machine, deceleration worm gear, mechanical limit adjusting mechanism, torque control mechanism, travel control mechanism, opening indication mechanism and manual electric conversion device. The electric device of piston type control valve adopts Mechatronics design,

Configure local operation control box.

The transmission device of piston control valve has the following performance:

·Valve overload protection;

·Valve travel protection;

·Manual / electric switching device;

·Valve opening position indication device;

·Valve open and close contacts, contact wire lead out should meet the requirements of local and remote control room.

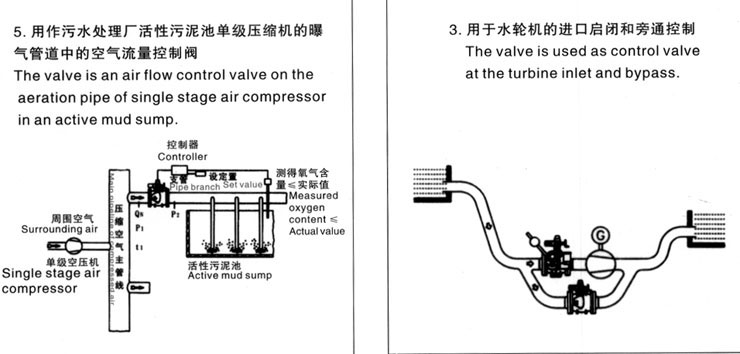

1. Good linearity: due to the special structure design inside the valve body, it has good linearity for the flow control characteristics of the fluid, even in the first 10% stroke, it still has good flow control effect.

2. Anti cavitation and anti vibration: make full use of the principle of fluid dynamics to design the flow passage, eliminate the damage of cavitation and vibration to the pipe network, and greatly improve the service life of valves and pipelines.

3. The design of the valve is not reliable because of the small size of the valve, or the valve can not be closed due to the leakage of small particles.

4. High pressure energy dissipation: even in the case of high pressure difference, the valve can effectively eliminate high pressure energy, reduce high pressure to low pressure, and will not produce vibration and cavitation phenomenon, effectively ensure the service life of the valve.

5. Excellent material selection: the key parts of the valve such as valve seat, stop block, guide rail and other parts are made of special non reinforced bar

Material production, this material wear resistance, cavitation resistance, hardness is three times of ordinary non reinforced.

6. Floating valve seat: the connection between the valve seat and the cone is bonded with special silica gel, which has high viscosity and shear resistance. When the floating seat is sealed, the valve seat has self centering effect, which makes the sealing more reliable.

7. Small fluid resistance: the advanced structure design and reasonable flow distribution of the valve reduce the pressure loss of the whole valve to influence, which is conducive to saving the power consumption of the whole pipe network.

8. Small operating torque: the opening and closing parts of the valve are sleeve gates, whose movement direction is consistent with the flow direction of the main pipe fluid, and the effective stress area is small, so the operating torque required for opening and closing the valve is also very small, and the cost of driving device can be greatly reduced.

9. Long service life: the main seal of the valve is metal, which has reliable sealing, strong resistance to fluid erosion, and is not easy to be damaged by mixed garbage. In addition, most parts are made of stainless steel, so the service life of the valve is greatly improved.

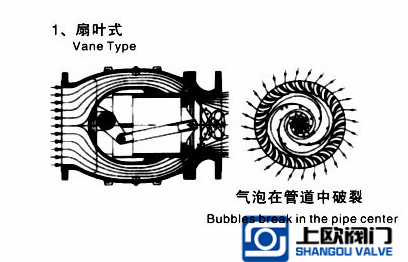

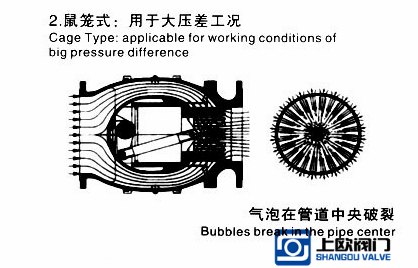

1、 Solve cavitation problem

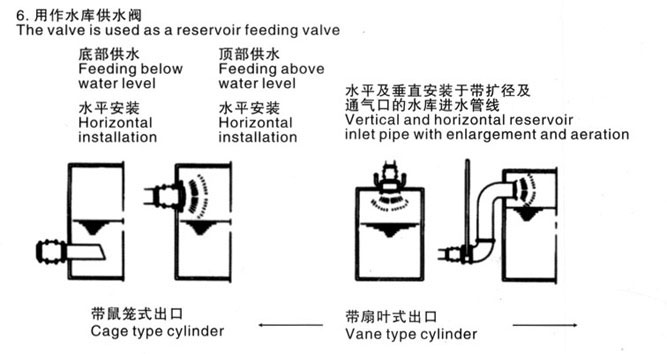

The fan blade is composed of evenly distributed guide vanes, which evenly divides the upstream medium into many small streams and guides them to spiral motion. The medium around the valve body and the adjacent pipeline is forced to change the flow direction, so that the cavitation bubbles are limited in the center of the pipeline and are completely surrounded by water. Even if these bubbles break due to instability, they will not produce any cavitation damage because they are in the center of the pipe instead of the wall of the pipe and valve.

The squirrel cage is an extension of the piston with holes. The cage groove is determined according to the operating conditions. The medium (water) flows through the peripheral nodes of the cage to form multiple streams of high-speed fluid. The jet impinges on each other along the radial center of the cage. Therefore, the cavitation erosion is limited in the center of the cage. The kinetic energy disappears due to collision, and the valve valve and pipeline are damaged by cavitation.

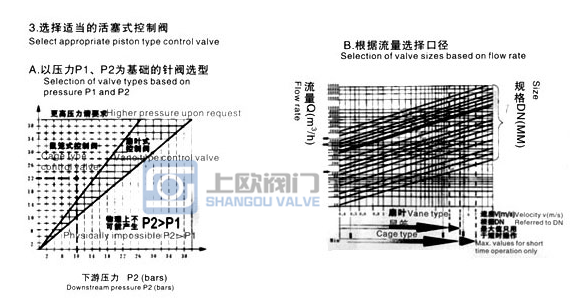

C. The operation conditions are listed, upstream pressure P1 = 22 bar, downstream pressure P1 = 10 bar, flow rate = 130 m3 / h, flow rate = 900 m3 / h, flow rate = 1400 m3 / h

2、 It has linear regulation characteristics

3、 There is no turbulence phenomenon in the flow linear valve body, so there is no vibration.

△P=K·(ρ/2)·V2

In the formula: △ P is the head loss,

Unit: pa91kg / cm2 = 10 Λ 5pa)

V is the velocity in M / s

K is the pressure loss coefficient

ρ is the density in kg / m Λ 3

2. Caliber, pressure grade, medium, temperature

Caliber: DN 100 ~ DN2000

Pressure rating: PN10 ~ PN100

Medium: water, air, natural gas, gas, steam.

Temperature: normal - 10 ℃ - 135 ℃, high temperature as required.

It is suggested that the length of the straight pipe in front of the valve should be at least 3-5 times of the valve diameter, and the length of the downstream straight pipe should be at least 5-10 times of the valve diameter. When it is used as a vent valve, the flange should be strengthened if it is directly emptied; if not, a suction port should be provided downstream.

常用阀门材料允许使用压力明细介绍

常用阀门材料允许使用压力明细说明。常用阀门材质国家标准代号分类

常用阀门材质国家标准代号分类有那些,上欧为您做准确说明,请参.....What is the name.....

The name of the organization t.....Main technical r.....

The main technical requirement.....Bill of material.....

1: Screw plug: Bronze / stainl.....Set up a new ben.....

Full flow streamline design, t.....General technica.....

The adjustment of piston type .....Fast Navigation

Product Line

Recommended Products

Technical Support

Copyright:Shangou Valve Co.,Ltd Record No:; Sitemap

Friendship Links: SenAu Product website